Environment-friendly waterless offset ink

A waterless offset printing, environmentally friendly technology, applied in the field of printing ink, can solve the problems of low printing speed, slow curing speed, poor physical and chemical properties of ink film formation, and achieve good printing quality, high cohesive energy, and good ink flow performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

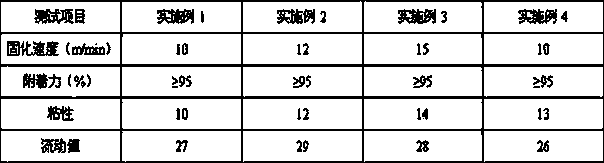

Examples

Embodiment 1

[0012] 40 parts of polymerized rosin resin

[0013] Adhesive 5 parts

[0014] 10 parts refined linseed oil

[0015] Photoinitiator 6 parts

[0016] Phthalocyanine blue 10 parts

[0017] Anti-wear agent 0.5 parts

[0018] Neutralizer 1 part

[0019] Auxiliary 0.1 parts.

[0020] Add polymerized rosin resin, binder, refined linseed oil, photoinitiator, anti-wear agent, neutralizer and auxiliary agent in sequence according to the above mass parts, stir at high speed until the powder is completely dissolved, add phthalocyanine blue pigment, and stir After uniformity, disperse at high speed for 10-200 minutes, then grind and roll, transfer to the dispersion bucket after grinding, and disperse at high speed for 10-200 minutes.

Embodiment 2

[0022] 45 parts of polymerized rosin resin

[0023] Adhesive 10 parts

[0024] 15 parts refined linseed oil

[0025] Photoinitiator 8 parts

[0026] Phthalocyanine blue 12 parts

[0027] Anti-wear agent 2 parts

[0028] Neutralizer 2 parts

[0029] Auxiliary 0.5 parts.

[0030] Add polymerized rosin resin, binder, refined linseed oil, photoinitiator, anti-wear agent, neutralizer and auxiliary agent in sequence according to the above mass parts, stir at high speed until the powder is completely dissolved, add phthalocyanine blue pigment, and stir After uniformity, disperse at high speed for 10-200 minutes, then grind and roll, transfer to the dispersion bucket after grinding, and disperse at high speed for 10-200 minutes.

Embodiment 3

[0032] 48 parts of polymerized rosin resin

[0033] Adhesive 13 parts

[0034] 20 parts refined linseed oil

[0035] Photoinitiator 10 parts

[0036] Phthalocyanine blue 12 parts

[0037] Anti-wear agent 4 parts

[0038] Neutralizer 2 parts

[0039] Auxiliary 1 part.

[0040] Add polymerized rosin resin, binder, refined linseed oil, photoinitiator, anti-wear agent, neutralizer and auxiliary agent in sequence according to the above mass parts, stir at high speed until the powder is completely dissolved, add phthalocyanine blue pigment, and stir After uniformity, disperse at high speed for 10-200 minutes, then grind and roll, transfer to the dispersion bucket after grinding, and disperse at high speed for 10-200 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com