Method for improving light fastness of natural green colored cotton

A green and colored cotton technology, which is applied in textiles and papermaking, fiber treatment, plant fibers, etc., can solve the problems of incompletely clear discoloration mechanism of colored cotton and in-depth research, and achieve beautiful colors, good moisture permeability, and stable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

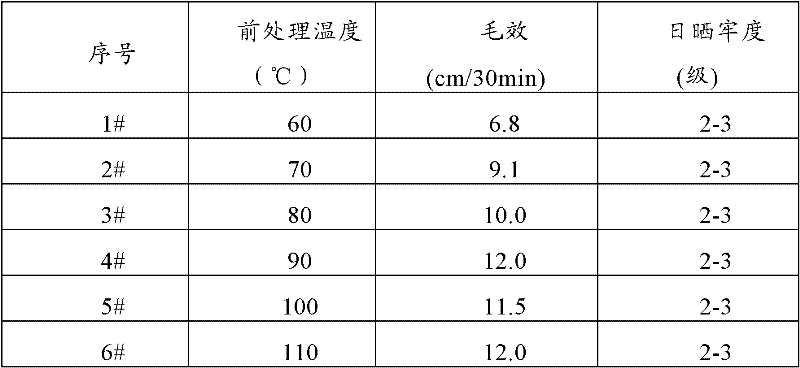

[0018] The 75% green cotton grey cloth and the pre-treatment auxiliary agent are treated at a mass ratio of 1:20 and a temperature of 60-130 DEG C for 15-75 minutes to make the grey cloth wool effect reach 10-12cm / 30min.

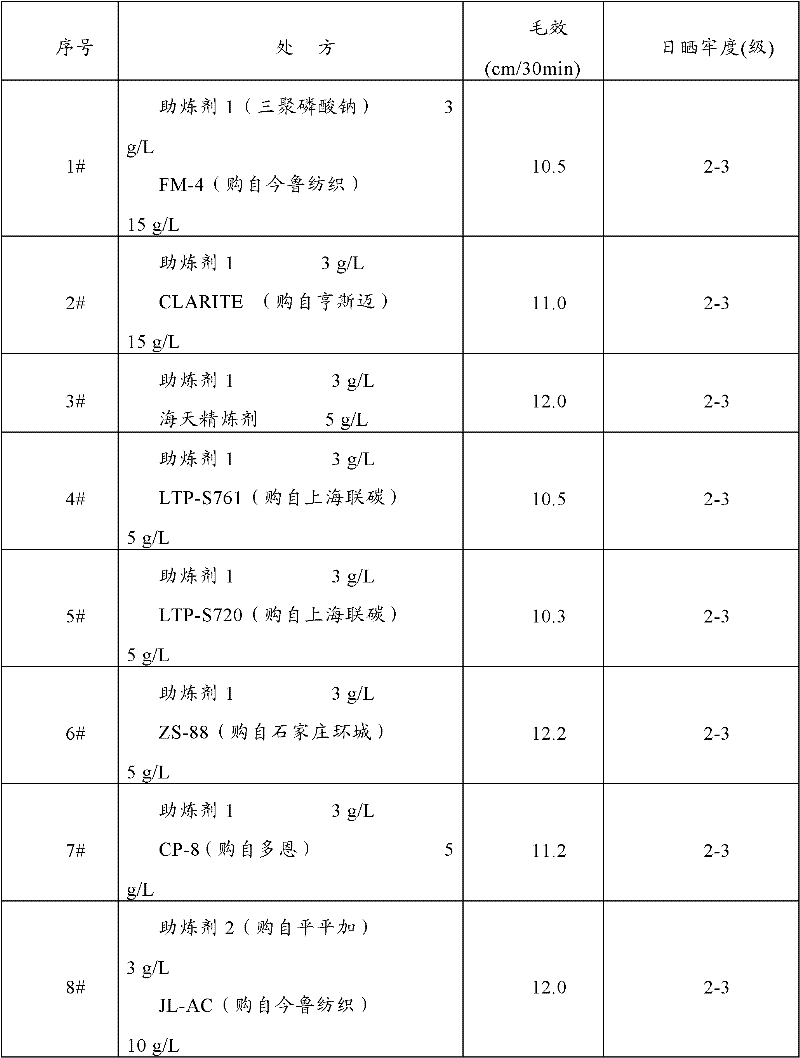

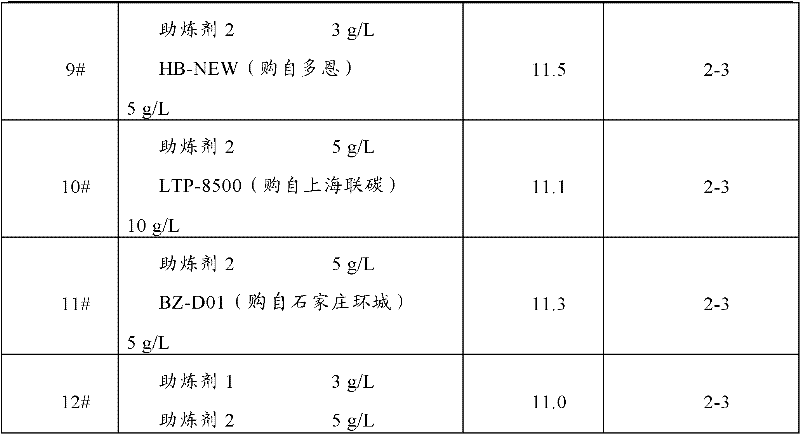

[0019] That is, 12 kinds of pre-treatment auxiliaries were used to treat 75% green cotton grey cloth under the conditions of 90°C and 30 minutes, and the wool effect value and light fastness of the treated fabrics were analyzed and compared, as shown in Table 1.

[0020] Table 1 Comparison of effects of different pretreatment additives

[0021]

[0022]

[0023] It can be seen from Table 1 that the treated green cotton fabrics have very good wool effects, and they are not much different from each other; the light fastness is only improved by 1-1.5 grades than the grey fabric, which has not yet reached the daily requirements of conventional textiles. The light fastness is level 4 standard. Among them, the determination of wool effect (determination is in accordance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gross effect | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com