RF plasma-enhanced deposition of fluorinated films

a fluorinated film, enhanced technology, applied in the direction of plasma technique, transportation and packaging, synthetic resin layered products, etc., can solve the problems of reducing the efficiency of the molecular recognition process, teflon is not soluble in any solvent, and the adhesion of teflon particles suspended in organic and inorganic media and teflon-like materials dissolved in organic solvents are often not satisfactory, so as to prevent or minimize surface oxid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

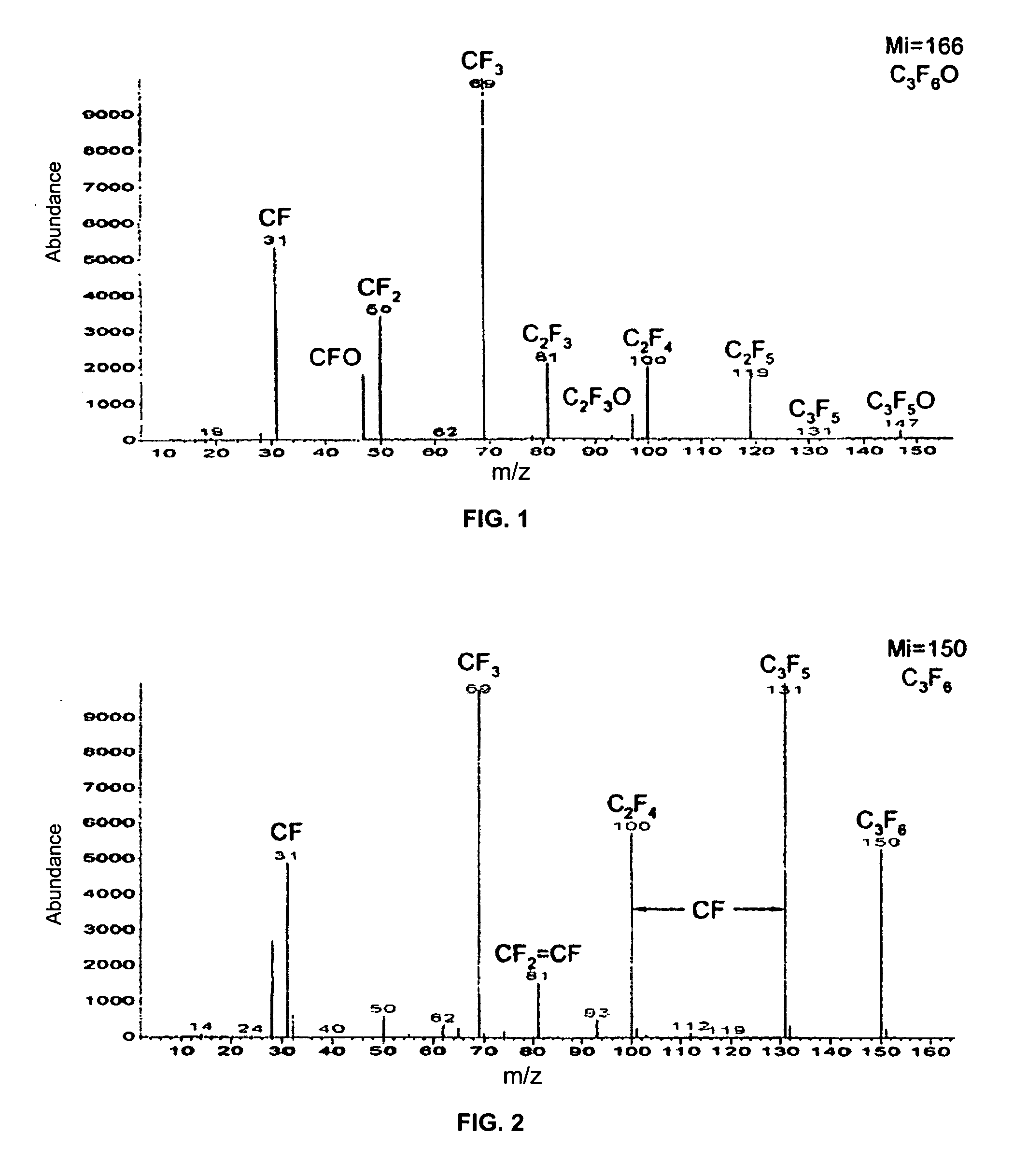

Production of a Fluorinated Thin Film on a Stainless Steel Substrate Using HFPO as a Precursor Gas.

[0052] A fluorinated film was deposited on a stainless steel substrate using precursor molecules of HFPO. The RF plasma parameters during the initial plasma-mediated deposition step were as follows: 1) precursor gas pressure=200 Torr; 2) period=1000 msec; duty=30%; power=100 Watts; and plasma exposure time=5 minutes. The surface active sites on the resulting fluorinated film were quenched using a post-plasma environment of HFPO at a pressure of 1 Torr for about 30 minutes. ESCA analysis of the resulting hydrophobic fluorinated surface film revealed a carbon content of 38.5 atomic percent, a fluorine content of 60 atomic percent and an oxygen content of 1.5 atomic percent. The water contact angle on the hydrophobic surface film was 116°.

example 2

Production of a Fluorinated Thin Film on a Stainless Steel Substrate Using HFPO as a Precursor Gas.

[0053] A fluorinated film was deposited on a stainless steel substrate using precursor molecules of HFPO. The RF plasma parameters during the initial plasma-mediated deposition step were as follows: 1) precursor gas pressure=200 Torr; 2) period=1000 msec; duty=15%; power=100 Watts; and plasma exposure time=5 minutes. The surface active sites on the resulting fluorinated film were quenched using a post-plasma environment of HFPO at a pressure of 1 Torr for about 30 minutes. ESCA analysis of the resulting hydrophobic fluorinated surface film revealed a carbon content of 37.3 atomic percent, a fluorine content of 61.3 atomic percent and an oxygen content of 1.4 atomic percent. The water contact angle on the hydrophobic surface film was 115°.

example 3

Production of a Fluorinated Thin Film on a Stainless Steel Substrate Using HFPP as a Precursor Gas.

[0054] A fluorinated film was deposited on a stainless steel substrate using precursor molecules of HFPP. The RF plasma parameters during the initial plasma-mediated deposition step were as follows: 1) precursor gas pressure=200 Torr; 2) period=800 μsec; duty=30%; power=100 Watts; and plasma exposure time=5 minutes. The surface active sites on the resulting fluorinated film were quenched using a post-plasma environment of HFPP at a pressure of 1 Torr for about 30 minutes. ESCA analysis of the resulting hydrophobic fluorinated surface film revealed a carbon content of 41.7 atomic percent, a fluorine content of 57.5 atomic percent and an oxygen content of 0.8 atomic percent. The water contact angle on the hydrophobic surface film was 114°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Water contact angle | aaaaa | aaaaa |

| Percent by atom | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com