Methods for leaching valuable metals from waste lithium ion ternary positive electrode material and preparing ternary positive electrode material precursor

A cathode material, lithium ion technology, applied in the field of preparation of ternary cathode material precursor, can solve the problems of increasing economic cost and environmental pressure, increasing the difficulty of wastewater treatment, corrosion of production equipment, etc., to avoid secondary solid waste and wastewater , cost reduction and low acid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

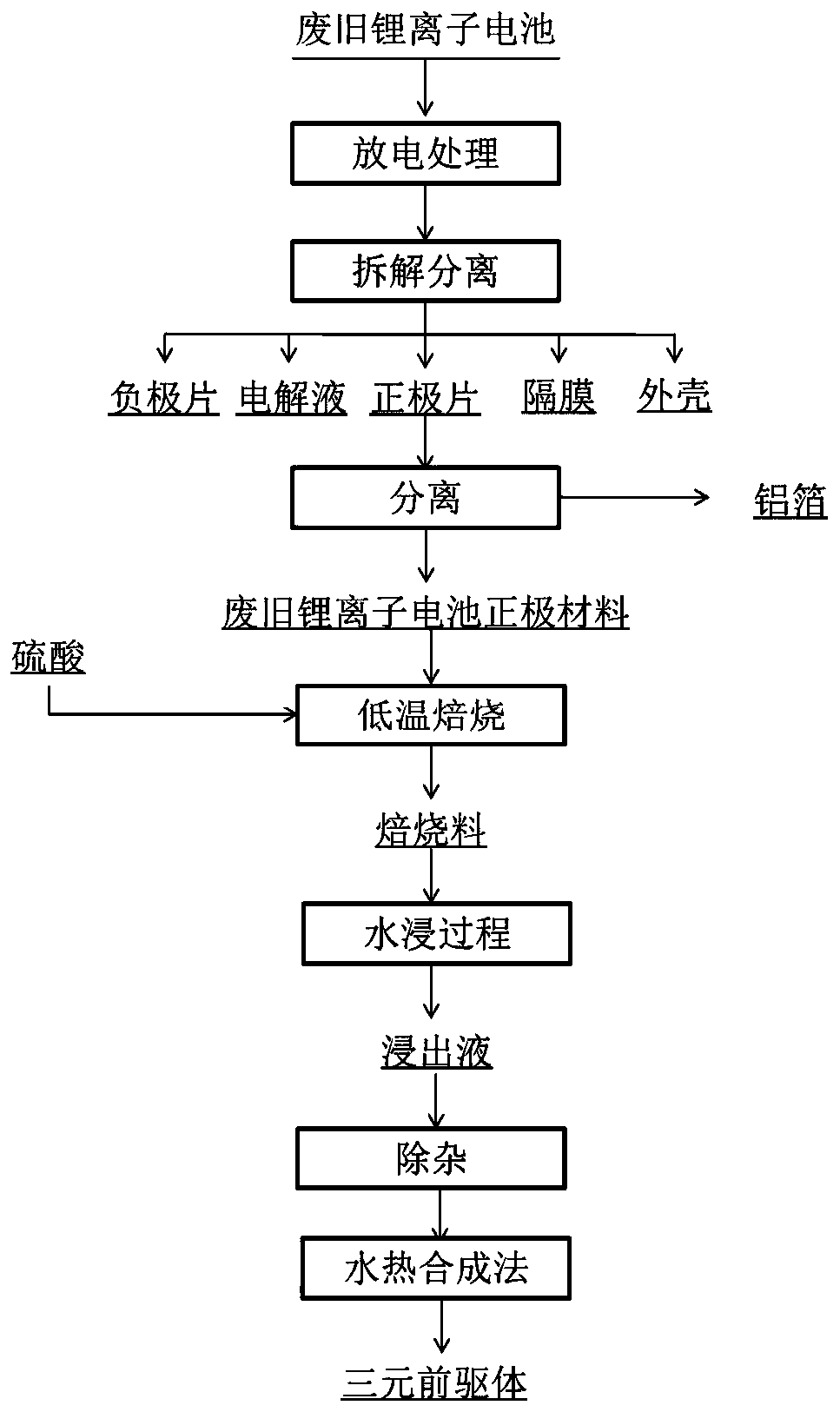

[0043] A method of the present invention for leaching valuable metals from waste lithium ion ternary positive electrode materials and preparing the leaching solution into a ternary positive electrode material precursor, the process flow chart is as follows figure 1 As shown, the specific steps are as follows:

[0044] (1) Put the waste ternary lithium-ion battery into 120g / L salt water for discharge treatment, disassemble and remove the shell, separate the positive electrode sheet, negative electrode sheet, diaphragm, and electrolyte; then put the positive electrode active material on the positive electrode sheet and the current collector Aluminum foil is separated, and the separated waste lithium-ion battery positive electrode active material is ball-milled to obtain powder;

[0045] (2) Mix the powder and water according to 1:0.4 (mass ratio) to make the powder wet;

[0046] (3) Add sulfuric acid with a concentration of 80% to the wet material to mix (the molar ratio of pow...

Embodiment 2

[0055] A method of the present invention for leaching valuable metals from waste lithium ion ternary positive electrode materials and preparing the leaching solution into a ternary positive electrode material precursor, the specific steps are as follows:

[0056] (1) Put the waste ternary lithium-ion battery into 120g / L salt water for discharge treatment, disassemble and remove the shell, separate the positive electrode sheet, negative electrode sheet, diaphragm, and electrolyte; then put the positive electrode active material on the positive electrode sheet and the current collector Aluminum foil is separated, and the separated waste lithium-ion battery positive electrode active material is ball-milled to obtain powder;

[0057] (2) Mix the powder and water according to 1:0.4 (mass ratio) to make the powder wet;

[0058] (3) Add sulfuric acid with a concentration of 98% to the wet material and mix it. The molar ratio of the powder material to the concentrated sulfuric acid is...

Embodiment 3

[0066] A method of the present invention for leaching valuable metals from waste lithium ion ternary positive electrode materials and preparing the leaching solution into a ternary positive electrode material precursor, the specific steps are as follows:

[0067] (1) Put the waste ternary lithium-ion battery into 120g / L salt water for discharge treatment, disassemble and remove the shell, separate the positive electrode sheet, negative electrode sheet, diaphragm, and electrolyte; then put the positive electrode active material on the positive electrode sheet and the current collector Aluminum foil is separated, and the separated waste lithium-ion battery positive electrode active material is ball-milled to obtain powder;

[0068] (2) Mix the powder and water according to 1:0.6 (mass ratio) to make the powder wet;

[0069] (3) Add sulfuric acid with a concentration of 70% to the wet material and mix, the molar ratio of powder and concentrated sulfuric acid is 1:2, the obtained ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com