Extraction separation method of rare-earth element

A separation method and rare earth element technology, applied in the field of extraction, can solve problems such as changes in extractant components, influence on system extraction effect, difficulty in back-extraction at equilibrium time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Weigh 112.36 grams of quaternary ammonium chloride 336 and dissolve it in 500 mL of distilled isopropanol to make it completely dissolved; add 6.39 grams of metal sodium to a plastic bottle, add 125 mL of distilled isopropanol, and react at room temperature Prepare sodium alkoxide in 3 hours; mix the above solutions and stir at 50°C for 4 hours to prepare [A336][OR]; centrifuge the resulting solution at 8000 rpm for 10 minutes to remove the sodium chloride precipitate; add to the filtrate 500 ml of deionized water, shaken for 30 minutes, and hydrolyzed to prepare [A336][OH];

[0045] Take 172mL of [A336][OH] solution with a concentration of 0.121mol / L, add 6.2455g of P507 (the molar ratio of [A336][OH] to 507 is 1.1:1), and stir the solution under reflux at 50°C for 12 Hours, after standing the resulting solution for phase separation, the lower phase was discarded, and the upper phase was rotated at 80° C. and 20 mbar to spin out the contained isopropanol and water to o...

Embodiment 2

[0047] Weigh 112.36 grams of quaternary ammonium chloride 336 and dissolve it in 500 mL of distilled isopropanol to make it completely dissolved; add 6.39 grams of metal sodium to a plastic bottle, then add 125 mL of distilled isopropanol, and React for 3 hours to prepare sodium alkoxide; mix the above solutions and stir at 50°C for 4 hours to prepare [A336][OR]; centrifuge the resulting solution at 8000 rpm for 10 minutes to remove the sodium chloride precipitate; add to the filtrate 500 ml of deionized water, shaken for 30 minutes, and hydrolyzed to prepare [A336][OH];

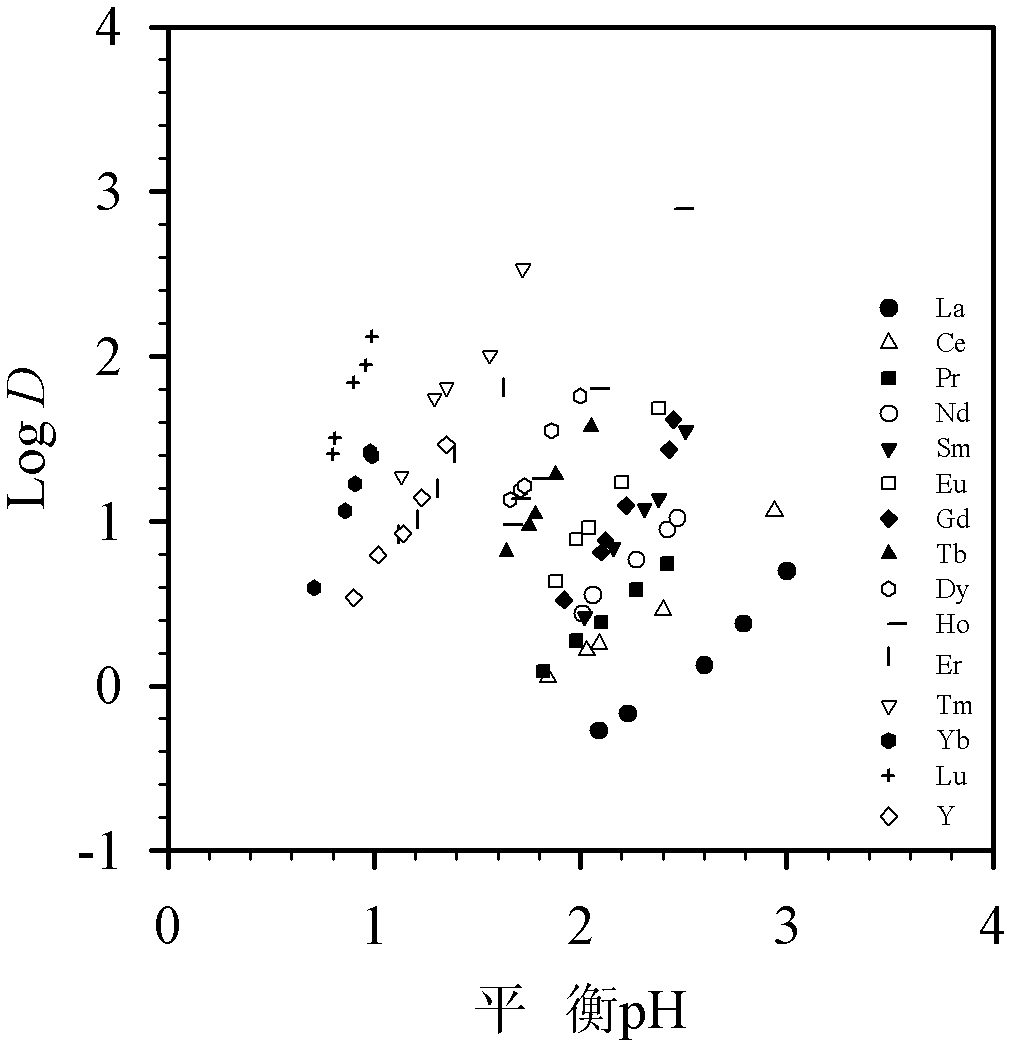

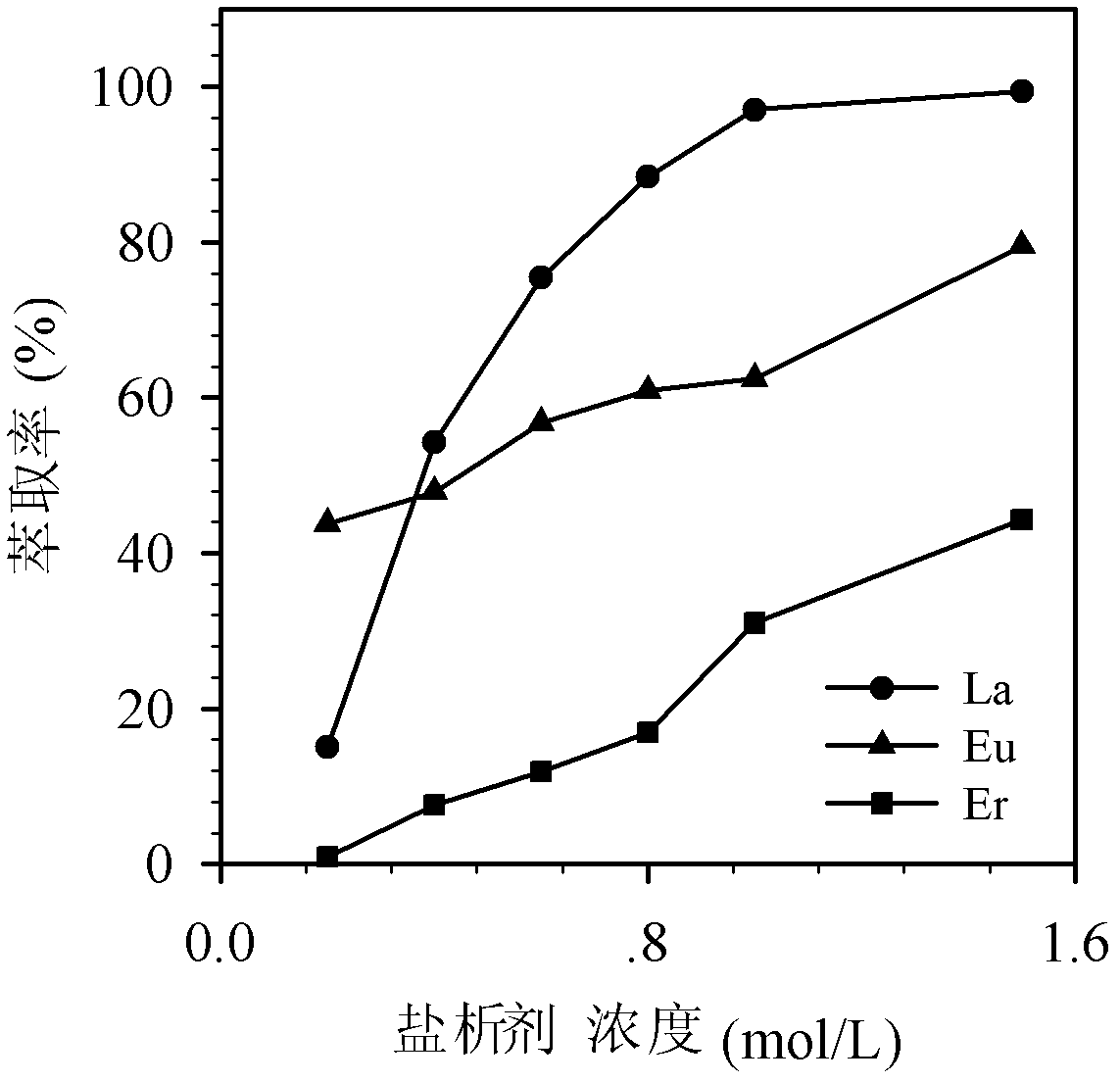

[0048] Take 192 mL of [A336][OH] solution with a concentration of 0.111mol / L, add 8.0057g of P204 (the molar ratio of [A336][OH] to P204 is 1.1:1), and stir the solution under reflux at 50°C for 12 Hours, after standing the resulting solution for phase separation, the lower phase was discarded, and the upper phase was 80° C. and 20 mbar to spin out the contained isopropanol and water to obtain [A336][P204]. ...

Embodiment 3

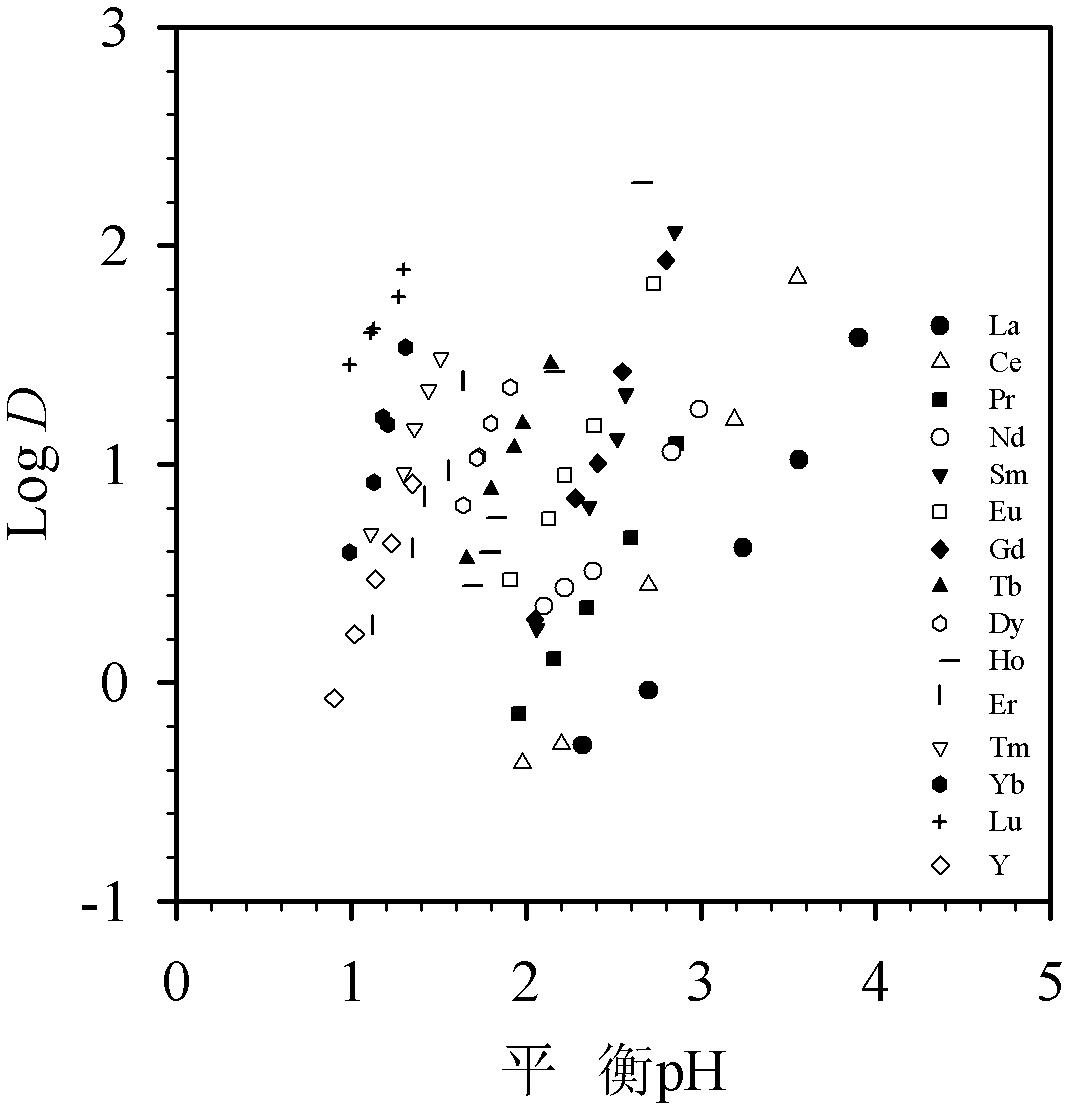

[0049] Example 3[A336][P507] Extraction and separation of a single rare earth ion

[0050] Mix 1.0mL of 0.05mol / L [A336][P507]n-heptane solution with 5.0mL containing NaNO 3 Mix with an aqueous solution of Ho(III), where NaNO in the aqueous solution 3 Concentration is 1.0mol / L, Ho(III) concentration is 7.5×10 -4 mol / L, after shaking at a constant temperature of 25°C for 1 h, measure the concentration of Ho(III) in the water phase, and then calculate the extraction rate and distribution ratio of Ho(III).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com