Pumped storage upper reservoir dry-wet cycle lower thermal insulation anti-seepage reservoir bank structure and construction method thereof

A technology of pumped storage and dry-wet cycle, which is applied in water conservancy projects, sea area projects, coastline protection, etc. It can solve the problems of complex construction process, difficult connection and easy aging, etc., and achieve the effect of improving anti-seepage technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

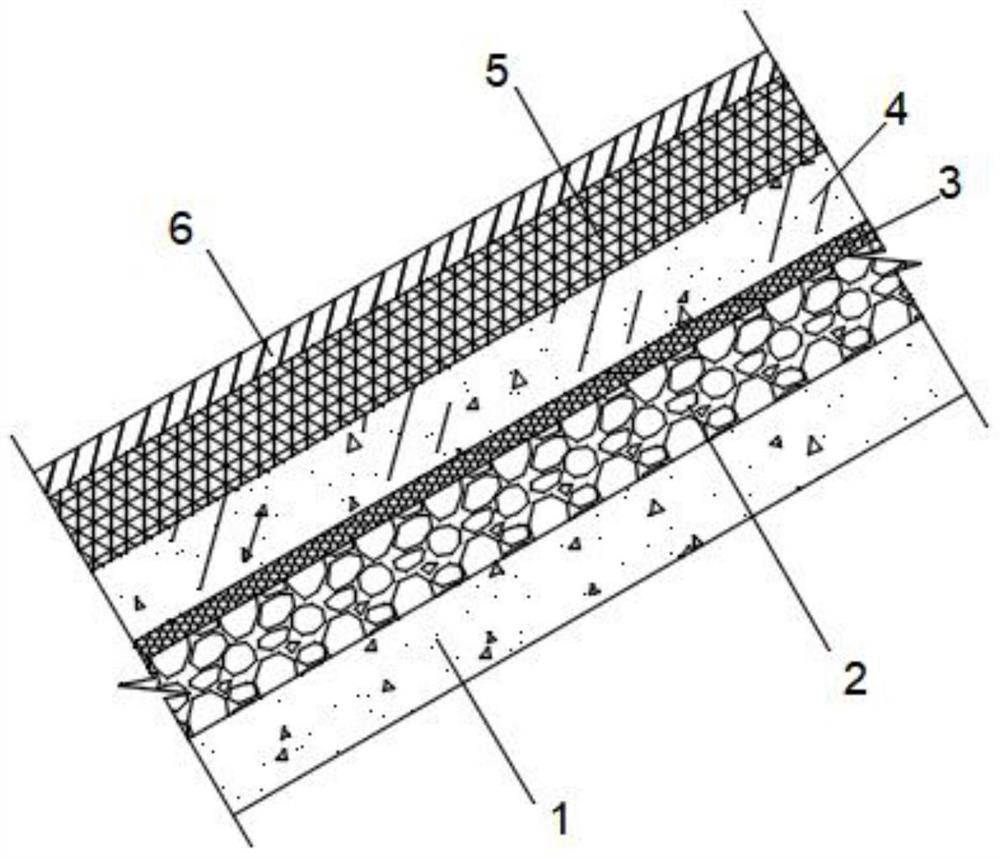

[0027] see figure 1 , This embodiment discloses a bank structure of heat preservation and anti-seepage reservoir under the dry-wet cycle of pumped storage upper reservoir, including a crushed stone cushion, a leveling cement layer 1, an asphalt layer arranged on the water-facing side of the bank slope from the inside to the outside in sequence Stabilized gravel drainage layer 2, polyester mesh 3, fiber-mixed asphalt concrete layer 4, thermal insulation layer 5 and mastic sealing layer 6.

[0028] The leveling cementitious layer 1, as the bottom layer of the anti-seepage panel, provides a solid foundation for the anti-seepage layer through good cementation with the gravel cushion. The material of the leveling cementitious layer 1 is asphalt concrete mixture, and the leveling cementation The porosity of layer 1 is 10% to 15%. In the asphalt concrete mixture used in the leveling cementitious layer 1, the asphalt content is 4% to 5%, the maximum particle size of the aggregate is ...

Embodiment 2

[0036] This embodiment discloses the construction method of the heat-insulating and anti-seepage reservoir bank structure under the dry-wet cycle of the pumped-storage upper reservoir described in Embodiment 1, which includes the following steps:

[0037] 1) Construction of the leveling cementitious layer 1: After the construction of the crushed stone cushion is completed, the asphalt concrete mixture is spread on the crushed stone cushion and rolled. Specifically, after the construction of the lower gravel cushion is completed, the mechanical paving and manual paving of the bank bank shall be mechanically paved first, with a paving width of 4m and a virtual paving thickness of 12cm. This process requires special hoisting. Equipment, manual paving is used for the blind area of mechanical paving, mainly on the upper and lower reverse arc sections of the slope. After the paving is completed, the rolling construction is carried out, and the initial rolling is not less than two t...

Embodiment 3

[0045] see figure 1 , This embodiment discloses a bank structure of heat preservation and anti-seepage reservoir under the dry-wet cycle of pumped storage upper reservoir, including a crushed stone cushion, a leveling cement layer 1, an asphalt layer arranged on the water-facing side of the bank slope from the inside to the outside in sequence Stabilized gravel drainage layer 2, polyester mesh 3, fiber-mixed asphalt concrete layer 4, thermal insulation layer 5 and mastic sealing layer 6.

[0046] The material of the leveling cementitious layer 1 is an asphalt concrete mixture, and the porosity of the leveling cementitious layer 1 is 10% to 15%.

[0047] The material of the asphalt-stabilized crushed stone drainage layer 2 is an asphalt-crushed stone mixture, and the porosity of the asphalt-stabilized crushed stone drainage layer 2 is 15% to 25%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Monofilament length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com