Reactive red dye with high washing fastness and rubbing fastness and preparation method of reactive red dye

A red dye, reactive technology, used in reactive dyes, organic dyes, chemical instruments and methods, etc., can solve the problems of washing fastness and rubbing fastness that cannot meet real life and environmental protection, and the incompatibility of dyes. , to achieve the effects of excellent fastness, bright color and less isomers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

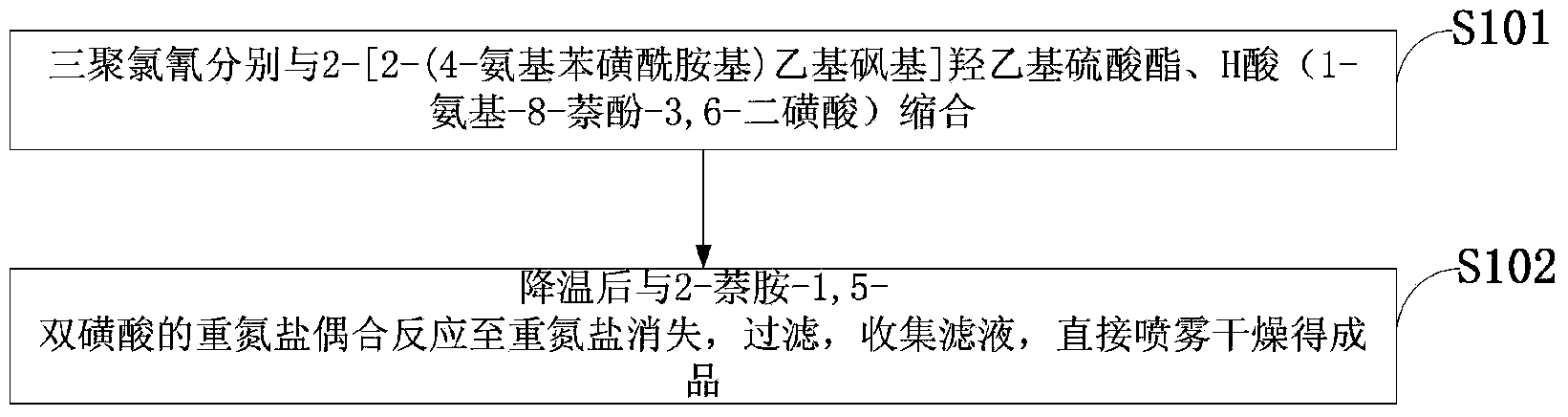

Method used

Image

Examples

Embodiment 1

[0047] 1. Condensation reaction for intermediate preparation

[0048] Add 15.8g of acetanilide to 128g of chlorosulfonic acid and react at 40-65°C for 2 hours, add dropwise 26.7g of thionyl chloride and react for 2 hours, dilute and precipitate and filter to obtain 59g (40%) of wet product p-acetamidobenzenesulfonyl chloride .

[0049] Two, thioether synthesis

[0050] Add 13.5g of 2-chloroethylamine hydrochloride to 8.7g of mercaptoethanol solution under stirring, adjust pH=4.8, and react at 55°C for 4 hours to generate 13.2g of β-hydroxyethylsulfide ethylamine. Cool down to 0°C, slowly add 59g (40%) of the tide product p-acetaminobenzenesulfonyl chloride, adjust pH=3.8, control the temperature at 0-2°C for 4 hours, separate and wash to obtain 30.7g p-acetamidobenzenesulfonamide ethyl -2-Hydroxyethyl sulfide.

[0051] 3. Sulfur ether oxidation

[0052] Add 3.15g of sodium tungstate crystals and 6g of water into the three-necked flask, and add 0.45g of 30% hydrochloric aci...

Embodiment 2

[0064] 1. Condensation reaction for intermediate preparation

[0065] Add 15.5g of acetanilide to 135g of chlorosulfonic acid and react at 50-60°C for 2 hours, add dropwise 28.4g of thionyl chloride and react for 2 hours, dilute and precipitate and filter to obtain 58.7g (40.2%) of the tide product p-acetamidobenzenesulfonate acid chloride.

[0066] Two, thioether synthesis

[0067] Add 13.2g of 2-chloroethylamine hydrochloride to 8.7g of mercaptoethanol solution under stirring, adjust pH=4.5, and react at 50°C for 4 hours to generate 13.1g of β-hydroxyethylsulfide ethylamine. Cool down to 0°C, slowly add 58.7g (40.2%) of the wet product p-acetamidobenzenesulfonyl chloride, adjust pH=4.0, control the temperature at 0-2°C for 4 hours, separate and wash to obtain 31.1g p-acetamidobenzenesulfonamide ethyl Base-2-hydroxyethyl sulfide.

[0068] 3. Sulfur ether oxidation

[0069] Add 8g of water and 3.5g of sodium tungstate crystals into the three-necked flask, and dropwise add ...

example 1

[0082] The synthetic reactive red dye of example 1 has the following characteristics compared with reactive red M-3BE:

[0083] Table 1

[0084]

[0085] During the test of the performance indicators in Table 1, the following standards were used:

[0086] GB / T2374-2007 General Conditions for Determination of Dye Dyeing

[0087] GB / T2381-2013 Dyes and dye intermediates - Determination of insoluble content

[0088] GB / T2386-2006 Determination of moisture in dyes and dye intermediates

[0089] GB / T2387-2013 Reactive dyes - Determination of shade and intensity

[0090] GB / T2389-2006 Reactive dyes - Determination of the relative content of hydrolyzed dyes and standard samples

[0091] GB / T2390-2013 Determination of pH value of dyes

[0092] GB / T2391-2006 Reactive dyes - Determination of color fixation rate

[0093] GB / T3671.1-1996 Determination method of solubility and solution stability of water-soluble dyes

[0094] GB3899.1-2007 Nomenclature of Dyestuff Products for Te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com