Novel pool-type process for removing alkali of alkaline uranium ore by using hydrochloric acid

A new process technology for uranium ore, which is applied in the new process field of alkali uranium ore pool hydrochloric acid removal, can solve the problems of low recovery rate, low work efficiency, calcium sulfate precipitation and blockage, etc., and achieves reduced acid consumption and simple operation Convenience and the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

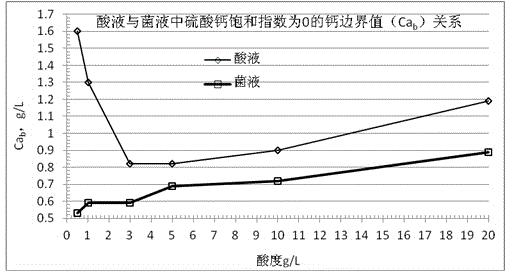

[0083] J2YJ3 hydrochloric acid alkali removal test adopts the working conditions of 10g / L and 7g / L hydrochloric acid leaching solution and the pH control value of the leaching solution is 4. The highest calcium content in the leachate is 24.47-29.79g / L, and the highest calcium content in the leachate with an acidity of 7g / L is 21.81-23.94g / L. It can be seen that the higher the initial acidity of calcium removal, the greater the calcium acidity in the leachate. Immerse the ore with 7g / L and 10g / L hydrochloric acid leaching solutions, and the leaching rate of calcium carbonate based on slag is about 65%. The acid consumption rates of 10g / L and 7g / L leaching solutions with different acidity and ore were 18.2 and 17.5%, respectively. The de-alkali cycle is only 28 days. See Table 10 for the working conditions and test results of the J2YJ3 hydrochloric acid alkali removal test.

[0084] Table 10J2YJ3 hydrochloric acid alkali removal test process conditions and calcium removal ef...

Embodiment 2

[0089] See Table 11 for the working conditions and test results of the J2YJ4-J hydrochloric acid alkali removal test. It can be seen from Table 11 that there is no obvious difference in the alkali removal effect of -5 and -10mm particle size ores. The calcium leaching rate is 36.6%, the average acid consumption rate is 11.2%, the Ca content is 220mg / L at the end of alkali removal, and the test period is 67 days.

[0090] Table 11J2YJ4-J hydrochloric acid alkali removal test process conditions and calcium removal effect

[0091]

[0092]

Embodiment 3

[0094] See Table 12 for the working conditions and test results of the J2YJ6-J hydrochloric acid alkali removal test. It can be seen from Table 12 that there is no obvious difference in the alkali removal effect of -5 and -10mm particle size ores.

[0095] Table 12J2YJ6-Ju hydrochloric acid alkali removal test process conditions and calcium removal effect

[0096]

[0097] The comprehensive results of the above three experiments are shown in Table 13. It can be seen from Table 13 that the liquid meter calcium leaching rate reaches 37-60%, an average of 43.63%; the slag meter calcium leaching rate is 81.8-90.2%, an average of 86%; the average acid consumption rate is 13.39%; the Ca content at the end of alkali removal is 50- 550mg / L, with an average of 242.2mg / L; the test period was 28-78 days, with an average of 61 days.

[0098] Table 13 Comprehensive results of hydrochloric acid alkali removal test

[0099]

[0100]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com