Preparation method of modified polyester fancy style knitted fabric

A technology for modifying polyester and knitted fabrics, applied in knitting, weft knitting, fabric surface trimming, etc., can solve the problems of polyester fiber rubbing fastness, sublimation fastness, poor spinnability, carrier toxicity, etc. Good fastness and sublimation fastness, improved antistatic performance, and improved anti-pilling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1, such as figure 1 Shown, a kind of preparation method of modified polyester fancy style knitted fabric comprises the following steps:

[0021] In step A, the modified polyester fiber is selected for dyeing. The selected polyester fiber is 75D / 72F / 2 (DTY cationic 100%), and the 75D / 72F / 2 (DTY cationic 100%) is first dyed into the required different colors;

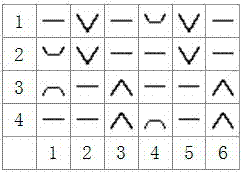

[0022] Step B, weaving the dyed 75D / 72F / 2 (DTY cationic 100%) and 105D spandex yarn into a color stripe rib structure through a double-sided thread transfer machine, wherein the odd-numbered needles are looped weaving structure loops, and the even-numbered needles are also Loop weaving structure loop;

[0023] Step C, draining the gray fabric into the water;

[0024] Step D, drying the fabric gray cloth;

[0025] Step E, performing resetting on the gray fabric, the resetting temperature is 130°C, the speed is 20m / min, and the overfeed ratio is 30%. Obtain a kind of modified polyester color striped rib ...

Embodiment 2

[0026] Example 2, such as figure 2 Shown, a kind of preparation method of modified polyester fancy style knitted fabric comprises the following steps:

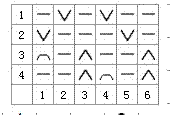

[0027]In step A, the modified polyester fiber and spandex yarn are woven into an air layer structure through a multi-track double-sided circular weft machine. In the 6-way triangular structure, the 1st and 4th lines use 50D / 72F (DTY cationic 100%) polyester, The 1st route is the weaving structure cycle of float, tuck, tuck and float; the 4th route is the cycle of tuck, float, float and tuck weaving structure; the 2nd and 5th routes use 75D / 72F / 2( DTY cationic 100%) polyester, the 2nd and 5th roads are loop forming, looping, floating thread, floating thread weaving structure cycle, the 3rd and 6th roads use 75D / 72F / 2 (DTY cationic 100%) polyester and 30D spandex For silk blended yarn, the 3rd and 6th routes are all floating, floating, looping, and looping weaving structure cycles.

[0028] Step B, washing the gray fabric in ...

Embodiment 3

[0033] Example 3, such as image 3 As shown, a method for preparing a modified polyester fancy style knitted fabric includes the following steps: In step A, the modified polyester fiber and spandex yarn are woven into a horizontal jersey structure through a single-side thread adjustment machine , in the 6-way triangular structure, the 1st, 2nd, 4th, and 5th roads use 75D / 72F (DTY) polyester, the 1st road is the weaving structure cycle of floating thread, loop forming, tucking, and floating thread, and the 2nd road is forming Loop, floating thread, floating thread, floating thread weaving structure cycle, the 4th road is looping, floating thread, floating thread, tuck weaving structure cycle, the 5th road is floating thread, loop forming, floating thread, floating thread weaving structure Circulation, 38D / 36F / 2 (DTY cationic 50%J50) polyester and 40D spandex blended yarn is used in the 3rd and 6th routes, and the 3rd and 6th routes are all floating threads, floating threads, lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com