Preparation and application of organic silicon polymer super-hydrophobic textile finishing agent

A fabric finishing agent and super-hydrophobic technology, applied in fiber processing, plant fibers, animal fibers, etc., can solve problems such as affecting the strength and appearance of fabrics, restricting the practical application of super-hydrophobic fabrics, and complex processes, and achieve the convenience of large-scale production, The effect of low cost and simplified preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

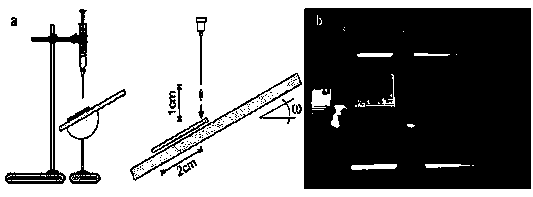

[0036] (1) Preparation of superhydrophobic fabric finishing agent: take 0.6mL phenyltriethoxysilane, 0.2mL tetraethoxysilane and 0.1mL 3-(2,3-glycidoxy)propyltrimethoxysilane , Added to 50mL ethanol-water solution (ethanol / water=7:1v / v), magnetically stirred for 10min to obtain a uniform solution; then add 0.2mL ammonia and 1mL polyphenyl silicone resin, react at 50℃ for 24h; cool to room temperature , Adjust the pH to neutral with 1M hydrochloric acid to obtain a superhydrophobic fabric finishing agent.

[0037] (2) Preparation of super-hydrophobic fabric: Measure 10 mL of fabric finishing agent, dilute 5 times with ethanol, magnetically stir for 5 minutes, and ultrasonically disperse for 5 minutes. Then the 10cm×10cm polyester fabric is immersed in it, 0.3% acetic acid is added, and it is allowed to stand and soak for 5 minutes, and then the fabric is treated at 120°C for 8 minutes to obtain a superhydrophobic fabric.

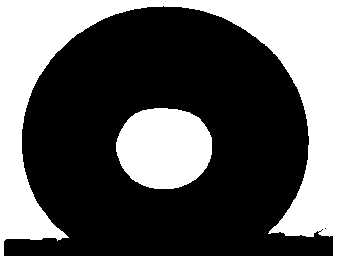

[0038] Evaluation of superhydrophobicity and stability of s...

Embodiment 2

[0040] (1) Preparation of superhydrophobic fabric finishing agent: take 8mL hexadecyltriethoxysilane, 2mL ethyltriethoxysilane and 5mL 3-(2,3-glycidoxy)propyltrimethoxy Silane was added to 400mL ethanol / isopropanol-water solution (ethanol / isopropanol / water=6:3:1v / v / v), magnetically stirred for 5min to obtain a uniform solution; then added 2mL ethylenediamine, 8mL poly Dimethyl dimethoxy silicone resin and 2 mL polymethyl vinyl silicone resin were reacted at 25° C. for 36 hours; the pH was adjusted to neutral with 1M hydrochloric acid to obtain a superhydrophobic fabric finishing agent.

[0041] (2) Preparation of super-hydrophobic fabric: Measure 100 mL of fabric finishing agent, dilute it with ethanol to 8 times its volume, magnetically stir for 5 min, and ultrasonically disperse for 5 min. Then immerse a 50cm×50cm cotton fabric in it, add 0.1% acetic acid, leave it to soak for 3 minutes, and then treat the fabric at 160°C for 3 minutes to obtain a superhydrophobic fabric.

[004...

Embodiment 3

[0044] (1) Preparation of superhydrophobic fabric finishing agent: add 20mL methyltriethoxysilane, 5 methyl potassium silicate and 12mL aminopropyltrimethoxysilane to 1L ethanol / ethylene glycol-water solution (ethanol / Glycol / water=2:2:1v / v / v), mechanically stir for 5min to obtain a uniform solution; then add 10mL 1M sodium hydroxide aqueous solution and 8mL polydimethyldimethoxysilicone resin, at 40℃ React for 12h; adjust the pH to neutral with 1M hydrochloric acid to obtain a superhydrophobic fabric finishing agent.

[0045] (2) Preparation of super-hydrophobic fabric: Measure 500mL of fabric finishing agent, dilute it with ethanol / water solution (ethanol / water=1:1v / v) 10 times, mechanically stir for 5min, and ultrasonically disperse for 5min. Then, immerse 50cm×50cm wool and silk, add 0.1% acetic acid, leave to soak for 4 minutes, and then treat the fabric at 80°C for 4 minutes to obtain a superhydrophobic fabric.

[0046] Evaluation of superhydrophobicity and stability of supe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com