Polymeric decontamination color fixing agent for fabric

A high-molecular-type, color-fixing agent technology, applied in textiles, papermaking, fiber treatment, etc., to meet the requirements of environmental protection and green production, and improve the quality of fabrics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] With 1 gram of AMPS (2-acrylamide-2-methylpropanesulfonic acid, Shandong Shouguang Runde Chemical Co., Ltd.) 20 grams of cationic monomer I (dimethyl diallyl ammonium chloride, Shandong Baomo Chemical Co., Ltd. ); 5 grams of cationic monomer II (dimethyl diallyl ammonium, Shandong Baomo Chemical Co., Ltd.); 2 grams of PVPK90-K95 (polyN-vinyl butyrolactam, Shanghai Yuang Chemical Technology Development Co., Ltd.) ; 20 grams of acrylamide (Shanghai Yuang Chemical Technology Development Co., Ltd.); 2 grams of EOPO emulsifier (Jinling Petrochemical Company) and 100 grams of deionized water were added to the four-necked bottle, nitrogen and oxygen-free, heated and stirred to 87 ° C for dissolution When the solution becomes a light yellow solution, slowly add the initiator, and at the same time raise the temperature to 95°C, react for 10 minutes, take out the measurement system viscosity, when the system viscosity rises to 5000Pa·s, add 200 grams of ice water at about 0°C, and...

Embodiment 2

[0021] 1. Pigment printing color fixing

[0022] 1.1 Conventional process flow:

[0023] Printing → drying → baking at 150°C for 3 minutes.

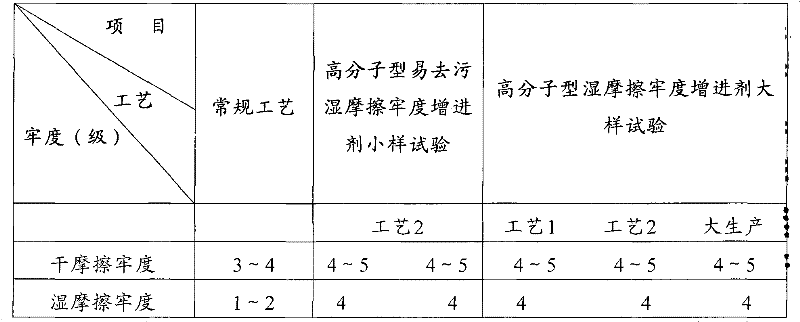

[0024] 1.2 Small sample experiment of macromolecule wet rubbing fastness enhancer, color fixing and finishing

[0025] Process 1: printing→drying→two dipping and two rolling polymer wet rubbing fastness improver 10g / L→baking at 150℃×5 minutes.

[0026] Process 2: Printing→drying→two dipping and two rolling polymer wet rubbing fastness improver 10g / L (75% rolling off rate)→baking at 180°C×60 seconds.

[0027] 1.3 Cart sample of macromolecule wet rubbing fastness improver

[0028] ① Same as sample process 1.2.

[0029] ②Improve the cart process:

[0030] Printing→drying→multiple dipping and rolling (polymer wet rubbing fastness improver 10g / L, liquid rolling rate 75%)→baking (150℃×3min or 180℃×0.5min).

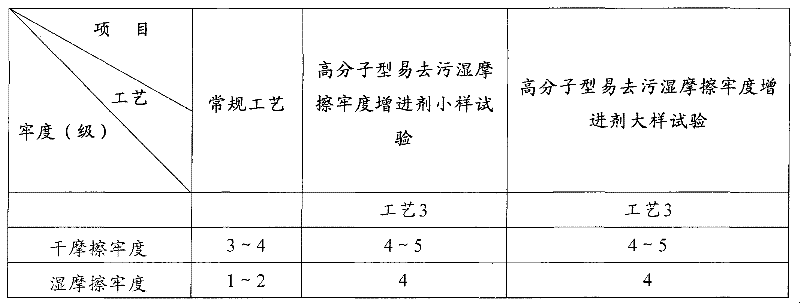

[0031] 2. Printing and color fixing finishing based on activity (large area) (grey cloth 50” 20×10 40×42 double-sided fleece)

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com