Acrylate hot melt adhesive composition and preparation method of hot melt adhesive by UV (ultraviolet) crosslinking

An acrylate and acrylate technology, which is applied in the preparation of UV cross-linked acrylate hot melt adhesives and the composition field of acrylate hot melt adhesives, can solve the problem of insufficient crosslinking degree, poor temperature resistance, and bonding strength. Less problems, to achieve the effect of good weather resistance, high heat resistance, excellent bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

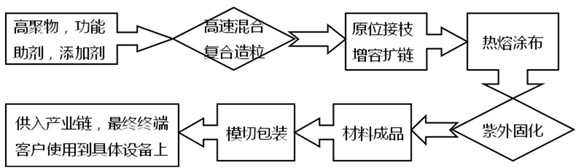

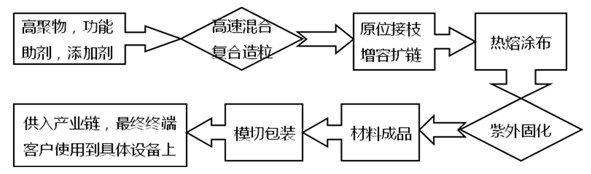

[0023] The preparation method of UV cross-linked acrylate hot melt adhesive is characterized in that: in the method, the acrylate copolymer with ultraviolet photoinitiating functional group and copolyester are compounded to obtain a hot melt adhesive composition, and the composition is hot melt coated Partially cross-linked hot-melt adhesives are obtained by ultraviolet cross-linking.

[0024] The structural unit glycidyl methacrylate in the acrylate copolymer is 1-10%, the optimal ratio is 3-5%; the p-benzophenone containing vinyl group or (meth)acrylate group is 0.5-5% , the optimal ratio is 1-3%, the vinyl or (meth)acrylate group is mainly in the para position, and the (meth)acrylate group is connected to the benzene ring through a phenolic oxygen bond; other copolymerized structural units of the acrylate copolymer Also includes one or more of the following monomers, (meth) hydroxyethyl acrylate, (meth) hydroxypropyl acrylate, (meth) methyl acrylate, (meth) ethyl acrylate, ...

Embodiment 1

[0027] Take 42 parts of ethyl acrylate, 49 parts of butyl acrylate, and 3 parts of glycidyl methacrylate by weight percentage (the epoxy group is used to carry out chain extension reaction with the carboxyl group of the copolyester, and at the same time reduce the hydrolysis of the copolyester), 1 part of 4-vinyl-4-methoxybenzophenone (UV initiating group, generating free radicals after cleavage), 5 parts of isooctyl acrylate, 150 parts of solvent ethyl acetate and initiator azobisisobutyl Nitrile 0.5 parts. Put the materials into a four-necked flask, which is equipped with a thermometer, reflux condenser, agitator and nitrogen conduit temperature, and the system is copolymerized at 62°C for 6 hours under the protection of nitrogen, and then copolymerized at 76°C for 8 hours to obtain 40% solid content of the acrylate copolymer solution. Then, the copolymer solution was coated to a thickness of 0.150 mm with a spatula under dark conditions, and then the solvent and residual m...

Embodiment 2

[0029] Take 42 parts of ethyl acrylate, 47 parts of butyl acrylate, 3 parts of glycidyl methacrylate, 3 parts of 4-vinyl-4-methoxybenzophenone, 5 parts of isooctyl acrylate, solvent 150 parts of ethyl acetate and 0.4 parts of initiator azobisisobutyronitrile. Adopt the technique of embodiment 1 to make copolymer adhesive film. The measured weight-average molecular weight of the acrylate copolymer was 290,000 g / mol, the glass transition temperature was -25°C, and the melt viscosity was 31 Pa.S at 160°C. Wherein in the solid, the weight content of glycidyl methacrylate is 3%, the weight content of 4-vinyl-4-methoxybenzophenone is 3%, and the weight content of initiator azobisisobutyronitrile is 0.4%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Glass transition temperature | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

| Melt viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com