Metal complex oxidation system and application thereof

A metal complex, oxidation system technology, applied in detergent compositions, non-surface-active detergent compositions, inorganic non-surface-active detergent compositions, etc., can solve energy consumption, water consumption, unfavorable energy saving and consumption reduction, etc problem, to achieve the effect of improving rubbing fastness, reducing soaping temperature, and good soaping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

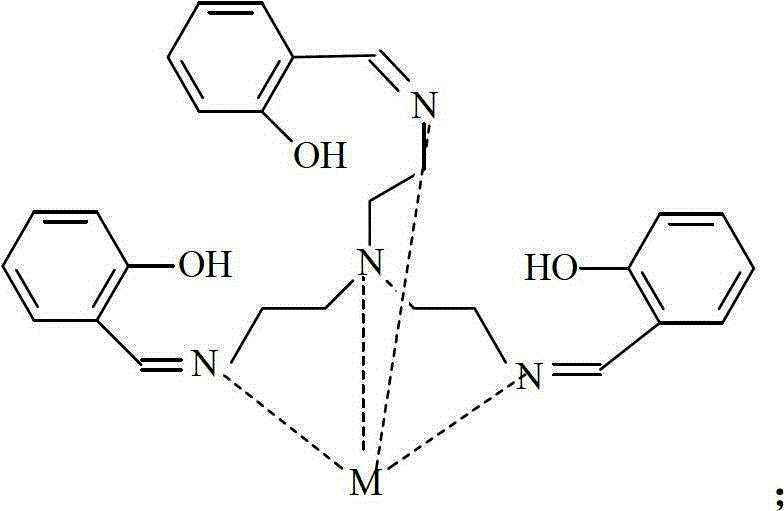

Method used

Image

Examples

Embodiment 1

[0070] Soaping fabric: pure cotton woven fabric (25tex×25 tex 140×100) dyed with reactive turquoise blue KN-R, the K / S average value before soaping is 8.2.

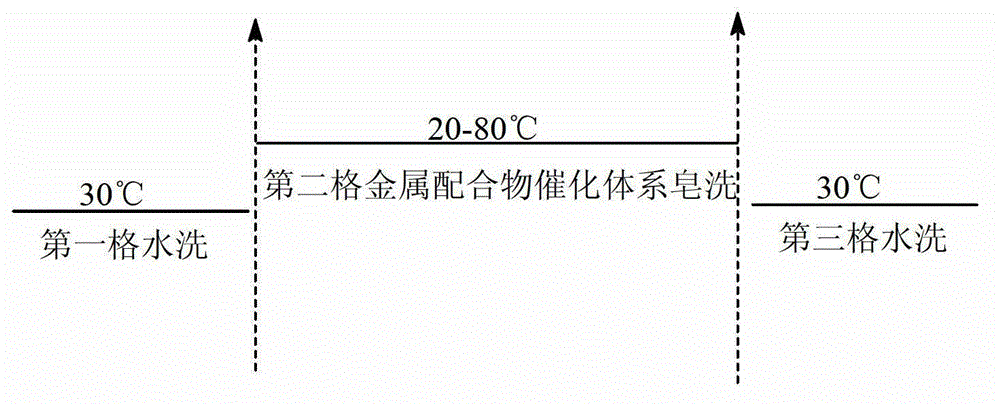

[0071] Continuous low-temperature soaping process: dyed fabric → first compartment washing (30°C) → second compartment soaping with metal complex oxidation system (N,N',N"-tris[salicylideneaminoethyl]amine ) Copper complex 5μmol / L, sodium percarbonate 2g / L, add separately when used, 50°C) → wash with cold water in the third tank (30°C) → discharge the cloth.

[0072] Continuous conventional soaping process: Dyeing fabric → cold water washing in the first compartment (30°C) → hot water washing in the second compartment (90°C) → soaping in the third compartment (soaping agent 1g / L, 95°C) → Wash in hot water (90°C) in the fourth compartment → wash in cold water (30°C) in the fifth compartment → fabric out.

[0073] Table 1 soaping effect

[0074] indicators

[0075] Note: Soaping fastness is tested according to I...

Embodiment 2

[0077] The soaped fabric is: pure cotton knitted fabric (18tex) dyed with reactive brilliant blue KN-G, K / S value is 15.2.

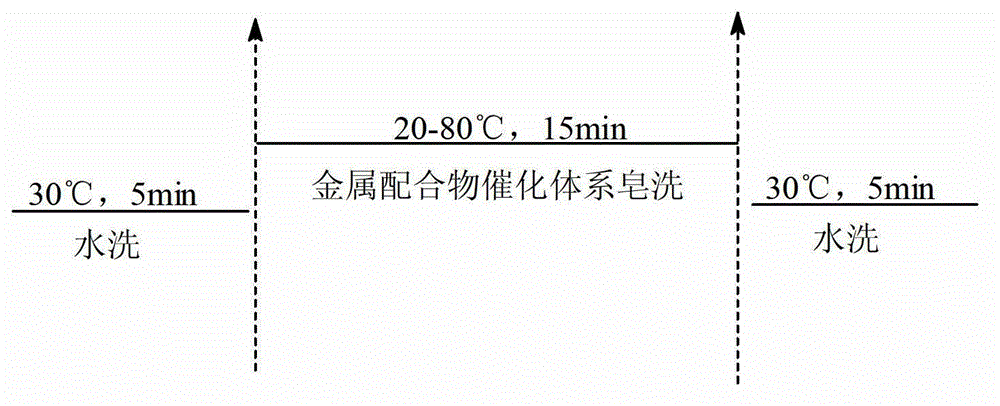

[0078] Intermittent low-temperature soaping process: dyed fabric→cold water washing (25°C, 5min)→metal complex oxidation system soaping (mellitamide macrocyclic iron complex 4μmol / L, soda ash 1g / L, hydrogen peroxide 30% 2g / L, bath ratio 1:30, 30°C, 15min) → cold water washing (25°C, 5min).

[0079] Intermittent conventional soaping process: dyed fabric → cold water washing (25°C, 5min) → hot water washing (80°C, 10min) → high temperature soaping (soaping agent A 1g / L, bath ratio 1:20, 95°C, 15min ) → hot water wash (80°C, 10min) → cold water wash (25°C, 10min).

[0080] Table 2 soaping effect

[0081] indicators

[0082] Note: Soaping fastness is tested according to ISO105-C03:1989 "Textile Color Fastness Test, Color Fastness to Washing: Test 3"; rubbing fastness: according to GB / T 3920-1997 "Textile Color Fastness Test to Resistance to Rubb...

Embodiment 3

[0084] Soaped fabric: pure cotton woven fabric (18tex×18tex 120×100) dyed with vat yellow 33, the K / S average value before soaping is 14.3.

[0085] Soaping process:

[0086] Continuous low-temperature soaping process: dyed fabrics → cold water washing in the first tank (30°C) → soaping in the second tank with metal complex oxidation system (8 μmol / L of terpyridine manganese complex, 1 g / L of sodium perborate, time Add separately, 40°C) → wash with cold water in the third tank (30°C) → discharge the cloth.

[0087] Continuous conventional soaping process: Dyeing fabric → cold water washing in the first compartment (30°C) → hot water washing in the second compartment (90°C) → soaping in the third compartment (soaping agent 1g / L, 95°C) → Wash in hot water (90°C) in the fourth compartment → wash in cold water (30°C) in the fifth compartment → fabric out.

[0088] Table 3 soaping effect

[0089] indicators

[0090] Note: Soaping fastness is tested according to ISO105-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com