Silicone modified weak zwitterionic polyurethane emulsion and preparation method thereof

A technology of polyurethane emulsion and zwitterion, which is applied in the direction of improved hand-feeling fibers, wear-resistant fibers, textiles and papermaking, and can solve problems such as poor compatibility and compatibility, low stability, and large particle size of the emulsion, and achieve Easy to disperse and emulsify, good emulsion stability, good film elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

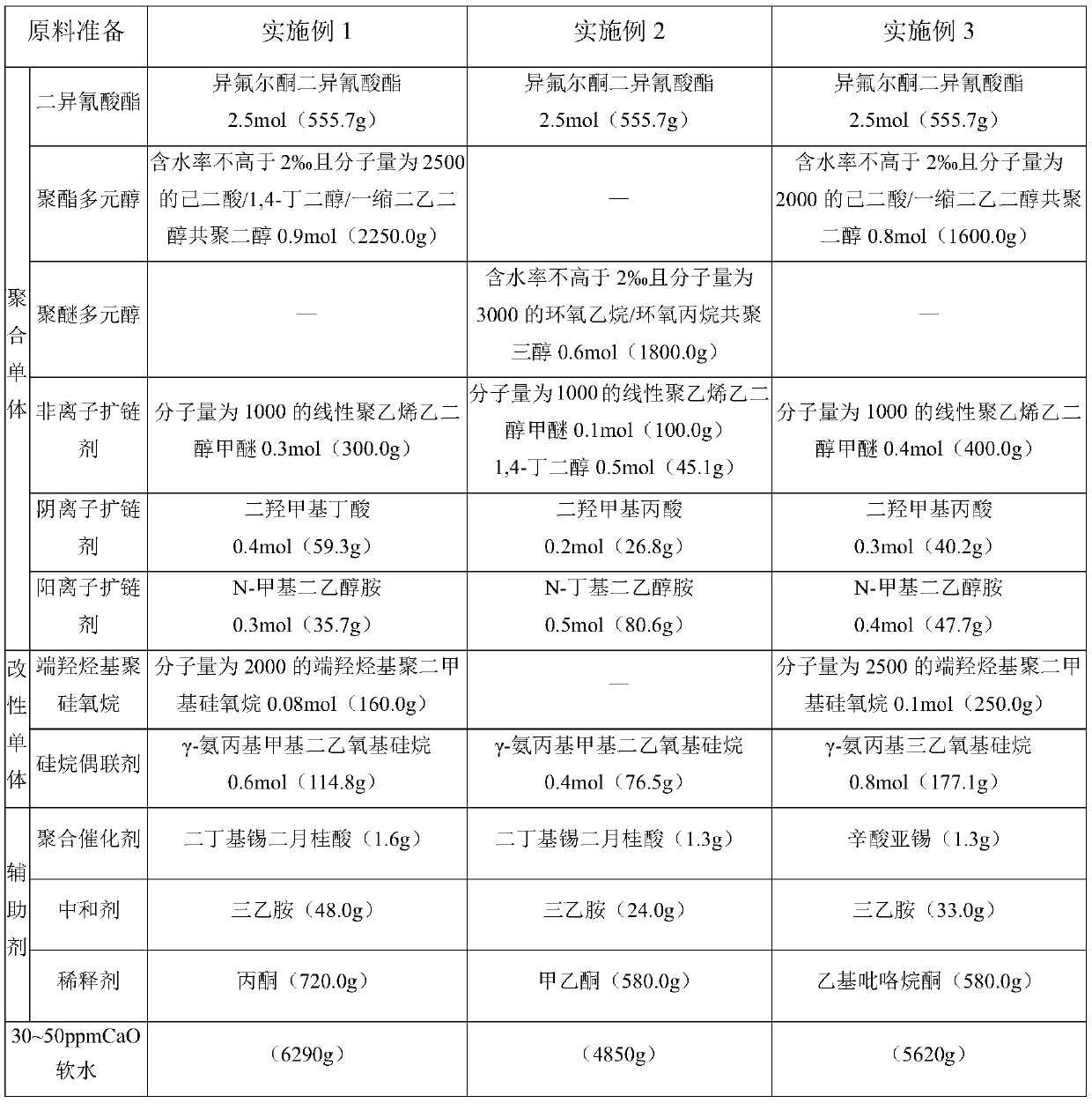

Examples

preparation example Construction

[0066] The preparation method of the silicone-modified weak zwitterionic polyurethane emulsion of the present invention comprises the following steps:

[0067] (1) Prepolymerization: Prepolymerize diisocyanate with polyester polyol and / or polyether polyol, polymerization catalyst and optional hydroxyl-terminated polysiloxane to prepare a weakly zwitterionic polyurethane prepolymer;

[0068] (2) Chain extension: reacting the weak zwitterionic polyurethane prepolymer with a nonionic chain extender, an anionic chain extender, and some diluents to prepare a weak zwitterionic polyurethane intermediate;

[0069] (3) Capping: reacting the weak zwitterionic polyurethane intermediate with a silane coupling agent to obtain a silicone-modified weak zwitterionic polyurethane polymer;

[0070] (4) Emulsification: Mix and emulsify the silicone-modified weakly zwitterionic polyurethane polymer, neutralizer, remaining diluent, cationic chain extender, and water to prepare silicone-modified we...

Embodiment 1

[0117] (1) Prepolymerization

[0118] (1.1) Put polyester polyol and hydroxyl-terminated polysiloxane into the reactor and heat up to 75°C;

[0119] (1.2) Put in diisocyanate and keep stirring, control the temperature of the reaction system to 80°C, and react for 20 minutes;

[0120] (1.3) Maintain the temperature of the reaction system at 80°C, and put in the polymerization catalyst at a constant speed within 15 minutes;

[0121] (1.4) Raise the temperature and control the temperature of the reaction system to 92° C., and keep it warm for 90 minutes to prepare a silicone-modified weakly zwitterionic polyurethane prepolymer.

[0122] (2) Chain extension

[0123] (2.1) cooling the reaction system in step (1.4) to 85°C;

[0124] (2.2) Evenly add non-ionic chain extenders and anionic chain extenders within 20 minutes, and maintain the temperature at 85°C;

[0125] (2.3) Control the reaction temperature to 85°C and continue to stir the reaction for 170min. During this period, ...

Embodiment 2

[0138] (1) Prepolymerization

[0139] (1.1) Put the polyether polyol into the reactor and heat up to 80°C;

[0140] (1.2) Put in diisocyanate and keep stirring, control the temperature of the reaction system to 85°C, and react for 20 minutes;

[0141] (1.3) Maintain the temperature of the reaction system at 85°C, and put in the polymerization catalyst at a constant speed within 20 minutes;

[0142] (1.4) Raise the temperature and control the temperature of the reaction system to 89° C., and keep the temperature for 100 minutes to prepare a weakly zwitterionic polyurethane prepolymer.

[0143] (2) Chain extension

[0144] (2.1) cooling the reaction system in step (1.4) to 80°C;

[0145] (2.2) Evenly add non-ionic chain extender and anionic chain extender within 30 minutes, and maintain the temperature at 80°C;

[0146] (2.3) Control the reaction temperature to 80° C. and continue stirring for 150 minutes. During this period, add diluent not exceeding 80% of the total amount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com