Method for forming platy pieces with negative angle

A negative-angle, plate-shaped technology, which is applied in the forming field of automobile roofs, can solve problems such as cumbersome processing and deformation of mounting holes, and achieve the effects of reducing procedures, improving production efficiency, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

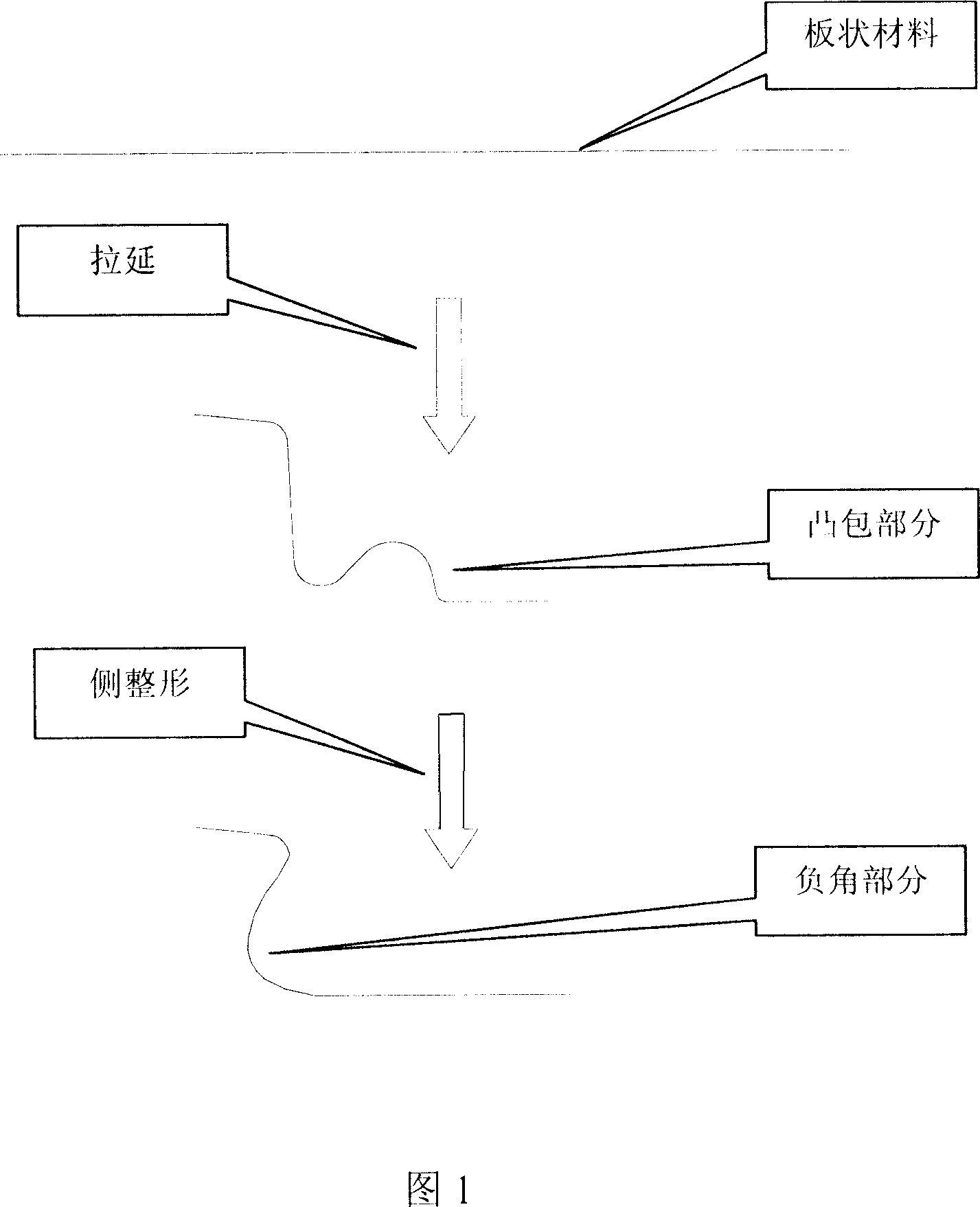

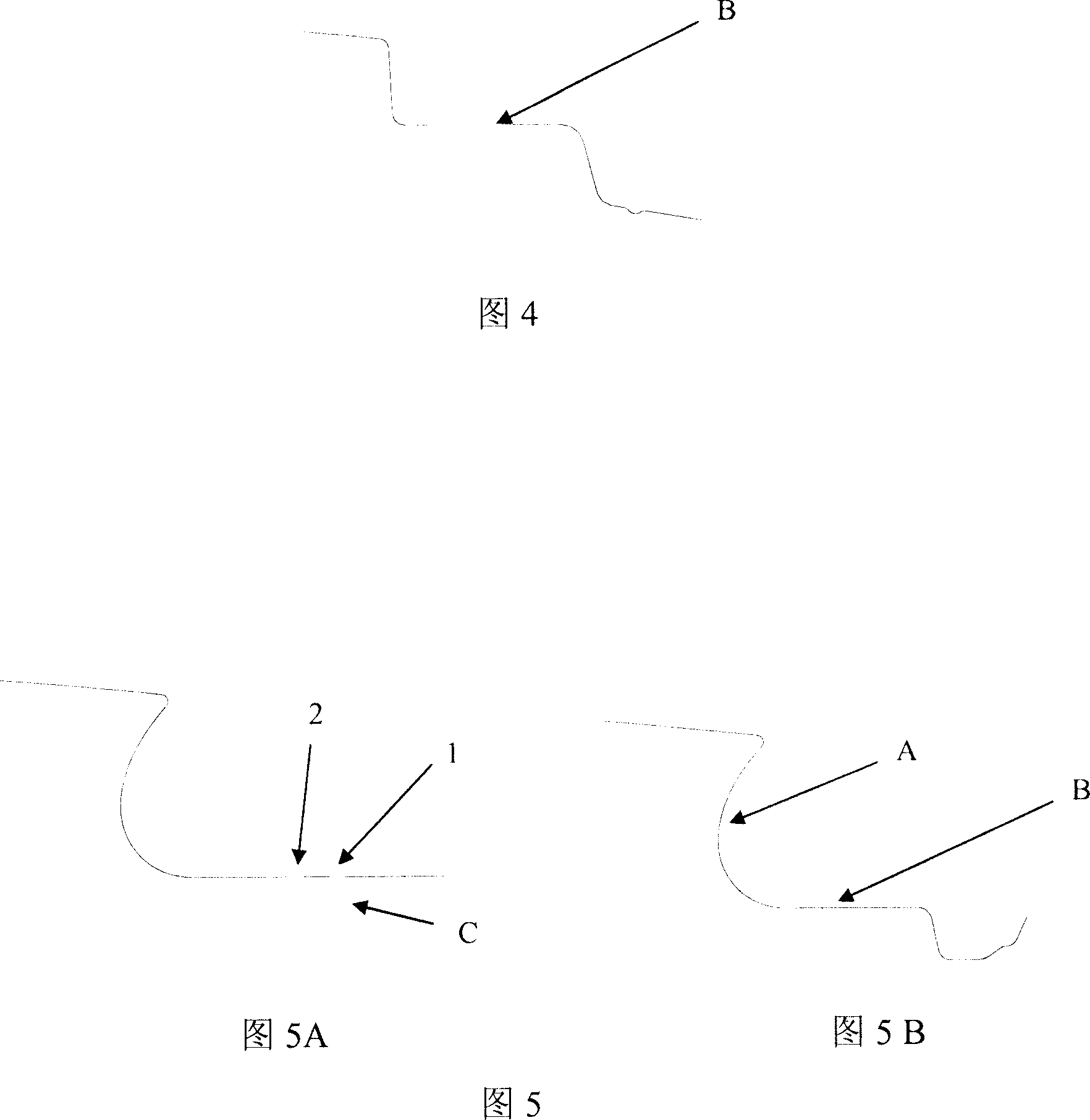

[0023] As shown in Fig. 1, the present invention discloses a method for forming a plate-like product with a negative angle. The method includes drawing the plate-like material to form at least two intersecting surfaces. A convex portion is formed on one face, then side shaping is performed on the other face, and a negative angle portion is formed on the other face while the material of the convex portion is replenished to the negative angle portion.

[0024] Preferably, the included angle between the two intersecting surfaces is 30° to 150°. More preferably, the angle between the two intersecting surfaces is 90° to 100°. Because, if the angle is too large or too small, it is not conducive to drawing the plate-shaped parts.

[0025] Preferably, the size of the convex part is such that when the side is shaped, the material of the convex part is completely supplemented to the negative angle part, so that the material of the workpiece basically does not undergo elongation deforma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com