Nano copolymer fibrous membrane material capable of being biodegraded and absorbed and preparation process and use thereof

A nanofiber membrane and biodegradation technology, applied in the field of gelatin-based nanofiber membrane material and its preparation, can solve the problems of thick diameter, expensive solvent, and restrictions on the wide application of gelatin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

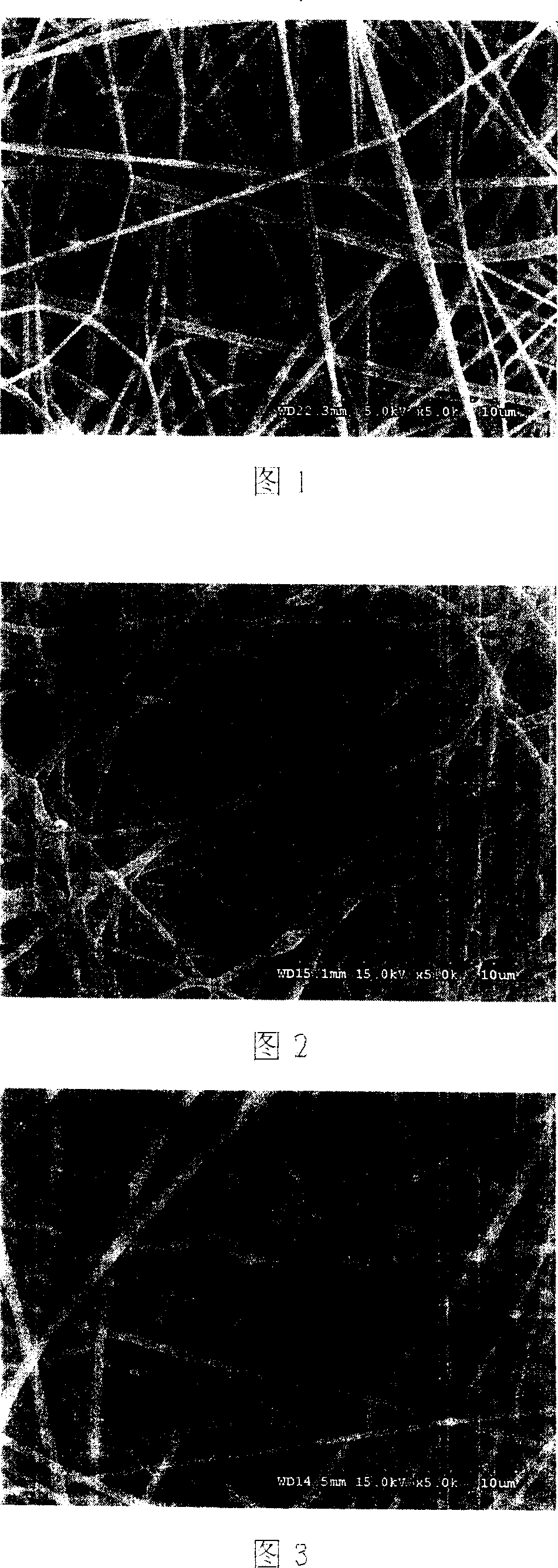

Embodiment 1

[0044] 1) Prepare 50ml of water / ethanol solution of gelatin with a mass volume concentration of 15w / v%, wherein the gelatin is medicinal gelatin with a molecular weight of 80,000, and the volume ratio of water / ethanol is 90:10, and put in the solution device;

[0045] 2) The spinneret is fixed, the metal plate is used as the collector, and the collector moves in the horizontal direction with a moving speed of 0.3m / s and a moving range of 10cm;

[0046] 3) Adjust the distance between the spinneret and the collecting plate to be 15cm;

[0047] 4) The ambient temperature of spinning is 45 degrees, including the temperature of the solution in the liquid storage device and the temperature of the collecting plate are both 40 degrees, and the air flow rate in the environment is controlled at 0.5-0.8m 3 / hr;

[0048] 5) Turn on the high-voltage power supply, adjust the voltage to 22KV, and the feeding speed of the solution is 60ul / min to perform spinning. The average fiber diameter ...

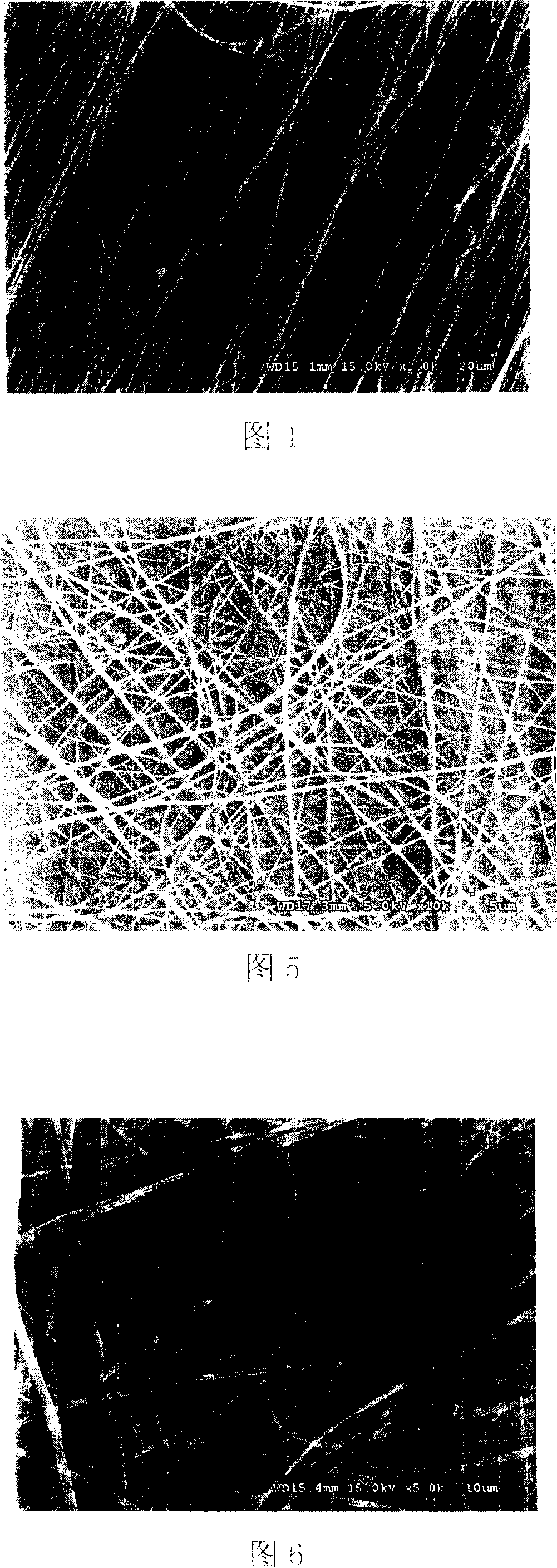

Embodiment 2

[0051] 1) Prepare 20ml of water / ethanol solution of gelatin / hyaluronic acid with a gelatin concentration of 4.5w / v%, wherein the mass ratio of gelatin / hyaluronic acid is 4:1, and the volume ratio of water / ethanol is 90:10. The substance solution is placed in the liquid storage device;

[0052] 2) The spinneret moves horizontally at a speed of 0.5m / min. The metal plate acts as a collector, and the collector moves horizontally at a moving speed of 1m / min and a moving range of 10cm;

[0053] 3) Adjust the distance between the spinneret and the collecting plate to be 20cm;

[0054] 4) The ambient temperature of spinning is 45 degrees, including the temperature of the solution in the liquid storage device and the temperature of the collecting plate are 45 degrees, and the air flow speed in the environment is 1m 3 / hr;

[0055] 5) Turn on the high-voltage power supply, adjust the voltage to 25KV, and the feeding speed of the solution is 100ul / min, and perform spinning, and the obt...

Embodiment 3

[0058] 1) Prepare 100ml of water / ethanol solution of gelatin with a mass volume concentration of 10w / v%, wherein the volume ratio of water / ethanol is 90:10, add 2 mg of nano-silver to the gelatin aqueous solution, mix well and place in the stock solution device;

[0059]2) The metal copper mesh is used as a collector, and the spinneret and receiver are fixed;

[0060] 3) Adjust the distance between the spinneret and the collecting plate to be 15cm;

[0061] 4) The ambient temperature of spinning is 45 degrees, including the temperature of the solution in the liquid storage device and the temperature of the collecting plate are 45 degrees, and the air flow rate in the environment is 2m 3 / hr;

[0062] 5) Turn on the high-voltage power supply, adjust the voltage to 25KV, the feeding speed of the solution is 80ul / min, and perform spinning, and the obtained fiber film is vacuum-dried at 40 degrees for 2 days; the average diameter of the fiber is 300nm, and the film thickness is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com