Antibiotic textile and production method thereof

A technology of antibacterial textiles and textiles, applied in textiles and papermaking, wear-resistant fibers, plant fibers, etc., can solve the problems of antibacterial textiles such as poor washability, poor antibacterial durability, and long production cycle, and achieve excellent antibacterial properties and washability Good performance and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The present invention also provides a kind of preparation method of antibacterial textile of the present invention, comprising:

[0068] Antibacterial textiles were obtained by depositing nanosilver on titanium dioxide-loaded textiles,

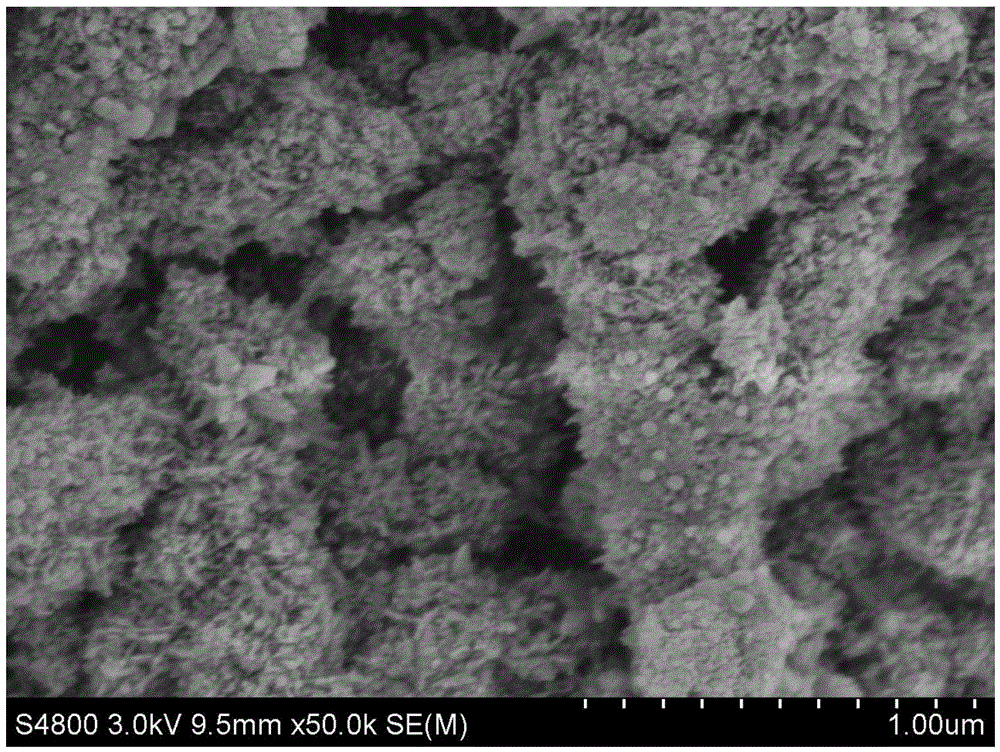

[0069] Wherein, the morphology of the titanium dioxide in the titanium dioxide-loaded textile is a flower shape.

[0070] According to the present invention, nano-silver is deposited on the textiles loaded with titanium dioxide to obtain antibacterial textiles, wherein the textiles loaded with titanium dioxide are preferably prepared according to the following method:

[0071] The titanium potassium oxalate, water and diethylene glycol are mixed, and then added into textiles for mixed reaction to obtain the textiles loaded with titanium dioxide.

[0072] According to the present invention, the present invention mixes titanium potassium oxalate, water and diethylene glycol, and then adds textiles for mixed reaction to obtain titanium di...

Embodiment 1

[0096]Dissolve 2mmol of potassium titanium oxalate in 15mL aqueous solution and ultrasonically disperse evenly, then add 20mL diethylene glycol solution to the dispersion, stir evenly under the action of a magnetic rotor, and put the above prepared solution in a hydrothermal reaction kettle , put the cleaned cotton fabric into the hydrothermal reaction kettle and put it into the oven for reaction. The reaction temperature is 150°C and the reaction time is 1h. TiO 2 Fabric surface, that is, textiles loaded with titanium dioxide;

[0097] Soak the titanium dioxide-loaded textiles obtained above in the prepared 0.5M silver ammonia solution for 30 minutes in the dark, then rinse them with water; Rinse with deionized water and dry to obtain antibacterial textiles.

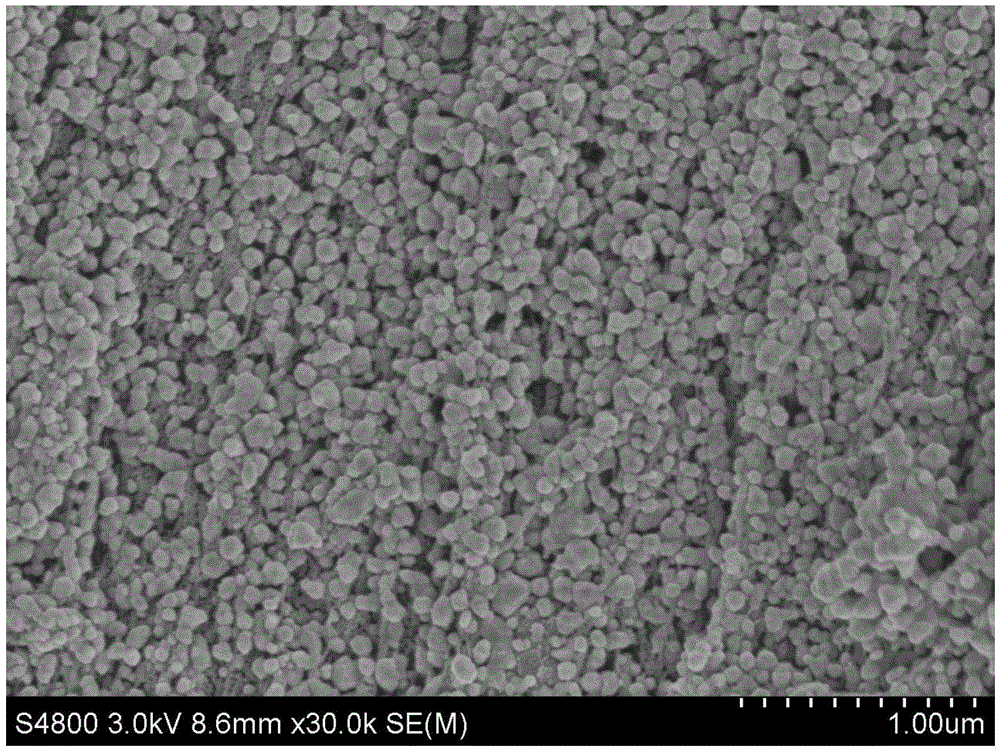

[0098] The appearance of the obtained antibacterial textile is detected, and the results are shown in figure 1 , figure 1 It is the SEM image of the antibacterial textile prepared in Example 1 of the present inventi...

Embodiment 2

[0100] Dissolve 2mmol of potassium titanium oxalate in 15mL aqueous solution and ultrasonically disperse evenly, then add 20mL diethylene glycol solution to the dispersion, stir evenly under the action of a magnetic rotor, and put the above prepared solution in a hydrothermal reaction kettle , put the cleaned cotton fabric into the hydrothermal reaction kettle and put it into the oven to react. The reaction temperature is 150°C and the reaction time is 5h. TiO 2 Fabric surface, that is, textiles loaded with titanium dioxide;

[0101] Soak the titanium dioxide-loaded textiles obtained above in the prepared 0.3M silver-ammonia solution to avoid light for 30 minutes, and then rinse them with clean water; then put them into 0.3M glucose solution and soak them in the dark for 30 minutes. Rinse with deionized water and dry. Get Antibacterial Textiles.

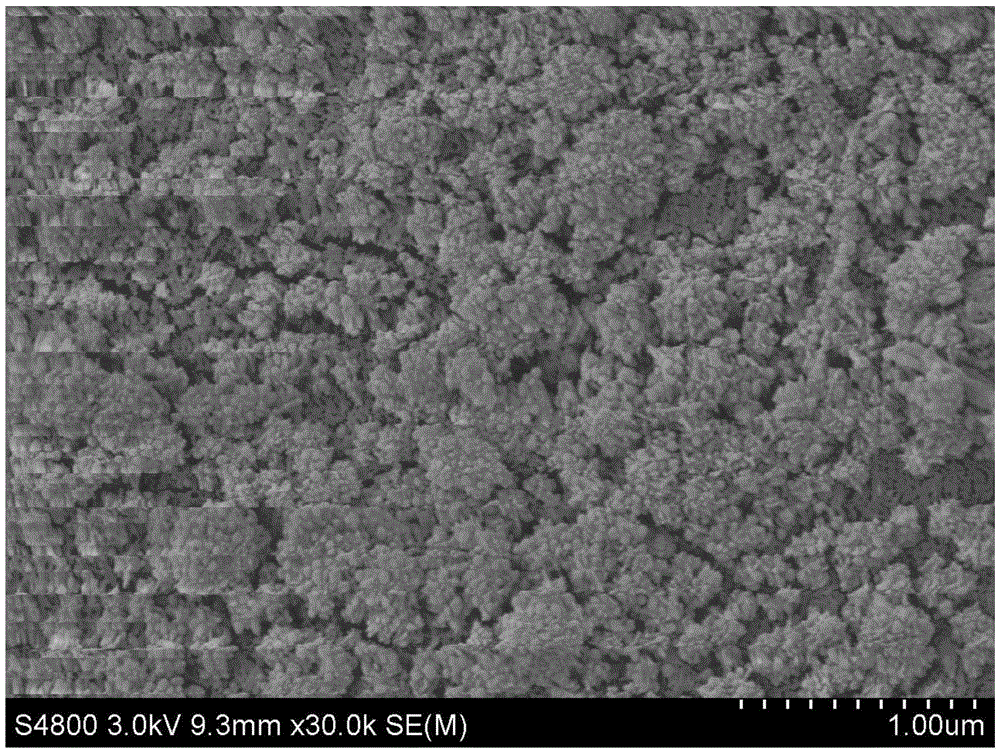

[0102] The appearance of the obtained antibacterial textile is detected, and the results are shown in figure 2 , figure 2 It...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com