Iron-carbon pipe component capable of purifying waste water, integrated magnetoelectric oxidation biological filter chamber and application system

A technology of biological filter and pipe components, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc. The integration of mud and water cannot solve the problems of backwashing concentrated liquid treatment and electroplating wastewater treatment and reuse, and increases the cost of engineering manufacturing and use, so as to improve the efficiency of wastewater treatment, shorten the distance of swimming, and save the floor area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

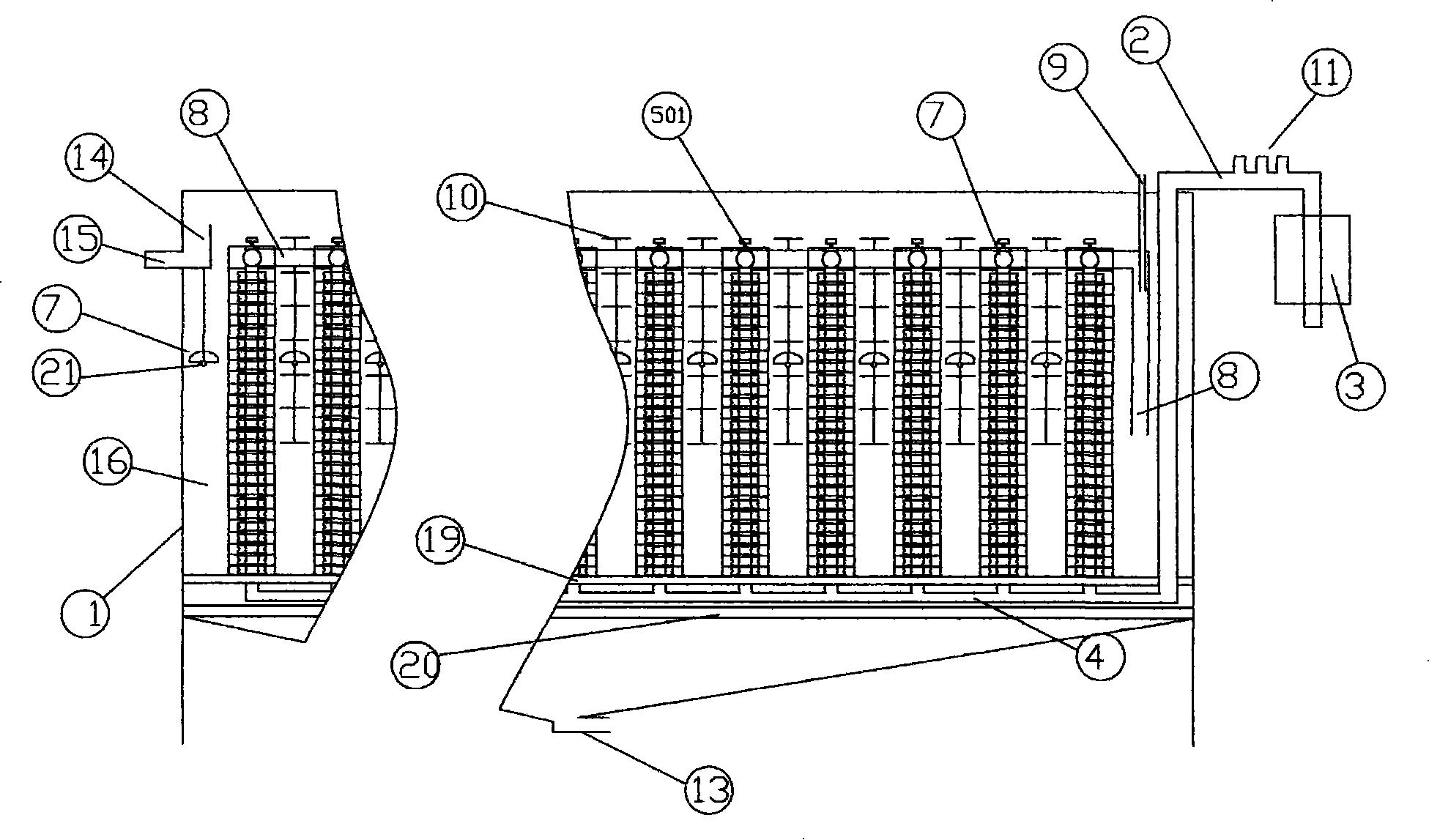

[0124] This example uses magnetoelectric advanced oxidation to carry out advanced oxidation and high-efficiency desalination of pollutants in electroplating wastewater, applies ultrafiltration as security filtration, and finally uses nanofiltration or RO membrane to produce water for reuse and electroplating wastewater magnetoelectric advanced oxidation Instances of self-control processing reuse. Such as Figure 4 As shown, the present embodiment includes a waste water collection pool 100, a cyanide-containing waste water collection pool 103, a magnetoelectric oxidation biological filter 105, a sludge pool 104, and an ion exchange pool 102, and the waste water collection pool 100 can collect chromium-containing waste water and clean Wastewater, wastewater collection tank 100 is equipped with a pH meter and a liquid level gauge, and acidic substances can be optionally added therein; the cyanide-containing wastewater collection tank 103 is equipped with a pH meter and a liquid l...

Embodiment 2

[0128] This embodiment is applied to a treatment system for biochemically difficult wastewater (garbage permeate).

[0129] At present, the reverse osmosis method has been widely used to treat high-concentration and high-salt sewage, and has mature operating experience in the treatment of leachate from municipal solid waste landfills. At present, some domestic companies are trying to introduce German technology and apply it to Chinese waste Incineration plant leachate treatment. However, the waste leachate from incineration plants is different from landfill leachate in that the content of organic matter and suspended solids is much higher, and the amount of reverse osmosis concentrate is much larger than that of landfill leachate. Generally speaking, the concentration ratio of the secondary RO system for treating landfill leachate can reach 10%, but when it is used for leachate treatment, it has been proved by experiments that the concentration ratio is only 50%, and the rever...

Embodiment 3

[0145] This embodiment is applied to ultrafiltration, nanofiltration or RO membrane to generate concentrated liquid treatment system. Such as Figure 6 As shown, the present embodiment also includes a waste water collection pool 100, a sludge pool 104, and a magnetoelectric oxidation biological filter 105. The waste water collection pool 100 receives RO membrane concentrated waste water, and a pH meter and a liquid level gauge are provided therein. Acids can also be added optionally. The water outlet of the collection tank 100 is in communication with the water inlet of the magnetoelectric oxidation biological filter 105 . On the water inlet pipeline of the magneto-electric oxidation biological filter 105, a magnetizer 3, a flow meter and a lifting pump 101 are also provided, and an automatic control dosing port 11 is arranged before the water inlet, and the dosing amount of the self-control dosing port 11 is determined by the dosing Pump control, adding activated carbon pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com