Method for processing shifting fork of automobile parts

A technology for auto parts and processing methods, applied in the direction of components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problem of short service life, poor product quality, lack of symmetry, position and product hardness Guarantee, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

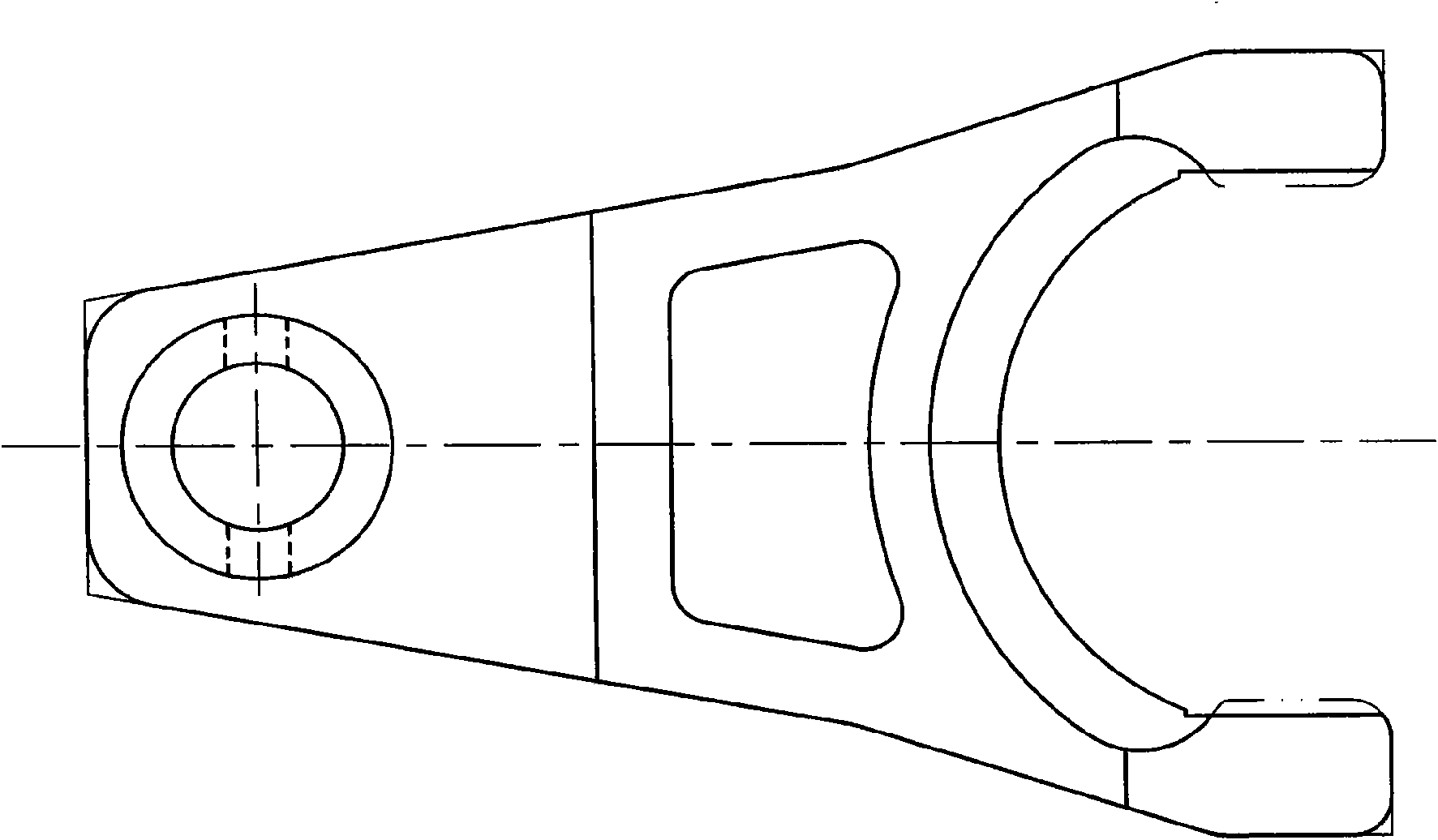

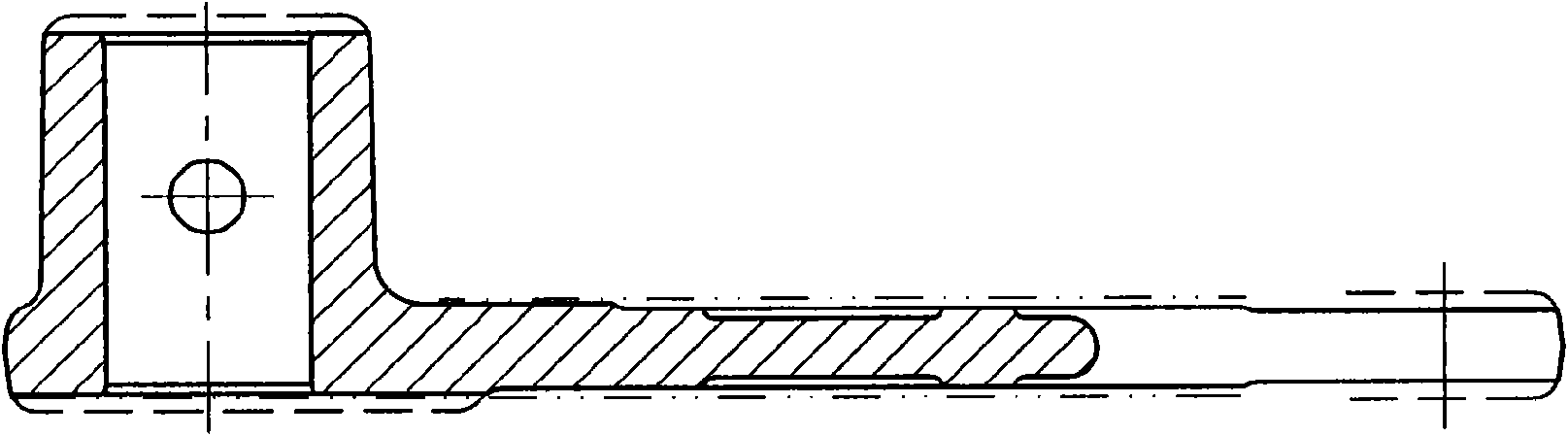

[0006] Below in conjunction with accompanying drawing, the present invention will be further described;

[0007] In the figure, the processing method of the shift fork of auto parts is characterized in that; car: clamp and clamp the large plane on the car, drill through holes, the center of the hole and the center of the blank do not exceed 0.5; the inner side of the car, and control the parts Thickness, turning the end face of the boss and chamfering; boring through holes and chamfering; drawing holes; pulling up the clamps, pulling the bored holes, leaving a honing allowance, and ensuring that the perpendicularity to the large plane does not exceed 0.03; turning: rising core Clamp and clamp the rod, turn the end face of the boss to the total thickness dimension of the drawing, and chamfer; Grind: Grind the clamp and clamp, grind the plane of the two feet, control the thickness of the two feet and grind the upper end to the center of the hole; similarly , adjust the surface a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com