Water-based graphene conductive polyester resin and preparation method thereof

A water-based graphene and polyester resin technology, which is applied in the field of organic synthesis, can solve the problems of difficult dispersion of graphene, and achieve the effect of huge market potential, strong thermal conductivity and broad prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

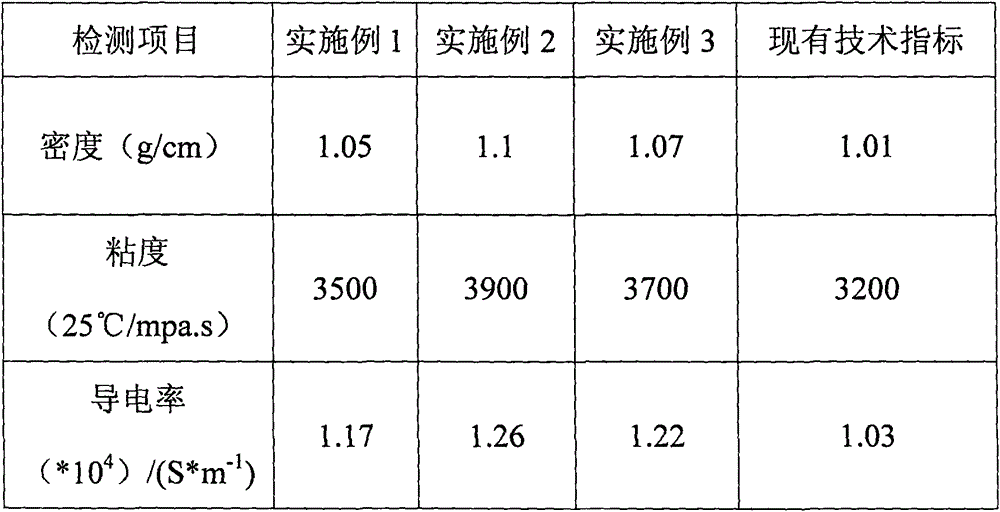

Examples

Embodiment 1

[0027] A water-based graphene conductive polyester resin, the raw material of the water-based graphene conductive polyester resin includes neopentyl glycol, cyclohexanediol, trimethylolpropane, isophthalic acid, refined adipic acid, graphene xylene.

[0028] A preparation method of water-based graphene conductive polyester resin, comprising the steps of:

[0029] (1) Pre-production inspection

[0030] First check the cleanliness of the reactor, the sealing of the accessories of the reactor, the operation of the transmission device of the reactor and the emptying of the oil-water separator, and then check the specifications of the raw materials used in production;

[0031] (2) Melting of materials

[0032] Add the qualified neopentyl glycol, cyclohexanediol, trimethylolpropane, isophthalic acid, purified adipic acid, and graphene xylene into the reactor and then cover the lid of the reactor for melting. The temperature rises to 130°C within 2 hours, neopentyl glycol 15kg, cy...

Embodiment 2

[0044] A water-based graphene conductive polyester resin, the raw material of the water-based graphene conductive polyester resin includes neopentyl glycol, cyclohexanediol, trimethylolpropane, isophthalic acid, refined adipic acid, graphene xylene.

[0045] A preparation method of water-based graphene conductive polyester resin, comprising the steps of:

[0046] (1) Pre-production inspection

[0047] First check the cleanliness of the reactor, the sealing of the accessories of the reactor, the operation of the transmission device of the reactor and the emptying of the oil-water separator, and then check the specifications of the raw materials used in production;

[0048] (2) Melting of materials

[0049] Add the qualified neopentyl glycol, cyclohexanediol, trimethylolpropane, isophthalic acid, purified adipic acid, and graphene xylene into the reactor and then cover the lid of the reactor for melting. The temperature rises to 135°C within 3 hours, neopentyl glycol 15.4kg, ...

Embodiment 3

[0061] A water-based graphene conductive polyester resin, the raw material of the water-based graphene conductive polyester resin includes neopentyl glycol, cyclohexanediol, trimethylolpropane, isophthalic acid, refined adipic acid, graphene xylene.

[0062] A preparation method of water-based graphene conductive polyester resin, comprising the steps of:

[0063] (1) Pre-production inspection

[0064] First check the cleanliness of the reactor, the sealing of the accessories of the reactor, the operation of the transmission device of the reactor and the emptying of the oil-water separator, and then check the specifications of the raw materials used in production;

[0065] (2) Melting of materials

[0066] Add the qualified neopentyl glycol, cyclohexanediol, trimethylolpropane, isophthalic acid, purified adipic acid, and graphene xylene into the reactor and then cover the lid of the reactor for melting. The temperature rises to 140°C within 4 hours, neopentyl glycol 15.8kg, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com