Method for producing amorphous indium gallium zinc oxide thin film by atomic layer deposition

A technology of indium gallium zinc oxide and atomic layer deposition, which is applied in coating, gaseous chemical plating, metal material coating process, etc., can solve the problem that it is difficult to obtain a large-area surface film with uniform thickness and uniform electrical performance of the device To avoid adverse effects on performance, device performance and reliability, etc., to achieve optimized electrical properties, less defects such as oxygen vacancies, and low deposition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The invention will be described in detail below in conjunction with the accompanying drawings and specific examples. covered with Al 2 o 3 On the monocrystalline silicon substrate of the dielectric film, the IGZO film is grown by atomic layer deposition, and the ratio of the reaction cycles of each oxide is In 2 o 3 : Ga 2 o 3 :ZnO=1:1:1.

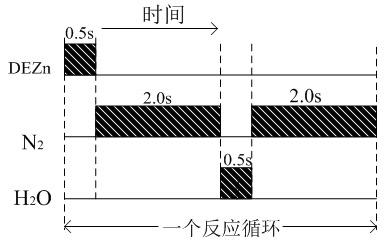

[0030] Step 1, atomic layer deposition growth of ZnO. Using ALD technology to deposit ZnO to grow a reaction cycle, such as figure 1 , where the shaded part indicates that the gas is introduced into the reaction chamber. The reaction source for depositing ZnO is diethyl zinc, the oxidant is water, and the temperature of the reaction chamber is controlled at 100-300°C during the growth process. o C range.

[0031] The specific process of depositing ZnO by ALD technology includes the following steps: (1) Diethyl zinc vapor is passed into the ALD reaction chamber, and the pulse time of the diethyl zinc vapor is 0.5 s. (2) Inj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com