Electroslag remelting crystallizer and manufacturing method thereof

A technology of electroslag remelting and crystallizer, which is applied in the field of electroslag refining, can solve problems such as poor heat exchange effect of crystallizer, poor thermal conductivity of carbon steel, cracks at copper-steel joints, etc., to improve quality and heat exchange effect , good plasticity, the effect of solving the problem of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

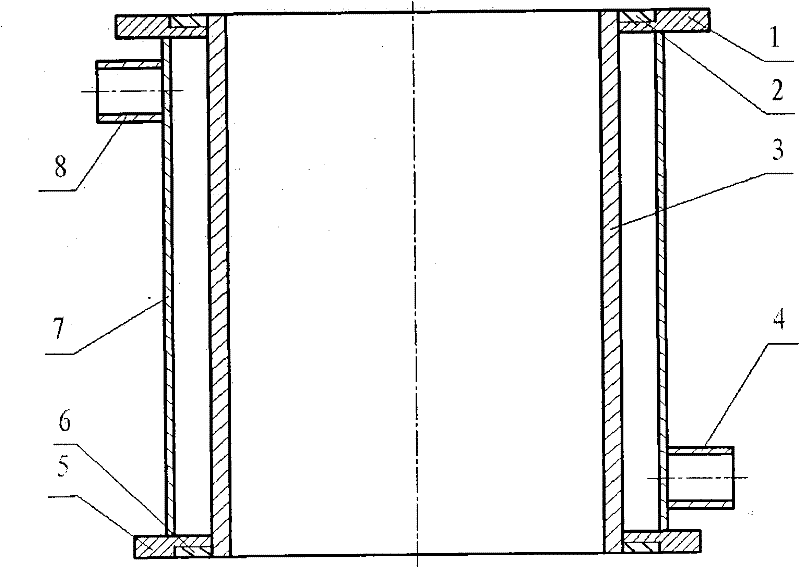

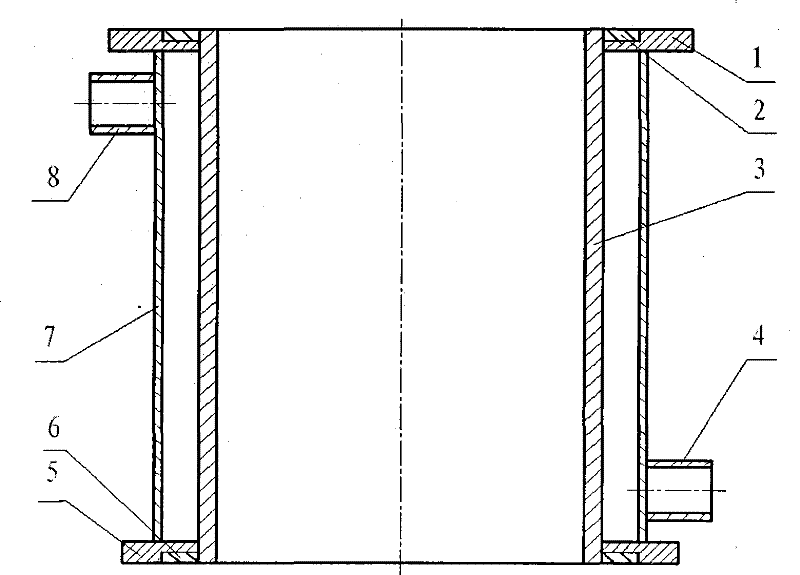

[0019] Such as figure 1 As shown, the present invention includes a copper inner cylinder 3, a steel outer cylinder 7, a water inlet pipe 4 arranged at the lower part of the outer cylinder 7, a water outlet pipe 8 arranged on the upper part of the outer cylinder 7, and welded to the inner and outer cylinders. The upper flange and the lower flange together, wherein the upper flange is composed of two parts of outer circle 1 and inner circle 2, wherein outer circle 1 is made of steel material, and the upper half of inner circle 2 is made of copper material, The lower half is made of steel; the lower flange is composed of two parts: outer circle 5 and inner circle 6, in which outer circle 5 is made of steel material, the upper half of inner circle 6 is made of steel material, and the lower half is made of copper Material; The inner cylinder 3 and the upper flange are welded together, and the outer cylinder 7 and the lower flange are welded together, and the two are relatively welde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com