Epoxy modified anionic/nonionic waterborne polyurethane resin and preparation method thereof

A water-based polyurethane and epoxy modification technology, applied in polyurea/polyurethane coatings, small raw hide/big raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve modification Problems such as poor stability of water-based polyurethane dispersions, to achieve excellent stability, excellent water resistance, and enhanced cohesive energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

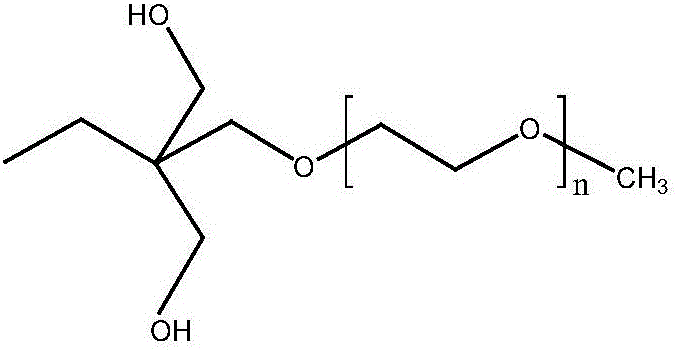

Method used

Image

Examples

Embodiment 1

[0044] In a four-neck flask equipped with an electric stirrer, a reflux condenser, and a mercury thermometer, add 200 g of polytetrahydrofuran ether glycol (PTMG) with a molecular weight of 2000, dehydrate in vacuum at 120°C for 2 hours, cool down to 70°C, and add iso Fluorone diisocyanate (IPDI) 111.15g and catalyst dibutyltin dilaurate (DBTDL) 0.10g were reacted at 90°C for 1-2 hours to obtain a primary polymer. After cooling down to 70°C, add 9.6g of 1,4-butanediol (BDO), 17.0g of dimethylolpropionic acid (DMPA), 30.0g of N-methylpyrrolidone (NMP) and 50.0g of acetone, and keep warm for 3.0 ~4.0h, after NCO was titrated to the end point by di-n-butylamine method, the temperature of the system was lowered to 50°C, and 12.83g of triethylamine (TEA) and 50.0g of acetone were added to neutralize and form a salt. The prepolymer obtained after neutralization was shear dispersed into 620.0g deionized water at 2000rpm for emulsification for about 10min, then 8.0g of ethylenediamine...

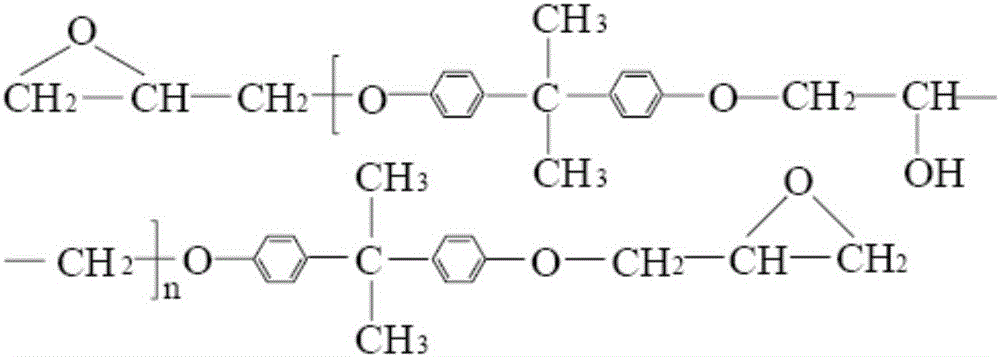

Embodiment 2

[0046] In a four-neck flask equipped with an electric stirrer, a reflux condenser, and a mercury thermometer, add 200 g of polytetrahydrofuran ether glycol (PTMG) with a molecular weight of 2000, dehydrate in vacuum at 120°C for 2 hours, cool down to 70°C, and add iso Fluorone diisocyanate (IPDI) 111.15g and catalyst dibutyltin dilaurate (DBTDL) 0.10g were reacted at 90°C for 1-2 hours to obtain a primary polymer. After cooling down to 70°C, add 1,4-butanediol (BDO) 8.34g, dimethylolpropionic acid (DMPA) 17.0g, epoxy resin (E-20) 14.0g, N-methylpyrrolidone (NMP ) 30.0g and acetone 50.0g, keep warm for 3.0-4.0h, titrate NCO to the end point with di-n-butylamine method, cool down the system to 50°C, add 12.83g triethylamine (TEA) and 50.0g acetone to neutralize and form a salt . The prepolymer obtained after neutralization was shear dispersed into 648.0g deionized water at 2000rpm for emulsification for about 10min, then 8.0g of ethylenediamine was added for chain extension for...

Embodiment 3

[0048] In a four-neck flask equipped with an electric stirrer, a reflux condenser, and a mercury thermometer, add 200 g of polytetrahydrofuran ether glycol (PTMG) with a molecular weight of 2000, dehydrate in vacuum at 120°C for 2 hours, cool down to 70°C, and add iso Fluorone diisocyanate (IPDI) 111.15g and catalyst dibutyltin dilaurate (DBTDL) 0.10g were reacted at 90°C for 1-2 hours to obtain a primary polymer. After cooling down to 70°C, add 1,4-butanediol (BDO) 6.82g, dimethylol propionic acid (DMPA) 17.0g, epoxy resin (E-44) 14.0g, N-methylpyrrolidone (NMP ) 30.0g and acetone 50.0g, keep warm for 3.0-4.0h, titrate NCO to the end point with di-n-butylamine method, cool down the system to 50°C, add 12.83g triethylamine (TEA) and 50.0g acetone to neutralize and form a salt . The prepolymer obtained after neutralization was shear dispersed into 645.0g deionized water at 2000rpm for emulsification for about 10min, then 8.0g of ethylenediamine was added to extend the chain fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com