Method for preparing guanidine-gum fracturing-liquid nanometer cross-linking agent

A guar gum fracturing fluid and cross-linking agent technology, applied in the field of nanomaterials, can solve the problems of substandard temperature resistance and shear resistance residue content, poor temperature resistance and shear resistance, and increased flowback difficulty, etc. Excellent overall cross-linking performance, good temperature resistance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

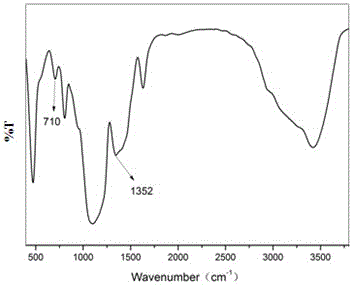

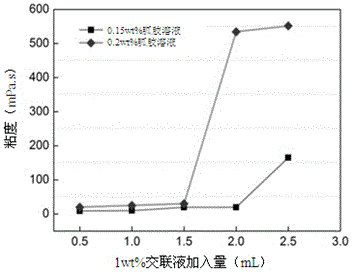

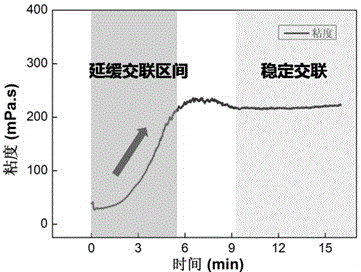

[0021] A preparation method of guar gum fracturing fluid nano-crosslinking agent, comprising the following steps:

[0022] (1) Prepare a sodium silicate solution with a mass fraction of 48.8%, take 50g of a sodium silicate solution with a mass fraction of 48.8%, and another 4.5g of γ-aminoethylaminopropyltrimethoxysilane, and add them to 150ml In ethanol, add dilute hydrochloric acid dropwise to adjust the pH to 11, heat up to 60°C, keep stirring for 3 hours, then filter, wash with deionized water, and rinse with xylene to obtain a reactive nano-silica filter cake, which can be reacted The solid content of the nano-silica filter cake is 20%;

[0023] (2) Weigh 60 grams of the reactive nano-silica filter cake obtained in step (1), add it to 50 milliliters of xylene, heat up to 50°C, keep stirring for 0.5 hours, add 3 grams of boric acid and heat up to 110°C , keep stirring for 2 hours;

[0024] (3) Filter the product obtained in step (2), wash with ethanol, and then dry at 10...

Embodiment 2

[0030] A preparation method of guar gum fracturing fluid nano-crosslinking agent, comprising the following steps:

[0031] (1) Configure a sodium silicate solution with a mass fraction of 30%, take 60 grams of a sodium silicate solution with a mass fraction of 30%, and take another 4 grams of anilinomethyltriethoxysilane and 1 gram of hexamethyldisilane Azane was added to a mixture of 150 milliliters of deionized water and 20 milliliters of ethanol, dilute hydrochloric acid was added dropwise to adjust the pH to 9, the temperature was raised to 70°C, and kept stirring for 5 hours, then filtered, washed with deionized water, and free Rinse with water and ethanol to obtain a reactive nano-silica filter cake, and the solid content of the reactive nano-silica filter cake is 24%;

[0032] (2) Weigh 50 grams of the reactive nano-silica filter cake obtained in step (1), add 100 milliliters of toluene and ethanol mixture, heat up to 50 ° C, keep stirring for 0.5 hours, add 1.2 grams o...

Embodiment 3

[0038]A preparation method of guar gum fracturing fluid nano-crosslinking agent, comprising the following steps:

[0039] (1) Configure a sodium silicate solution with a mass fraction of 40%, take 25 grams of a sodium silicate solution with a mass fraction of 40%, add 150 ml of deionized water and 20 ml of ethanol to the mixture, add dilute sulfuric acid dropwise to adjust the pH To 10, add 3.5 grams of γ-aminopropyltrimethoxysilane, raise the temperature to 80 ° C, keep stirring for 9 hours, then filter, wash with deionized water, and rinse with acetone to obtain a reactive nano-silica filter cake , the solid content of the reactive nano silica filter cake is 15%;

[0040] (2) Weigh 60 grams of the reactive nano-silica filter cake obtained in step (1), add it to 50 milliliters of acetone, heat up to 50 ° C, keep stirring for 1 hour, add 4.5 grams of boric acid and heat up to 105 ° C, Insulated and stirred for 3 hours;

[0041] (4) Filter the product obtained in step (3), wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com