Preparation method of graphene-butadiene-acrylonitrile latex frosted gloves

A technology of nitrile rubber and graphene, which is applied in the direction of gloves, wear-resistant fibers, improved hand-feeling fibers, etc., to achieve the effect of good elasticity, strong wear resistance, and soft hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present embodiment relates to a kind of preparation method of graphene-nitrile latex scrub gloves, and described preparation method comprises the steps:

[0042] Step 1, preparing ball abrasive, thickening slurry and graphene-nitrile latex frosting composite slurry.

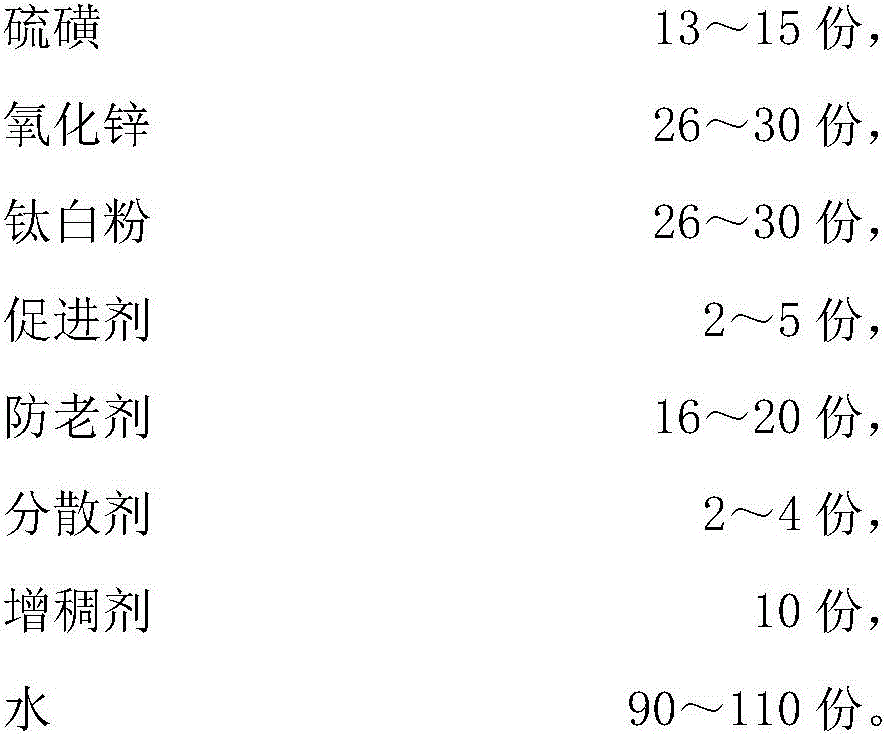

[0043] The preparation of ball mill: described ball mill comprises each component of following parts by weight:

[0044]

[0045] The preparation of thickening slurry: described thickening slurry comprises each component of following parts by weight:

[0046] Sodium carboxymethyl cellulose 4.5 parts,

[0047] 10 parts of water,

[0048] 0.4 parts of 10wt% KOH;

[0049] When preparing, add the sodium carboxymethyl cellulose into water, stir evenly, then add the KOH, stir and place before use.

[0050] The preparation of graphene-nitrile latex frosted composite slurry: 10wt% KOH 1.5 weight parts and water 7.5 weight parts are mixed well, under stirring state slowly add in nitrile rubber (solid con...

Embodiment 2

[0057] The present embodiment relates to a kind of preparation method of graphene-nitrile latex scrub gloves, and described preparation method comprises the steps:

[0058] Step 1, preparing ball abrasive, thickened slurry and nitrile abrasive slurry.

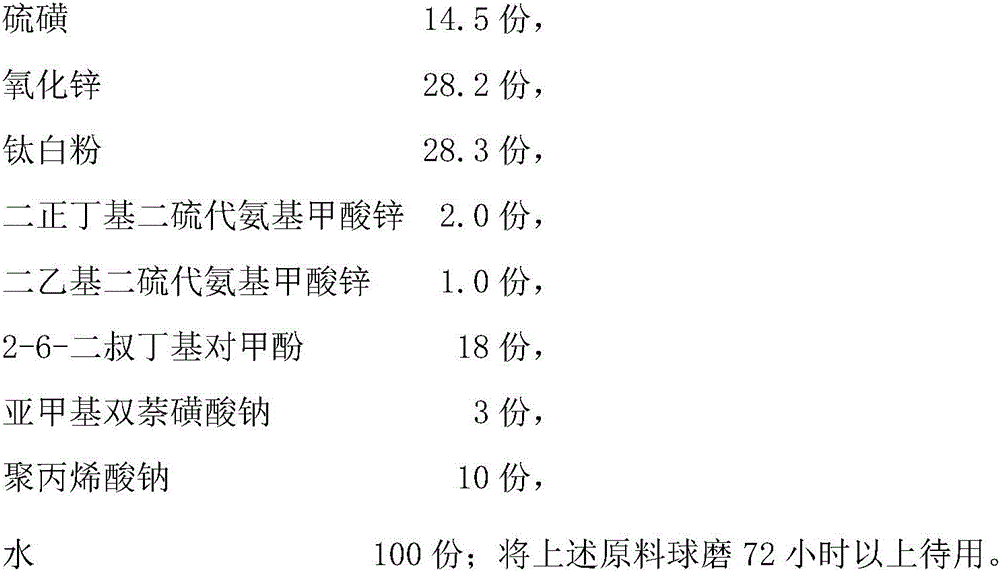

[0059] The preparation of ball mill: described ball mill comprises each component of following parts by weight:

[0060]

[0061]

[0062] The preparation of thickening slurry: described thickening slurry comprises each component of following parts by weight:

[0063] Sodium polyacrylate 4 parts,

[0064] 10 parts of water,

[0065] 0.3 parts of 10wt% KOH;

[0066] When preparing, add the sodium polyacrylate into water, stir evenly, then add the KOH, stir and place before use.

[0067] The preparation of graphene-nitrile latex frosted composite slurry: 1 weight part of 10wt% KOH and 7 weight parts of water are mixed well, slowly add in the 100 weight parts of nitrile rubber (solid content 40%) under stirring state; I...

Embodiment 3

[0074] The present embodiment relates to a kind of preparation method of graphene-nitrile latex scrub gloves, and described preparation method comprises the steps:

[0075] Step 1, preparing ball abrasive, thickening slurry and graphene-nitrile latex frosting composite slurry.

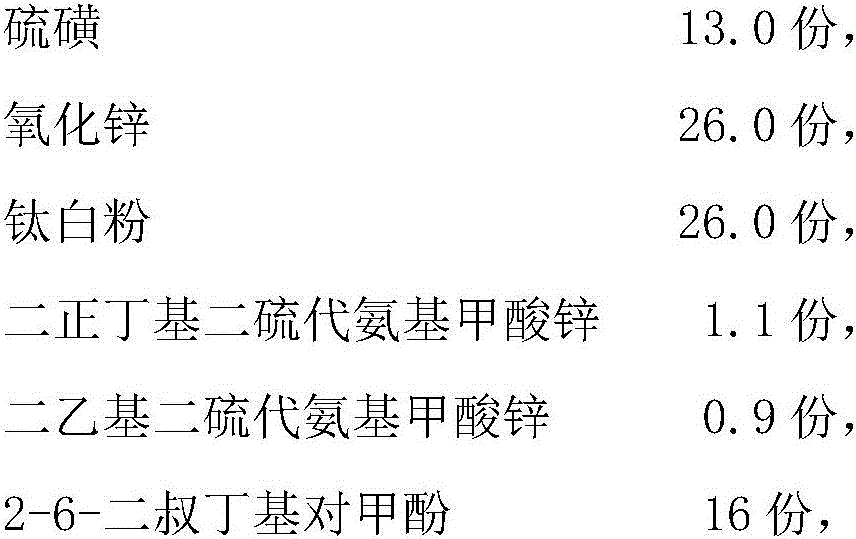

[0076] The preparation of ball mill: described ball mill comprises each component of following parts by weight:

[0077]

[0078] The preparation of thickening slurry: described thickening slurry comprises each component of following parts by weight:

[0079] Sodium carboxymethyl cellulose 5 parts,

[0080] 10 parts of water,

[0081] 0.5 parts of 10wt% KOH;

[0082] When preparing, add the sodium carboxymethyl cellulose into water, stir evenly, then add the KOH, stir and place before use.

[0083] The preparation of graphene-nitrile latex frosted composite slurry: 10wt%KOH2 weight parts and water 8 weight parts are mixed well, under stirring state slowly add in the 100 weight parts of nitrile r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com