Activity-brilliant-red LA and preparation method thereof

A technology of reactive brilliant red and reactive bright yellow, applied in reactive dyes, dyeing methods, textiles and papermaking, etc., can solve problems such as inability to achieve, achieve high directness, improve various fastnesses, and prevent color and flower effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

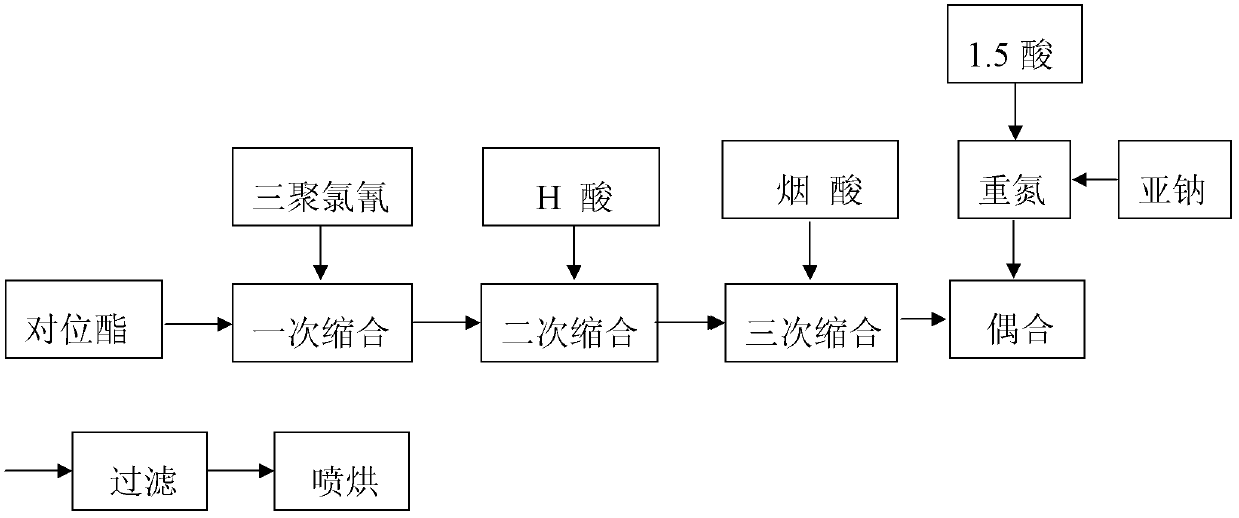

[0070] 1. Condensation reaction

[0071] In a 1000ml beaker, add 50 parts by weight (parts by weight, the same below) of ice water, 18.5 parts of cyanuric chloride for beating for 1 hour, add 29.2 parts of para-ester industrial products for beating for 1-1.5 hours, and adjust PH with 13 parts of baking soda = 2.5, temperature 0-10°C, react for 3 hours; add 33.7 parts of H acid powder to the primary condensation liquid that has reached the end point, stir evenly, heat up to 40°C, adjust PH=5 with 10.8 parts of baking soda, and react for 4 hours; Then add 12 parts of nicotinic acid, raise the temperature to 80°C, adjust the pH to 3.5 with 5.3 parts of baking soda, and react for 6 hours; after the end point is reached, cool down to 20-25°C for coupling.

[0072] 2. Nitrogen induction reaction

[0073] Add 29.6 parts by weight of 1,5-disulfonic acid-2-naphthylamine to 40 parts of ice water and 0.1 part of JS-C wetting agent for beating for 1 hour, add 11.3 parts of hydrochloric a...

Embodiment 2

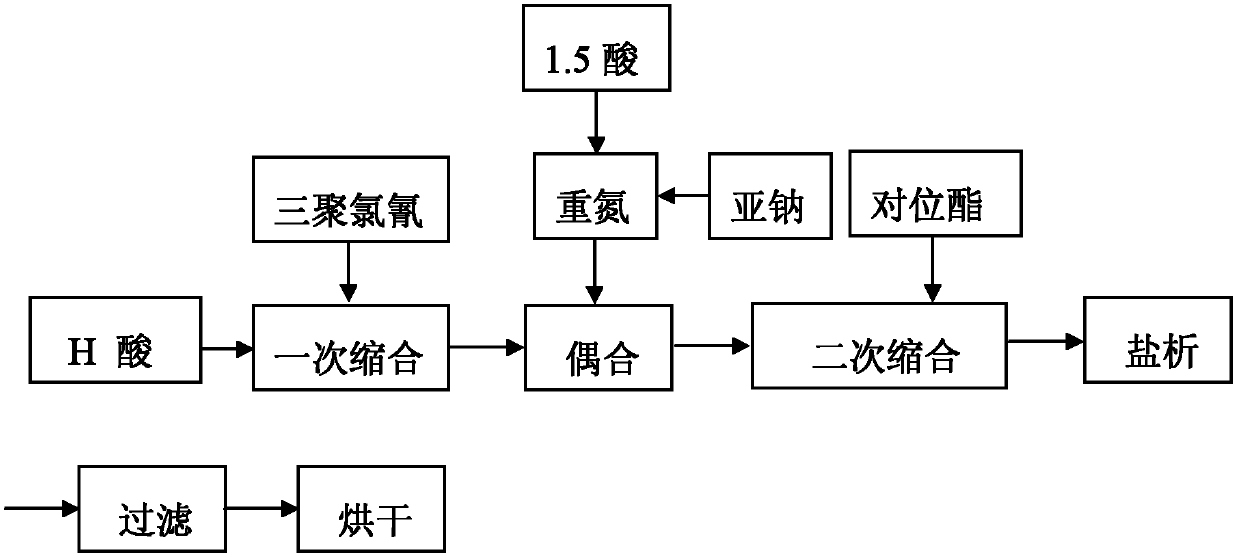

[0079] 1. Condensation reaction

[0080] Into a 1000ml beaker, add 50 parts by weight of ice water, 18.5 parts of cyanuric chloride for beating for 1 hour, add 29.2 parts of para-ester industrial products for beating for 1-1.5 hours, 13.4 parts of baking soda to adjust PH=3.0, temperature 0-10 ℃, react for 3 hours; add 33.7 parts of H acid powder to the primary condensation liquid that has reached the end point, stir evenly, then raise the temperature to 40 ℃, adjust the pH to 4.5 with 10.6 parts of baking soda, and react for 4 hours; then add 12 parts of nicotinic acid , raise the temperature to 80°C, adjust the pH to 3.5 with 5.3 parts of baking soda, and react for 6 hours; after the end point is reached, cool down to 20-25°C for coupling.

[0081] 2. Nitrogen induction reaction

[0082] Add 29.6 parts by weight of 1,5-disulfonic acid-2-naphthylamine to 40 parts of ice water and 0.1 part of JS-C wetting agent for beating for 1 hour, add 11.3 parts of hydrochloric acid and 6...

Embodiment 3

[0086] 1. Condensation reaction

[0087] Into a 1000ml beaker, add 50 parts by weight of ice water, 18.5 parts of cyanuric chloride for beating for 1 hour, add 29.2 parts of para-ester industrial products for beating for 1-1.5 hours, 13.8 parts of baking soda to adjust PH=3.5, temperature 0-10 ℃, react for 3 hours; add 33.5 parts of H acid powder to the primary condensation liquid that has reached the end point, stir evenly, heat up to 40 ℃, adjust PH=5.5 with 10.8 parts of baking soda, and react for 4 hours; then add 12.2 parts of nicotinic acid , raise the temperature to 90°C, adjust the pH to 4.5 with 5.9 parts of baking soda, and react for 6 hours; after the end point is reached, cool down to 20-25°C for coupling.

[0088] 2. Nitrogen induction reaction

[0089] Add 29.4 parts by weight of 1,5-disulfonic acid-2-naphthylamine to 40 parts of ice water and 0.1 part of JS-C wetting agent for beating for 1 hour, add 11.3 parts of hydrochloric acid and 6.75 parts of sodium nitr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com