Dyeing method of protein material

A dyeing method and protein technology, applied in dyeing method, textile and papermaking, etc., can solve the problems of refractory dye degradation, affecting the survival of aquatic organisms, human and other biological survival hazards, etc., to reduce dyeing energy consumption and avoid colored wastewater. Emissions, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

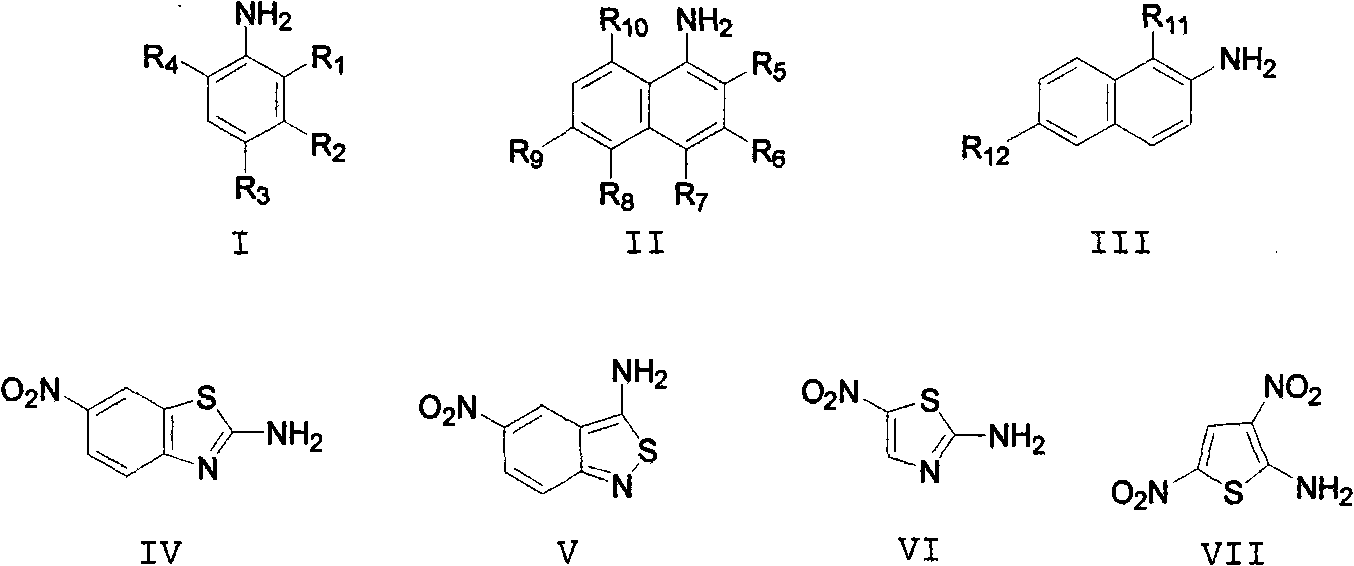

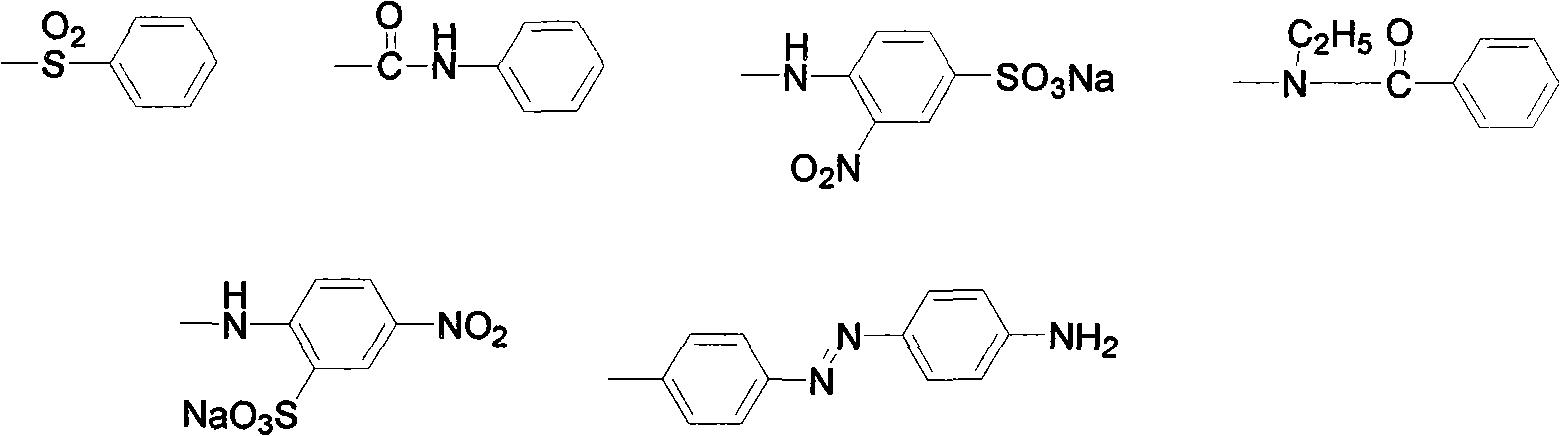

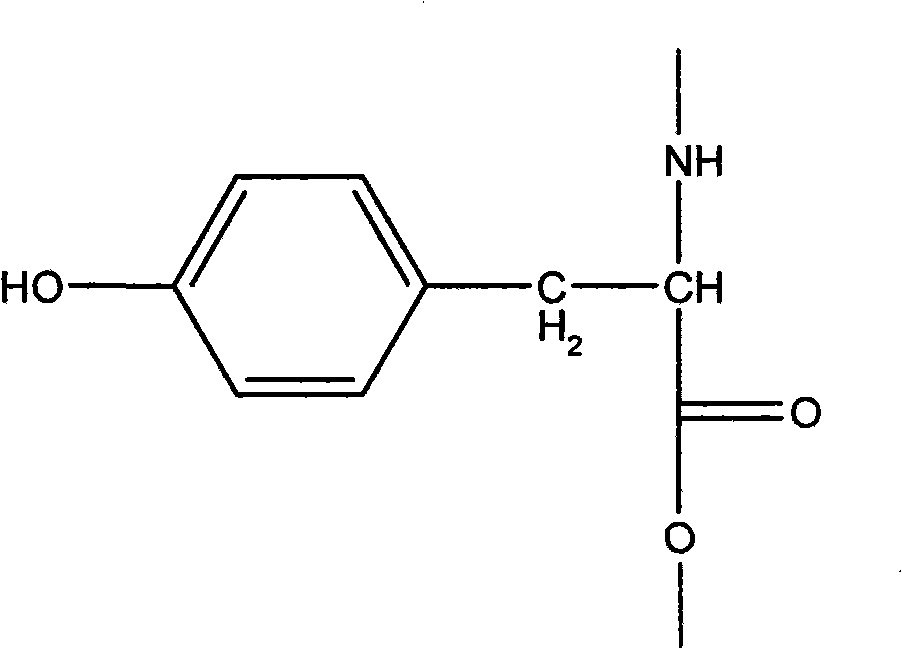

Method used

Image

Examples

Embodiment 1

[0035] To dye 10g of real silk fabric, the dyeing liquor ratio is 1:20.

[0036] First, the aromatic amine compound is prepared into a diazonium salt by a traditional method: 2.3 g of aniline is dissolved in 8.9 g of concentrated hydrochloric acid and 15 g of water, cooled to 0 ° C, and an aqueous solution of sodium nitrite (1.8 g of sodium nitrite and 4 g water), keep the reaction system at 0-5°C, drop it for about 5 minutes, and keep it warm for 30 minutes, then check it with starch-potassium iodide test paper, destroy the excess sodium nitrite with urea, and prepare the diazonium salt solution.

[0037] Immerse 10g of silk fabric in 200mL aqueous solution containing 0.2g / L sodium hydroxide and 5g / L sodium carbonate, and cool to 0°C, then add the above-mentioned clear diazonium salt solution to the system dropwise, after the dropwise addition is completed Keep warm at 0°C for 30 minutes, then warm up to room temperature and keep warm for 40 minutes to get brown silk fabric. ...

Embodiment 2

[0040] Dye woolen fabric 10g, the dyeing bath ratio is 1:100.

[0041] First use the traditional method to make the diazonium salt solution of the aromatic amine: Dissolve 0.5g of o-nitroaniline in a mixed solution of 10g of water and 1.5g of concentrated hydrochloric acid at 0°C, stir well and add 0.37g of nitroaniline to the system Sodium nitrate, and then keep it warm at 0-5°C for 30 minutes, then test it with starch-potassium iodide test paper, and destroy the excess sodium nitrite with urea to prepare a diazonium salt solution.

[0042] Immerse 10g of wool fabric into 1000mL aqueous solution containing 0.1g / L sodium hydroxide and 0.5g / L sodium carbonate, and cool to 5°C, then add the above clear diazonium salt solution to the system dropwise, the dropwise addition is complete Afterwards, keep it warm at 5°C for 120 minutes, then raise the temperature to room temperature and keep it warm for 30 minutes to obtain orange-red woolen fabric.

[0043] Then wash in hot water an...

Embodiment 3

[0045] Dyeing 10g of real silk yarn, the dyeing bath ratio is 1:50.

[0046] First, the aromatic amine compound is prepared into a diazonium salt solution by using a traditional process: 10 mL of 5% sodium hydroxide solution and 1.91 g of p-aminobenzenesulfonic acid crystals are placed in a beaker, and heated to dissolve. Dissolve 0.8g of sodium nitrite in 6mL of water, add it to the above beaker, then transfer it to a 100mL three-neck flask, and cool it to 0-5°C with an ice-water bath. Under constant stirring, slowly add a solution of 3 mL of concentrated hydrochloric acid and 10 mL of water dropwise into the above mixture, and control the temperature below 5°C. After the dropwise addition, check with starch-potassium iodide test paper (slightly blue). Then place it in an ice-water bath for 15 min to ensure the complete reaction. Excess nitrous acid is destroyed with urea.

[0047] Immerse 10g of silk yarn into 500mL aqueous solution containing 0.2g / L sodium hydroxide and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com