Inorganic/organic composite polyimide-based nanofiber membrane and its preparation method and application

A technology for compounding polyimide-based and nanofiber membranes is applied in the directions of fiber processing, fiber chemical characteristics, single-component synthetic polymer rayon, etc. , good heat resistance, high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

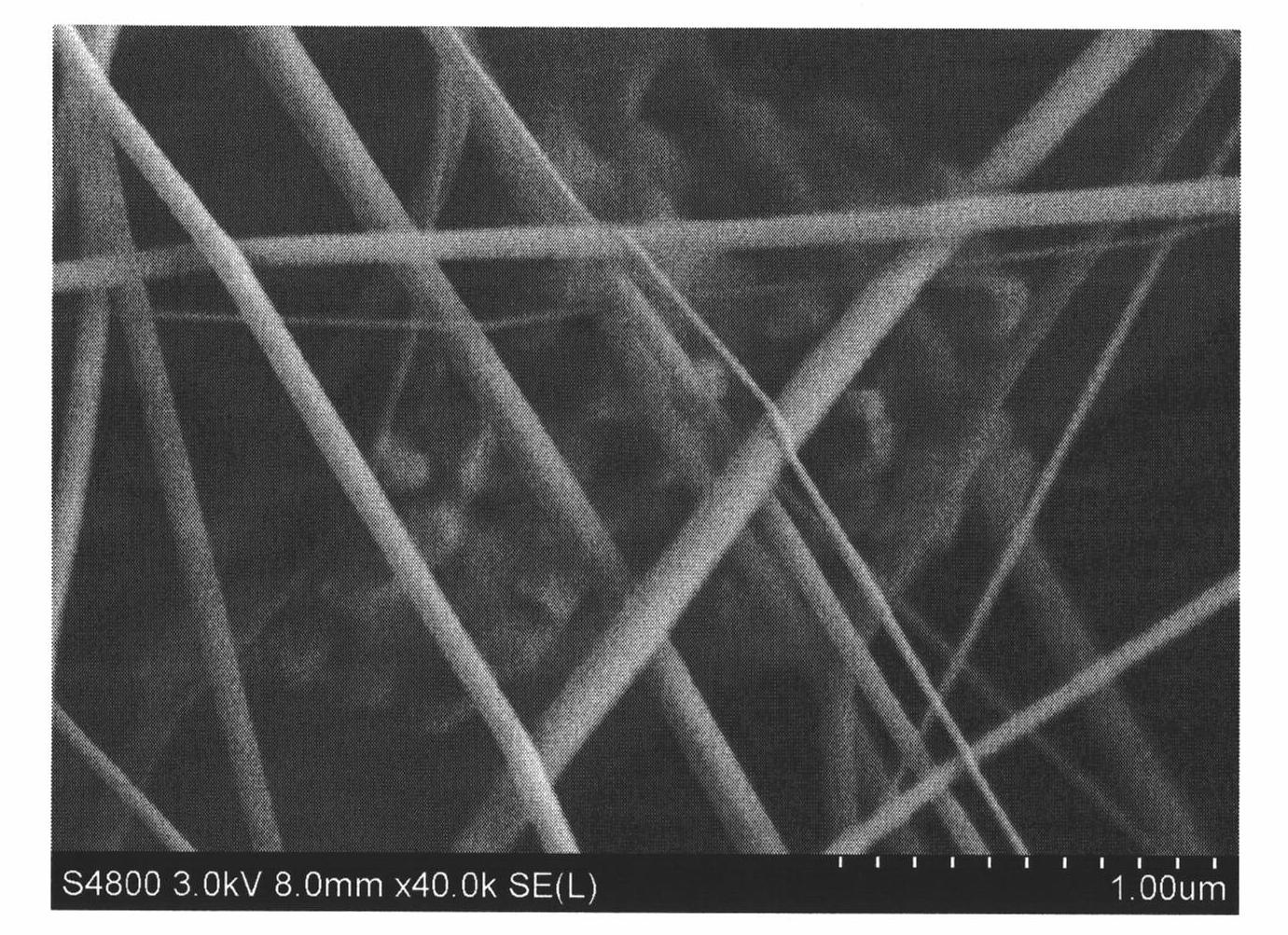

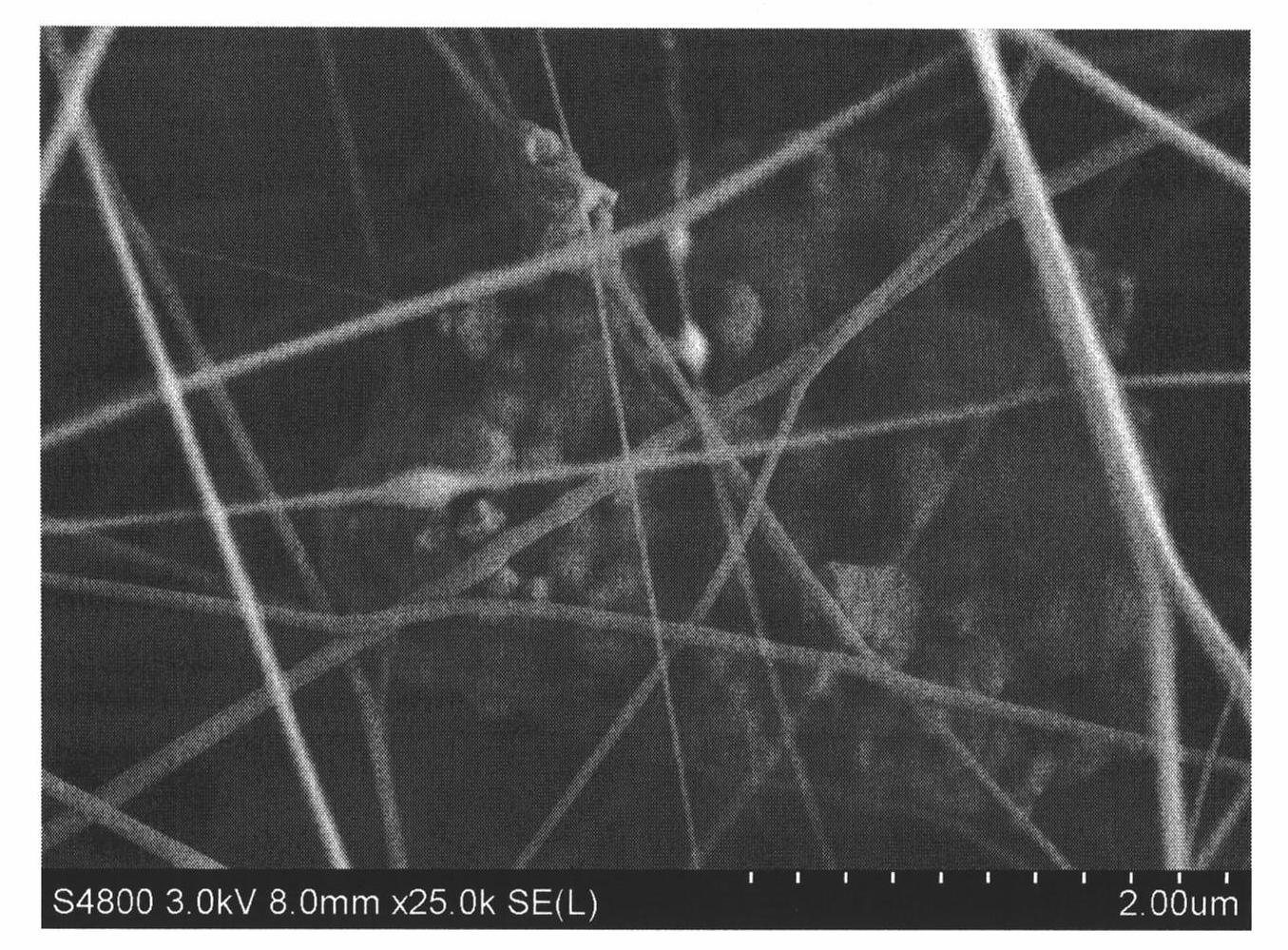

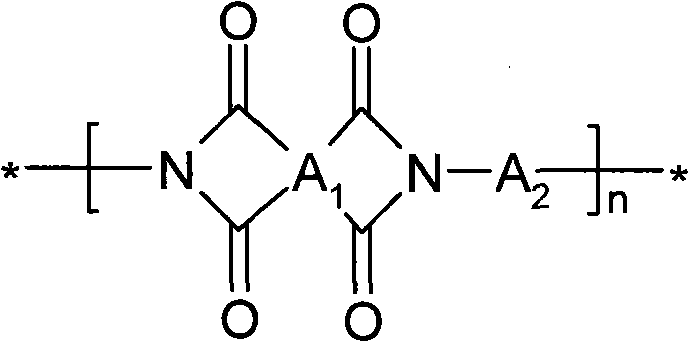

[0035] The preparation method of the present invention is to use electrospinning to nano-spin the polyamic acid hybridized with nano-metal oxides, then use mechanical roller compaction, and finally heat imidize at high temperature to prepare polyimide film .

[0036] The inorganic / organic composite polyimide-based nanofiber membrane of the present invention has excellent chemical stability, high temperature resistance, good permeability and high Tensile Strength. The battery separator obtained in the embodiment of the present invention will not rupture when heated to a high temperature of 350°C; the thermal shrinkage rate of the battery separator at 150°C is less than 0.5%, and the thermal shrinkage rate at 300°C is not greater than 1.5%, which is much smaller than the existing The thermal shrinkage rate of 3% and 5% in the technology, the puncture strength is greater than the puncture strength of the battery separator in the prior art, the surface and internal pores of the m...

Embodiment 1

[0054] Add 4.36 grams of pyromellitic dianhydride, 4.00 grams of diaminodiphenyl ether, and 45.5 milliliters of N,N-dimethylacetamide into a 150 milliliter four-neck flask, and then stir the reaction in an ice bath at 0-5°C , the reaction time was 24 hours to obtain a uniform polyamic acid solution (15% by mass fraction). After the reaction, the polyamic acid solution was stored in a refrigerator at 4°C. Take out 1.6667 g of polyamic acid solution in a 50 ml volumetric flask, add N,N-dimethylacetamide to make it volume to 50 ml, prepare a solution of 0.0050 g / ml, and use an Ubbelohde viscometer in a water bath at 30°C Its intrinsic viscosity was determined to be 2.11dL / g. Another 1.0 milliliter of polyamic acid solution was taken out, and 7.5 milligrams of nano-zirconia (accounting for 5% of the mass fraction of polyamic acid) was slowly added under the condition of stirring until the dispersion was even, and then vacuum degassed and then electrospun, the needle The diameter...

Embodiment 2

[0056] Add 5.88 grams of biphenyltetracarboxylic dianhydride, 4.97 grams of diphenylsulfone diamine, and 60.3 milliliters of N,N-dimethylacetamide into a 150 milliliter four-neck flask, and then stir the reaction in an ice bath at 0-5°C , the reaction time was 24 hours to obtain a uniform polyamic acid solution (15% by mass fraction). After the reaction, the polyamic acid solution was stored in a refrigerator at 4°C. Take out 1.6667 g of polyamic acid solution in a 50 ml volumetric flask, add N, N-methylacetamide to make the volume to 50 ml, prepare a solution of 0.0050 g / ml, and measure it in a water bath at 30°C with an Ubbelohde viscometer Its intrinsic viscosity is 1.89dL / g. Another 1.0 milliliter of polyamic acid solution was taken out, and 7.5 milligrams of nano-silica (accounting for 5% of the mass fraction of polyamic acid) was slowly added under the condition of stirring until uniform dispersion, and then vacuum degassed and then electrospun, The diameter of the nee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com