Abrasion and cut resistant coating and coated glove

a technology of abrasion and cut resistance and coating, applied in the field of coatings and gloves, can solve the problems of affecting the use of gloves, affecting the durability of gloves, and many gloves manufactured with latex or thermoplastic elastomers are expensive to manufacture and are not durable, and none provide a flexible, durable glove with foam coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

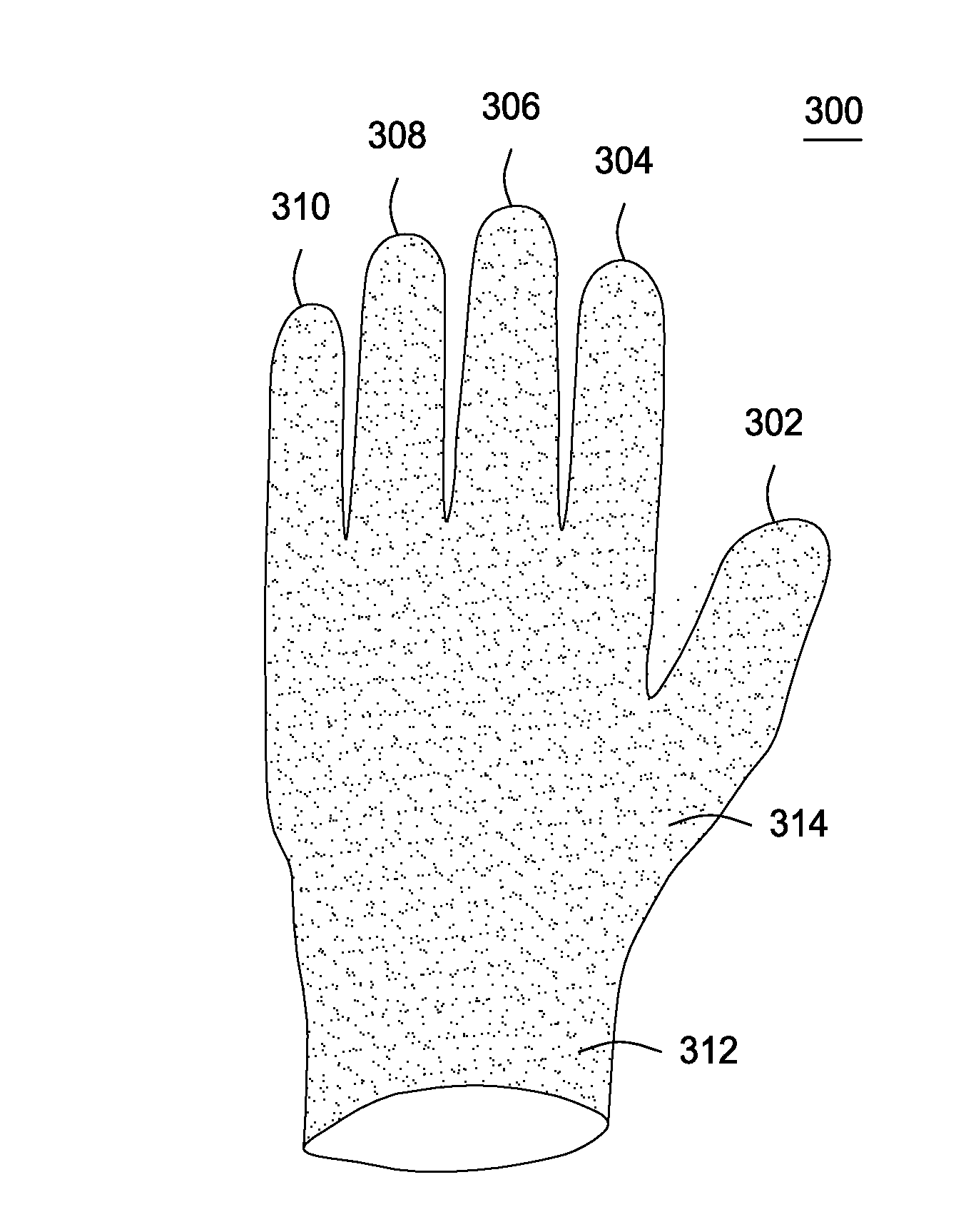

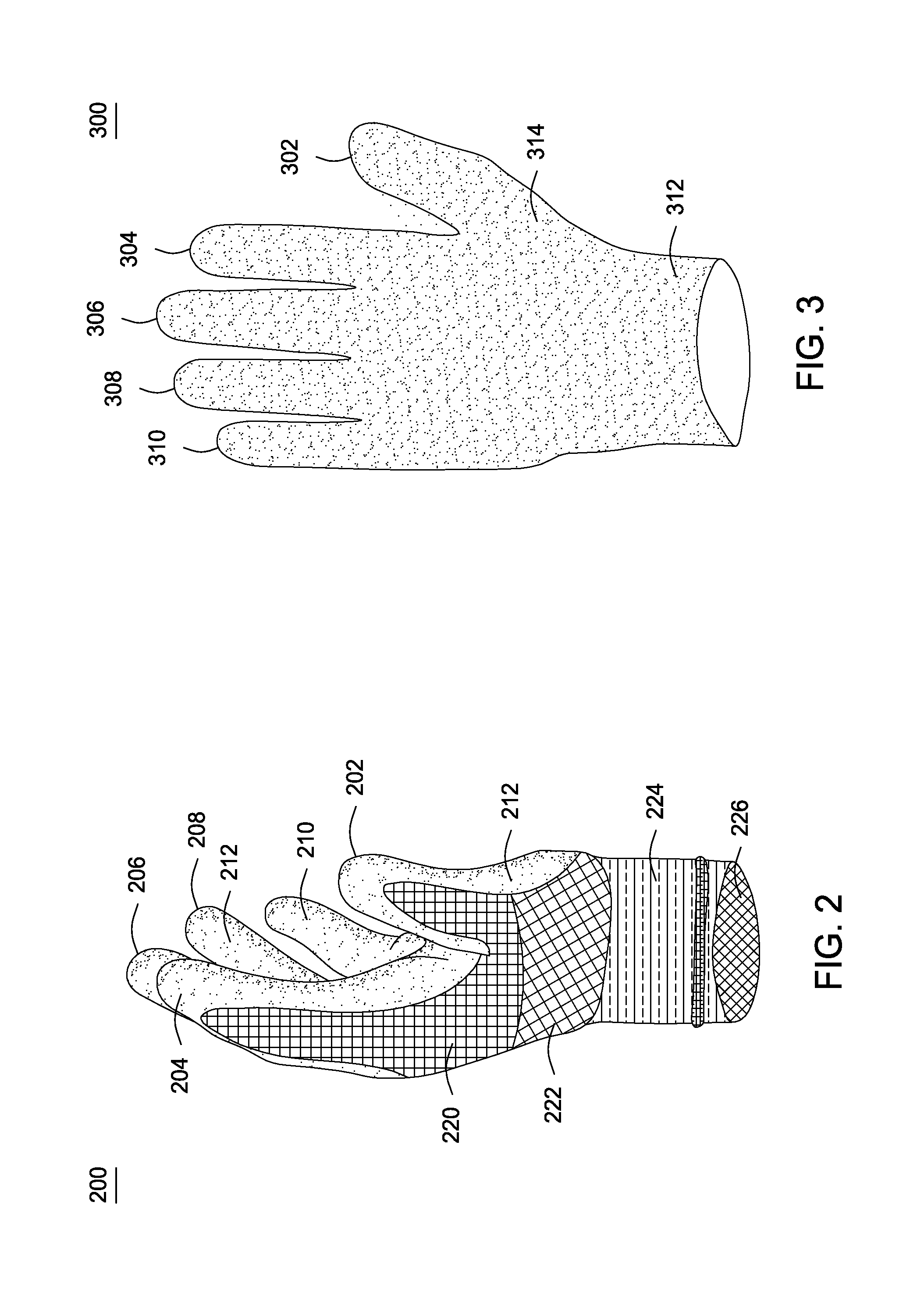

Image

Examples

Embodiment Construction

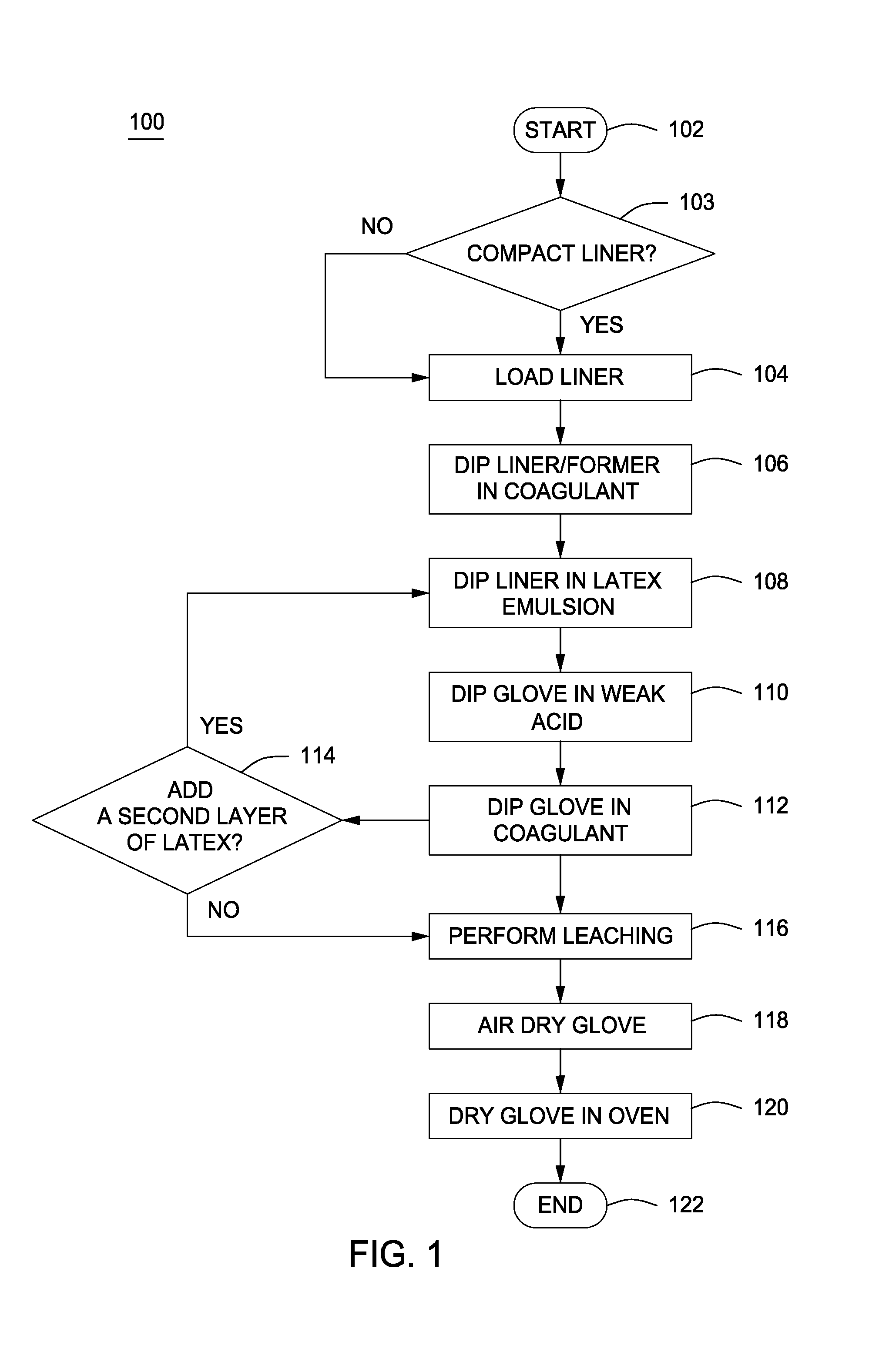

[0010]Embodiments of the present invention comprise coatings and gloves and methods for making durable coatings and gloves having improved physical properties, and especially abrasion- and cut-resistance properties, while maintaining a very thin and flexible glove for improved dexterity during use. Gloves disclosed herein have vastly improved abrasion resistance, as measured by Taber and Martindale abraders and test protocols, as well as increased cut resistance. For example, latex, polymeric, or elastomeric coatings, as well as coated gloves, made in accordance with embodiments of the invention, are capable of attaining EN level 4 abrasion resistance, while, heretofore, no coating or glove having a thin, flexible elastomeric, polymeric, or latex layer is known to have attained performance beyond EN level 3. Also, gloves in accordance with embodiments of the invention have attained an EN level 2 cut resistance where previous gloves achieved only a cut resistance of EN level 1.

[0011]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com