Preparation method and application of super-hydrophobic membrane

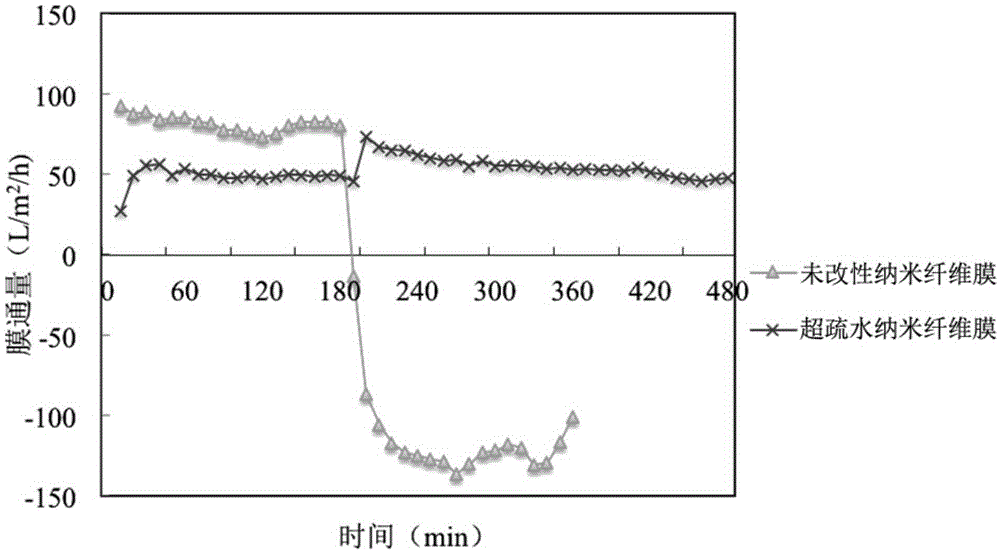

A super-hydrophobic and hydrophobic technology, applied in the field of membrane separation technology and water treatment, can solve the problems of poor anti-pollution performance and poor anti-wetting, and achieve the effect of promoting large-scale industrial application, small heat loss and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present embodiment provides a kind of preparation method of superhydrophobic membrane, comprises the following steps:

[0026] (1) Prepare 12wt% PVDF electrospinning solution, the solvent is N,N-dimethylacetamide and acetone with a mass ratio of 4:1, add 0.5wt% metal-organic framework nanoparticles, and spin the spinning solution at 45 After stirring for 2 hours at ℃, let stand for defoaming for 2 hours;

[0027] (2) Electrospinning parameters are selected: the voltage is 12kv, the inner diameter of the needle is 0.6mm, the injection speed of the spinning solution is 0.05mm / min, the distance between the receiving drum and the spinneret is 22cm, and the rotating speed of the receiving drum is 50r / min. The silk ambient temperature is 30° C., the air relative humidity is 50%, and the electrospinning process is carried out for 20 hours. Place the obtained nanofiber membrane between two glass plates, and put it into a 170°C oven for 30min heat treatment;

[0028] (3) T...

Embodiment 2

[0032] The present embodiment provides a kind of preparation method of superhydrophobic membrane, comprises the following steps:

[0033] (1) Prepare 15wt% PVDF electrospinning solution, the solvent is N,N-dimethylacetamide and acetone (mass ratio is 4:1), add 0.5wt% metal-organic framework nanoparticles, and spin the spinning solution in After stirring for 2 hours at 45°C, let it stand for 2 hours for defoaming;

[0034] (2) Electrospinning parameters are selected: the voltage is 10kv, the inner diameter of the needle is 0.6mm, the injection speed of the spinning solution is 0.2mm / min, the distance between the receiving drum and the spinneret is 17cm, the rotating speed of the receiving drum is 5r / min, and spinning The silk ambient temperature is 30° C., the air relative humidity is 50%, and the electrospinning process is carried out for 5 hours. Place the obtained nanofiber membrane between two glass plates, and put it into a 170°C oven for 1h heat treatment;

[0035] (3) ...

Embodiment 3

[0039] The present embodiment provides a kind of preparation method of superhydrophobic membrane, comprises the following steps:

[0040] (1) Prepare 12wt% PVDF electrospinning solution, the solvent is N,N-dimethylacetamide and acetone (mass ratio is 4:1), add 4wt% zinc oxide nanoparticles, and spin the spinning solution at 45°C After stirring for 2 hours, let stand for defoaming for 2 hours;

[0041] (2) Electrospinning parameters are selected: the voltage is 12kv, the inner diameter of the needle is 0.6mm, the injection speed of the spinning solution is 0.2mm / min, the distance between the receiving drum and the spinneret is 22cm, and the rotating speed of the receiving drum is 100r / min. The silk ambient temperature is 30° C., the air relative humidity is 50%, and the electrospinning process is carried out for 5 hours. Place the obtained nanofiber membrane between two glass plates, and put it into a 170°C oven for 30min heat treatment;

[0042] (3) The molar ratio is titani...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roll angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com