Formation of high quality dielectric films of silicon dioxide for sti: usage of different siloxane-based precursors for harp II-remote plasma enhanced deposition processes

一种等离子、前体的技术,应用在金属材料涂层工艺、电路、电气元件等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

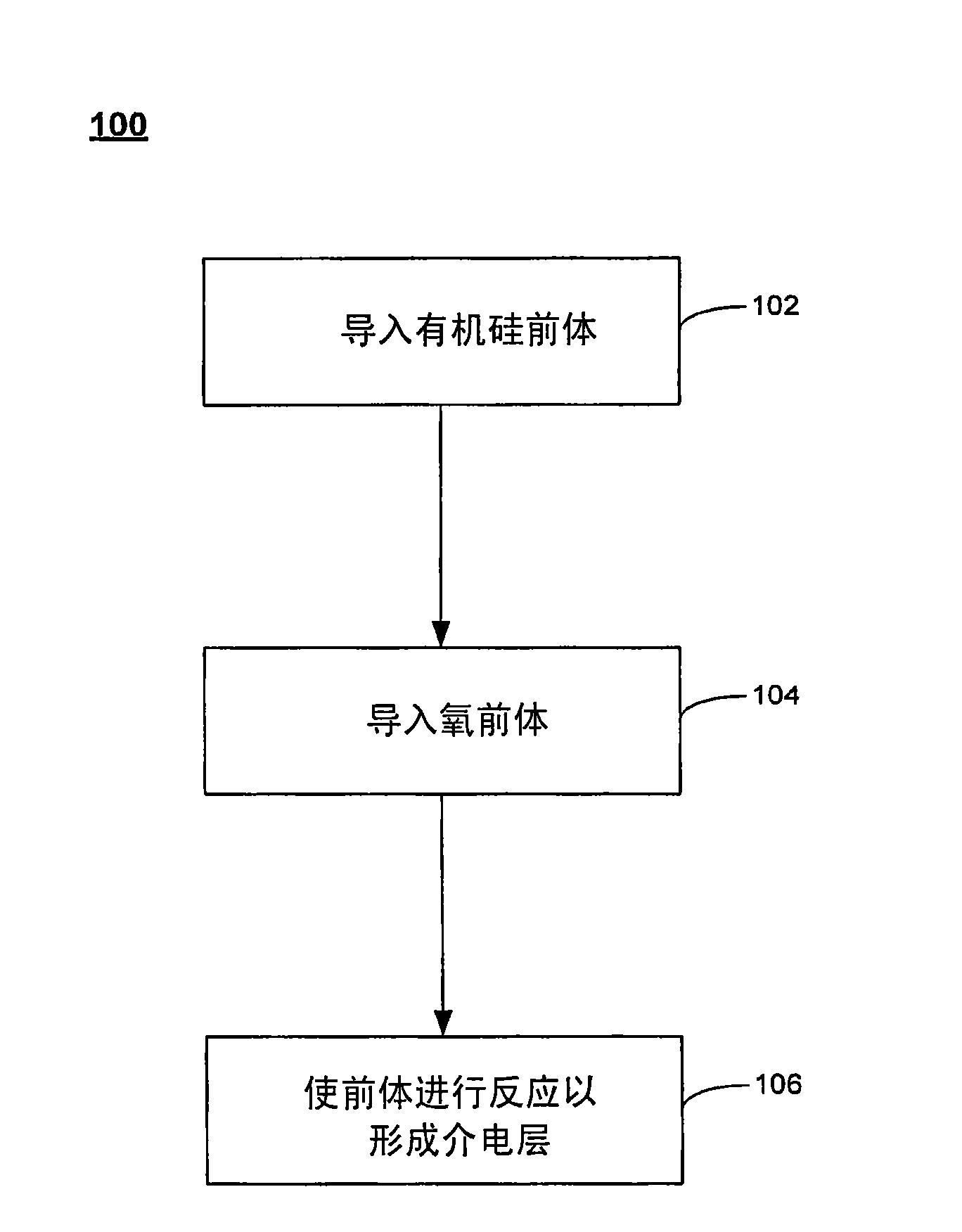

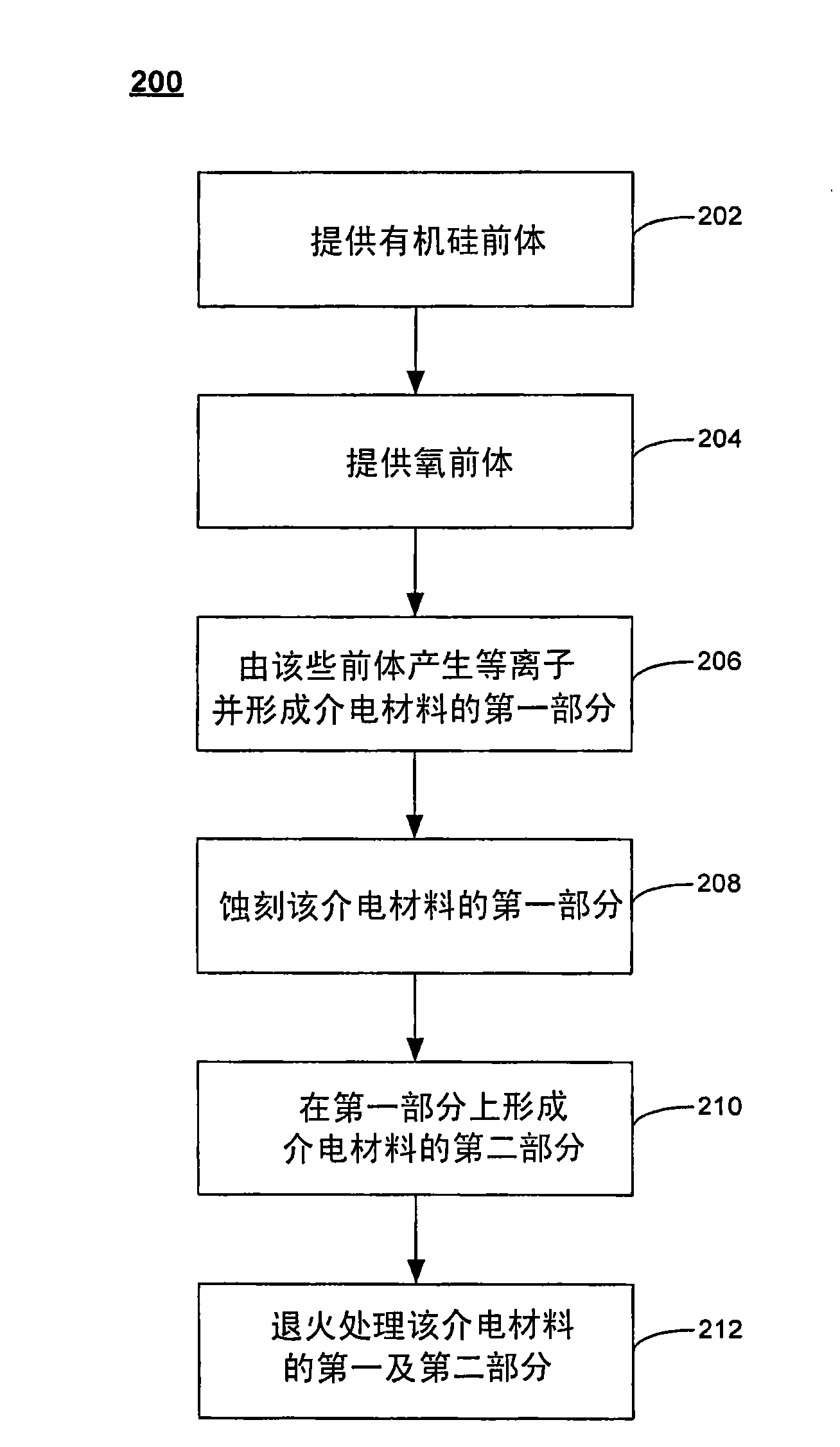

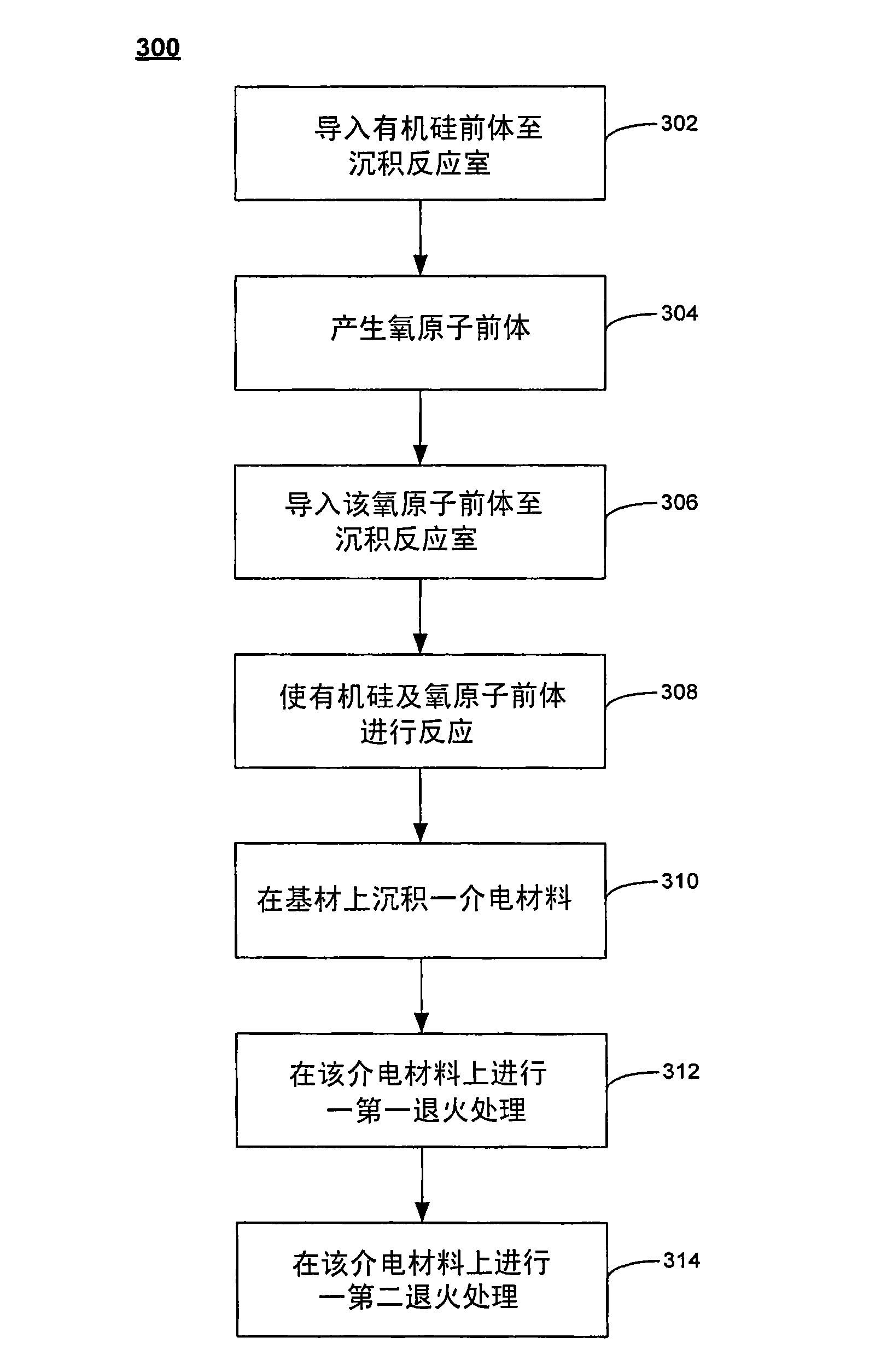

[0045] This specification describes systems and methods for depositing dielectric materials in gaps and on surfaces on a substrate. The dielectric material can be formed from organosilicon compounds having a lower ratio of carbon atoms to silicon atoms (C:Si ratio) than conventional tetraethoxysiloxane (TEOS). Dielectric films formed by combining such compounds with oxygen precursors generally have lower carbon content, porosity, and WERRs than as-deposited TEOS silicon oxide. This makes the film less prone to cracking, void formation, water absorption and / or shrinkage than TEOS oxide films.

[0046] The organosilicon compound may also have an oxygen-to-silicon atom ratio (O:Si ratio) equal to or greater than that of TEOS. Organosilicon precursors with low C:Si ratios and high O:Si ratios can produce higher quality silicon oxide films with lower carbon content than conventional oxides using purely TEOS as the silicon precursor. Embodiments also include organosilicon precurso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| deposition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com