Macromolecule type wet friction fastness improver

A kind of wet rubbing fastness, polymer technology, applied in the field of fabric wet rubbing fastness improvement, fabric wet rubbing fastness improver field, to meet the requirements of environmental protection and green production, improve the effect of fabric quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] 1 gram of AMPS (2-acrylamide-2-methylpropanesulfonic acid, Shandong Shouguang Runde Chemical Co., Ltd.); 20 grams of cationic monomer I: dimethyl diallyl ammonium chloride (Shandong Baomo Chemical Co., Ltd. company); 5 grams of cationic monomer II: dimethyl diallyl ammonium (Shandong Baomo Chemical Co., Ltd.); 2 grams of PVPK90-K95 (polyN-vinyl butyrolactam, Shanghai Yuang Chemical Technology Development Co., Ltd. ); 20 grams of acrylamide (Shanghai Yuang Chemical Technology Development Co., Ltd.); 2 grams of EOPO emulsifier (Jinling Petrochemical Company) and 100 grams of deionized water were added to the four-necked bottle, nitrogen and oxygen-free, heated and stirred to 87 ° C Dissolve into a light yellow solution, slowly add the initiator, and at the same time, after the temperature reaches 95°C, take it out to measure the viscosity of the system after reacting for 10 minutes, when the viscosity of the system rises to 5000Pa·s, add 200 grams of ice water at about 0°C...

Embodiment 2

[0021] 1. Pigment printing color fixing

[0022] 1.2 Conventional process flow:

[0023] Printing → drying → baking at 150°C for 3 minutes.

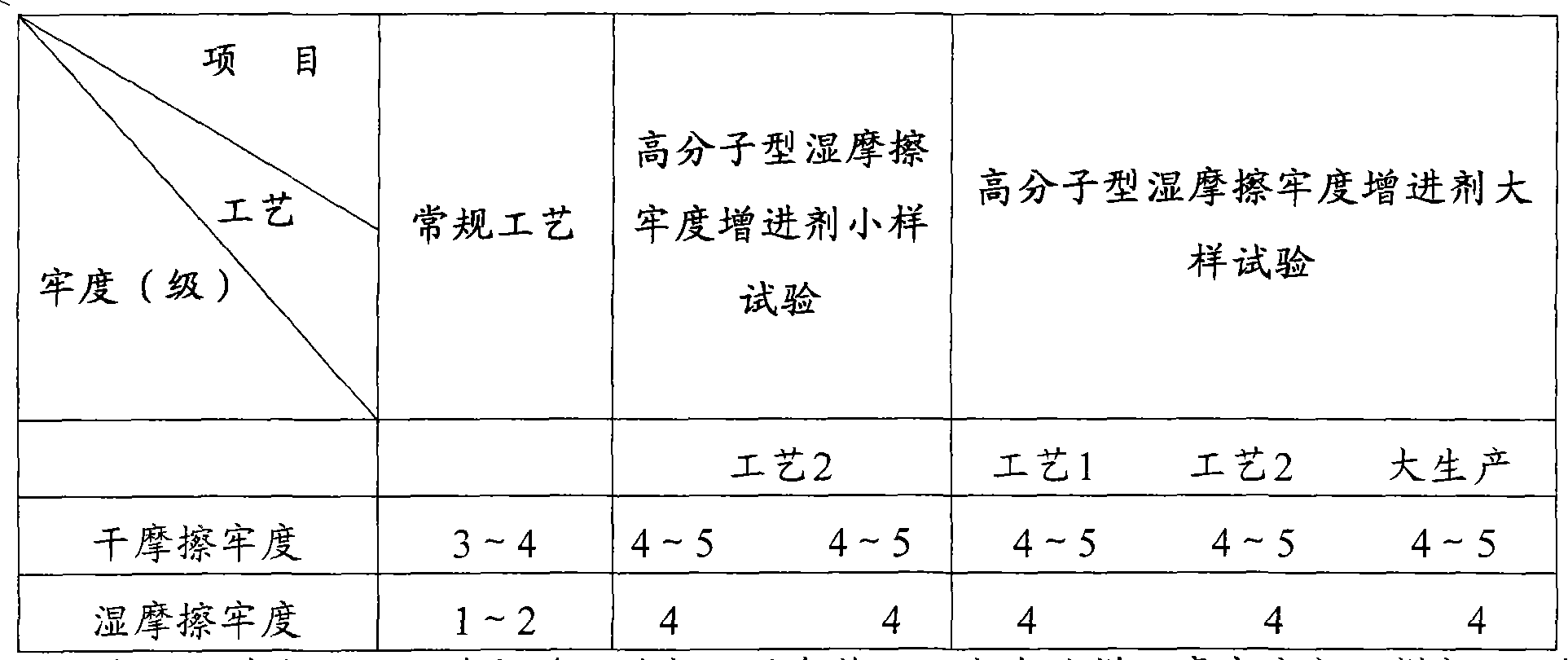

[0024] 1.3 Small sample experiment of macromolecule wet rubbing fastness enhancer, color fixing and finishing

[0025] Process 1: printing→drying→two dipping and two rolling polymer wet rubbing fastness improver 10g / L→baking at 150℃×5 minutes.

[0026] Process 2: Printing→drying→two dipping and two rolling polymer wet rubbing fastness improver 10g / L (75% rolling off rate)→baking at 180°C×60 seconds.

[0027] 1.4 Cart sample of macromolecule wet rubbing fastness improver

[0028] ①Same as sample process 1 and 2.

[0029] ②Improve the cart process:

[0030] Printing→drying→multiple dipping and rolling (10g / L polymer wet rubbing fastness improver 75%)→baking (150℃×3min or 180℃×0.5min).

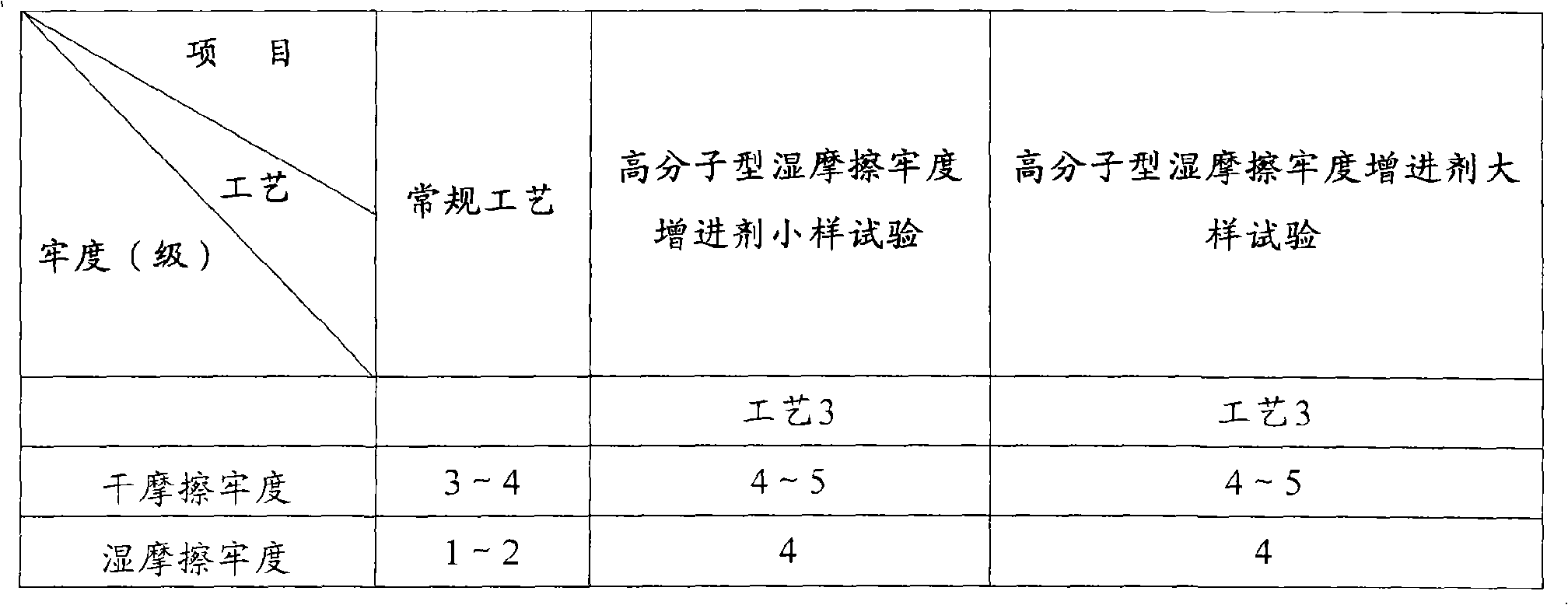

[0031] 2. Printing and color fixing finishing based on activity (large area) (grey cloth 50” 20×10 40×42 double-sided fleece)

[0032] 2.1 Conventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| color fastness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com