Preparation method of high-transparency and high-barrier cellulose paper

A cellulose paper and cellulose technology, applied in special paper, paper, papermaking, etc., can solve the problems of unsuitable recycling of solvents, greenness, etc., and achieve the effects of reducing agglomeration, reducing production costs, and low aspect ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

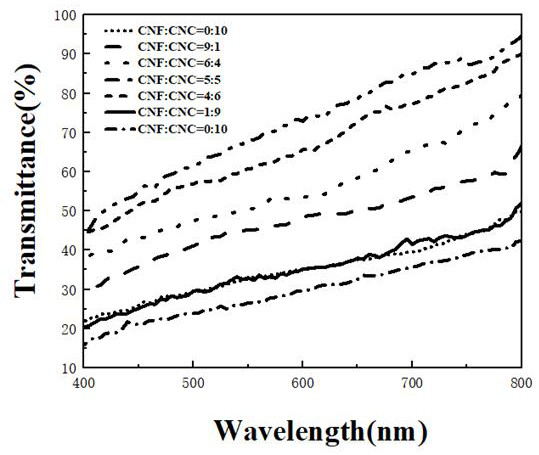

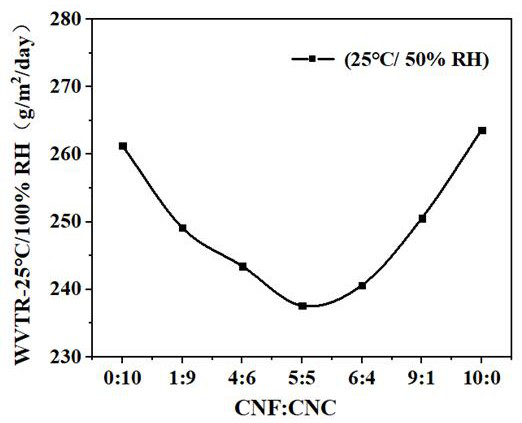

[0025] Weigh 0.5 g of cellulose nanocrystal (CNC) solution and 0.5 g of cellulose nanofibril (CNF) solution in a dry mass, place them in a beaker, and ultrasonicate for 1 hour to disperse the CNC / CNF mixed solution. homogeneously, to obtain a mixed solution of all nanocellulose. After the filter membrane is placed in the sand core funnel, the uniformly mixed whole nanocellulose solution is poured into the sand core funnel, and suction filtered for 1.5 hours to a relatively dry state. Then the cellulose and filter membrane obtained by suction filtration were placed on a polytetrafluoroethylene plate, and placed in an oven, and dried at 35° C. for 3 hours. Finally, the water-based mixed filter membrane with a thickness of 0.45 μm and a diameter of 47 mm was peeled off to obtain a highly transparent and high-barrier cellulose paper.

Embodiment 2

[0027] Weigh the cellulose nanocrystal (CNC) solution with a dry weight of 0.1 g and the cellulose nanofibril (CNF) solution with a dry weight of 0.9 g, place them in a beaker, and ultrasonicate for 2 hours to disperse the CNC / CNF mixed solution homogeneously, to obtain a mixed solution of all nanocellulose. After the filter membrane is placed in the sand core funnel, the uniformly mixed whole nanocellulose solution is poured into the sand core funnel, and suction filtered for 6 hours to a relatively dry state. Then the cellulose paper and filter membrane obtained by suction filtration were placed on a polytetrafluoroethylene plate and placed in an oven for drying treatment at 50° C. for 1 h. Finally, the water-based mixed filter membrane with a thickness of 0.45 μm and a diameter of 47 mm was peeled off to obtain a highly transparent and high-barrier cellulose paper.

Embodiment 3

[0029] Weigh the cellulose nanocrystal (CNC) solution with a dry mass of 0.9 g and the cellulose nanofibril (CNF) solution with a dry mass of 0.1 g, place them in a beaker, and ultrasonicate for 0.5 h to make the CNC / CNF mixed solution Disperse evenly to obtain a mixed solution of all nanocellulose. After the filter membrane is placed in the sand core funnel, the uniformly mixed whole nanocellulose solution is poured into the sand core funnel, and suction filtered for 6 hours to a relatively dry state. Then the cellulose paper and filter membrane obtained by suction filtration were placed on a polytetrafluoroethylene plate, and placed in an oven for drying treatment at 15° C. for 8 hours. Finally, the water-based mixed filter membrane with a thickness of 0.45 μm and a diameter of 47 mm was peeled off to obtain a highly transparent and high-barrier cellulose paper.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com