Peelable anti-condensation material as well as preparation method and application thereof

An anti-condensation and raw material technology, applied in fire-resistant coatings, coatings, etc., can solve the problems of inability to quickly cure, poor flame retardant insulation, poor peelability, etc., to achieve excellent comprehensive performance, wide application range, flame retardant The effect of insulation comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

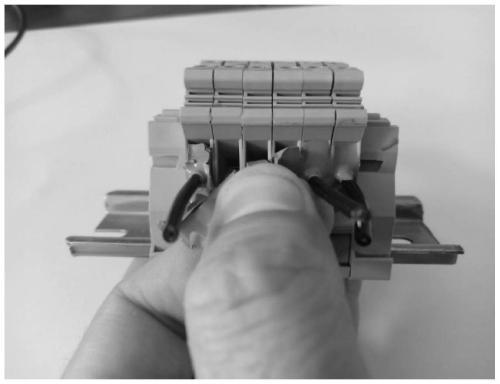

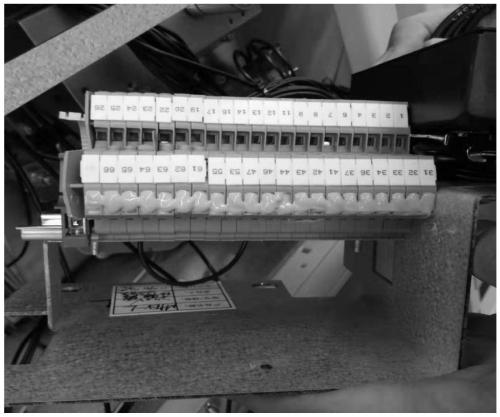

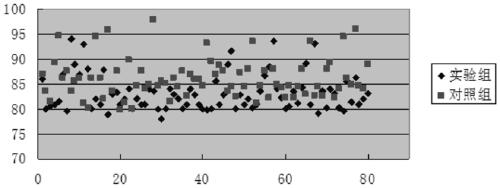

Method used

Image

Examples

preparation example 1

[0065] Add 12.2g of A-174, 22g of deionized water, 13g of isopropanol, 3.5g of OP-10, 3.7g of sodium lauryl sulfate, 0.5g of potassium persulfate into a 250mL reaction vessel, start stirring, and slowly add 13.4g of The mixed solution of perfluorododecyl ethyl methacrylate (that is, the compound with n=11 in the above formula (II)) dissolved in 50mL of toluene was dropped within 1 hour, and the polymerization reaction was carried out at 70-100°C for 4 -6 hours to obtain a viscous liquid, which is the silicone-modified fluorine-containing acrylate copolymer, with a weight average molecular weight of 6500 and a viscosity of 1100 mPa·s, hereinafter referred to as modified resin A12.

preparation example 2

[0067] The preparation conditions and method are the same as in Preparation Example 1, except that 13.4 g of perfluorododecyl is replaced by 13.9 g of perfluorohexadecyl ethyl methacrylate (i.e. the compound of n=15 in the above formula (II)) base ethyl methacrylate to obtain a silicone-modified fluorine-containing acrylate copolymer with a weight average molecular weight of 7300 and a viscosity of 1300 mPa·s, which is called modified resin A16.

preparation example 3

[0069] The preparation conditions and method are the same as in Preparation Example 1, except that 13.4 g of perfluorododecylmethyl is replaced by 12.7 g of perfluoroheptyl ethyl methacrylate (i.e. the compound of n=6 in the above formula (II)) Ethyl acrylate to obtain a silicone-modified fluorine-containing acrylate copolymer, its weight-average molecular weight is 6300, and its viscosity is 1100mPa·s, which is hereinafter referred to as modified resin A7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com