Method for exploiting compact dry heat rock geothermal energy by utilizing long horizontal well self-circulation structure

A technology of long horizontal wells and hot dry rocks, applied in geothermal energy power generation, geothermal energy systems, heat collectors using groundwater as a working fluid, etc., to improve corrosion resistance and heat exchange capabilities, improve heat exchange efficiency, and be economical benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0034] A method for self-circulating exploitation of compact hot dry rock geothermal energy by using a long horizontal well, the specific steps are as follows:

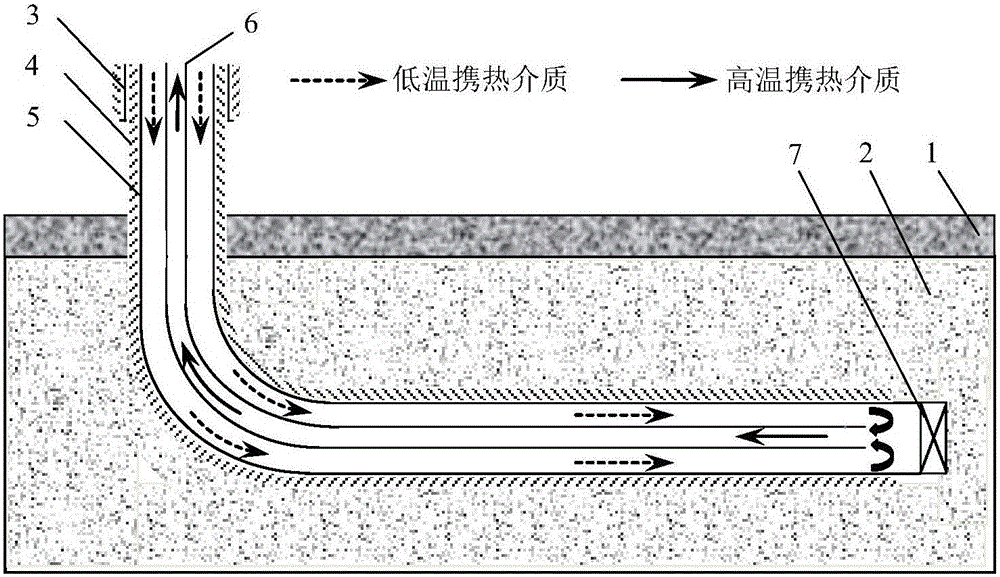

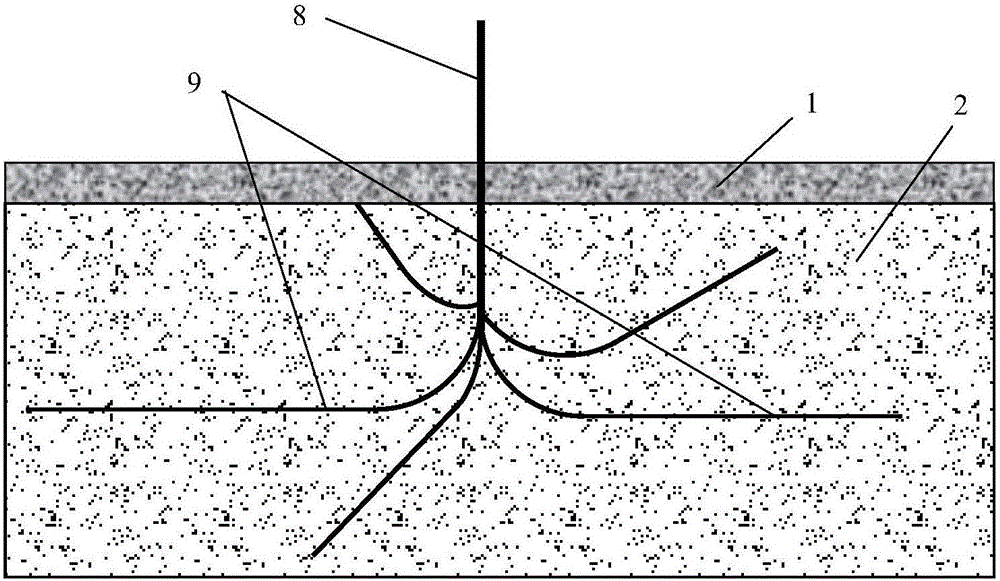

[0035] (1) if figure 1 As shown, the hot dry rock reservoir 2 is selected, and a conventional tower drilling tool is used in the surface area, and a drill bit larger than 20 inches is used to drill. Used to protect the wellhead and isolate the upper aquifer. During the drilling process, high temperature resistant drilling fluid should be used for drilling;

[0036] (2) Replace the drill bit with a smaller drill bit size greater than 12 inches, and drill the vertical section 8 of the horizontal well. After drilling into the hot dry rock reservoir 2, continue drilling for more than 10m, and then use the deflection tool to deflect and drill water In the horizontal section 9 of the flat well, during the drill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com