Cleaning method for removing oxide layer on surface of silicon material

A technology of surface oxidation and silicon material, which is applied in the direction of using liquid cleaning methods, cleaning methods and utensils, chemical instruments and methods, etc. Printing and other problems, to achieve the effect of low skill requirements, significant cleaning effect, and low acid consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

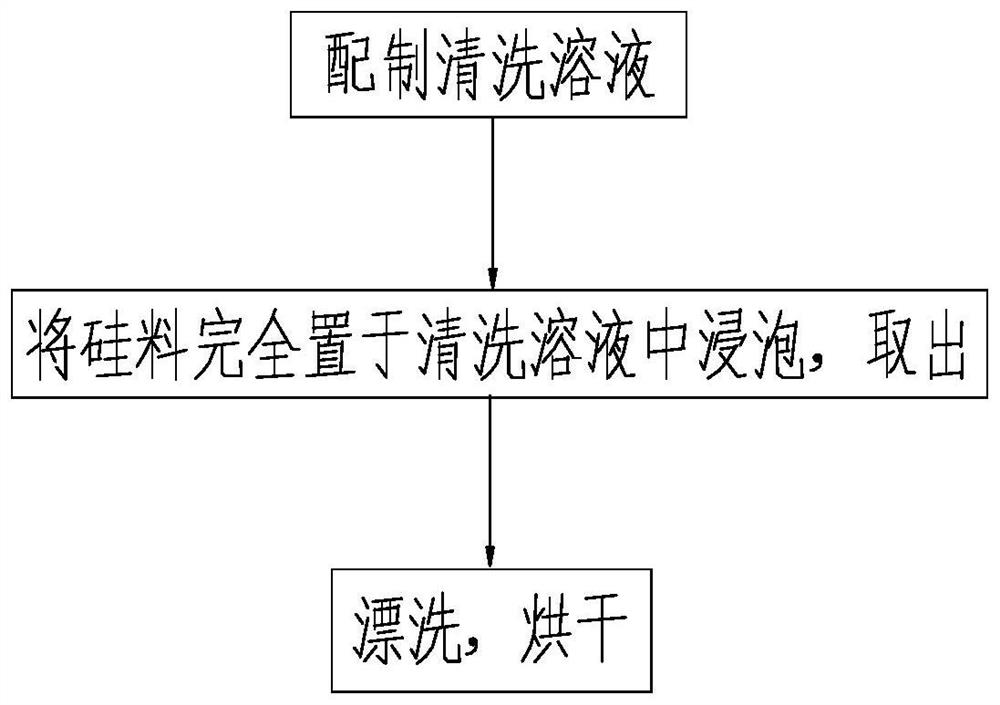

[0037] like figure 1 As shown, a cleaning method for removing an oxide layer on the surface of a silicon material includes the following steps:

[0038] Step S100, preparing a cleaning solution, and stirring it evenly;

[0039] In step S200, the silicon material is completely soaked in the cleaning solution, and taken out;

[0040] Step S300, rinsing and drying.

[0041] In step S100, pure water, methanesulfonic acid, ammonium bifluoride, fluoroboric acid, OP-10, AEO-3, citric acid, and sodium citrate are prepared into a cleaning solution.

[0042] OP-10 has good emulsifying, wetting, leveling, diffusing, washing and other properties, acid, alkali, hard water, OP-10 can be mixed with various surfactants and dyes.

[0043] AEO-3 can be used as solubilizer and water defoamer in other industries, and as the basic raw material for the preparation of surfactant AES. It is also a lipophilic emulsifier. Industry as solubilizer and defoamer component.

[0044] Methanesulfonic aci...

Embodiment 2

[0055] The same parts of this embodiment and the first embodiment will not be repeated, and the differences are:

[0056] Add 300 liters of pure water, 45 kg of methanesulfonic acid, 36 kg of ammonium bifluoride, 1.8 liters of fluoroboric acid, 4.5 kg of OP-10, 1.8 kg of AEO-3, 59.8 kg of citric acid, and 4.5 kg of sodium citrate into a 400L cleaning box , stir evenly, and prepare a cleaning solution. The cost of the cleaning solution is 0.02 yuan / kg, which significantly reduces the cost of the cleaning solution compared to the prior art.

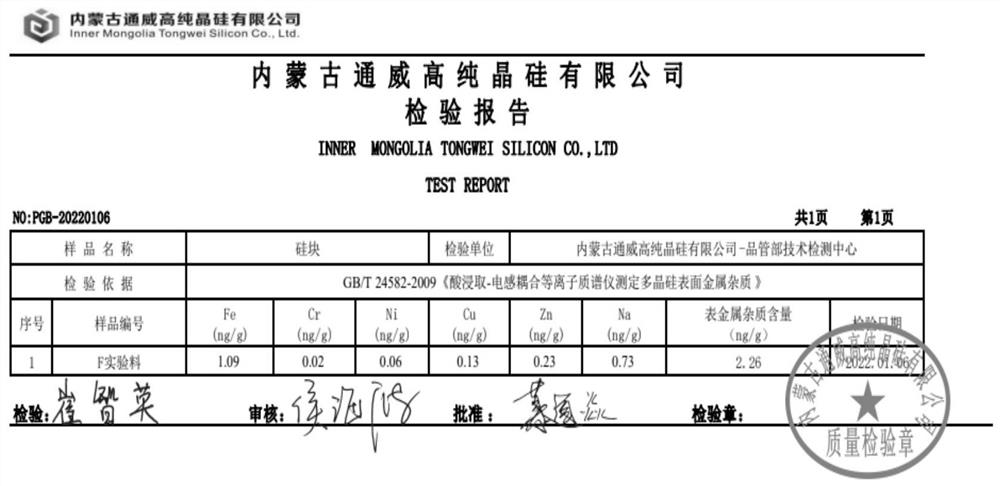

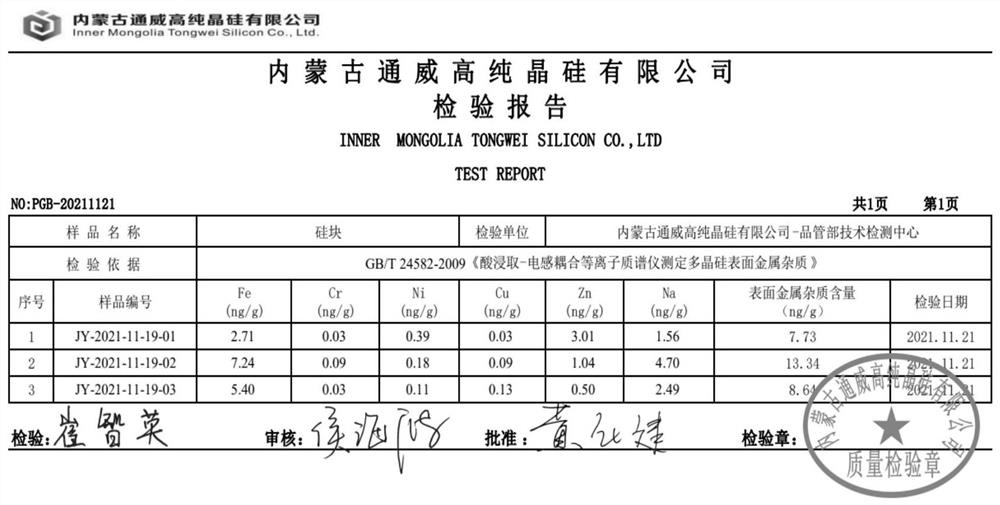

[0057] The cleaning solution was diluted 3 times, the silicon material was completely soaked in the diluted cleaning solution for 30 minutes, taken out, and the metal content on the surface of the silicon material was detected. The results are shown in Figure 2(a). Cleaning operators should dress as required: wear acid-resistant aprons, acid-proof shoes, long-sleeved rubberized gloves, gas masks, and protective face shields.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com