Mixed solid dye and application thereof

A dye and solid technology, applied in special paper, raw material separation, fiber raw material processing, etc., can solve the problems of high toning costs and lack of dyes, and achieves reduction of paper toning costs, obvious effects, and improved utilization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

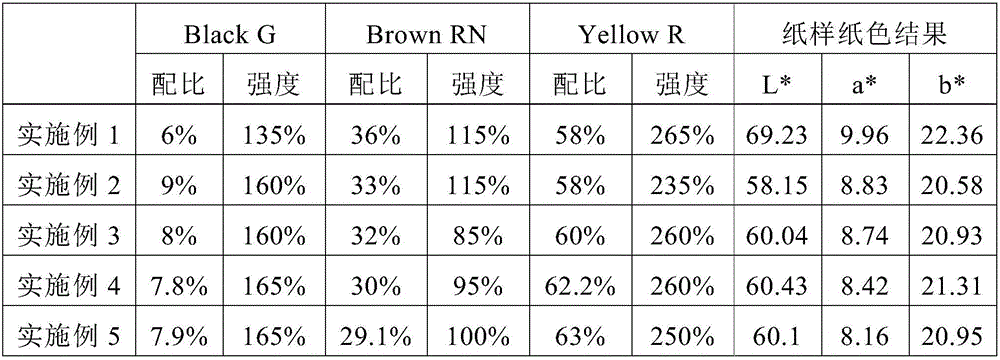

Embodiment 1-5

[0025] According to the target value of the customer's paper color: L*=60.5±1.0, a*=8.0±0.5, b*=21.0±0.5, as the goal of color matching, pulp dyeing is carried out according to the following steps:

[0026] (1) Prepare pulping and papermaking waste slurry that is uniformly dispersed;

[0027] (2) adding the mixed solid dye to water for brewing to make a mixed solid dye brewing liquid;

[0028] (3) Add dry strength agent, mixed solid dye brewing solution, cationic starch, alkyl ketene dimer, aluminum sulfate and retention aid to the slurry in sequence, stir and disperse evenly;

[0029] (4) Squeeze the mixed pulp, dry it, and shape it to obtain a paper-like product.

[0030] As mentioned above, the slurry concentration is about 3-4wt%, the addition of dry strength agent is 3kg / t slurry, the solid mixed dye is added according to the formula in Table 1, the addition amount is 3kg / t, and the addition amount of cationic starch is 10kg / t; The addition amount of ketene dimer is 8kg...

Embodiment 6

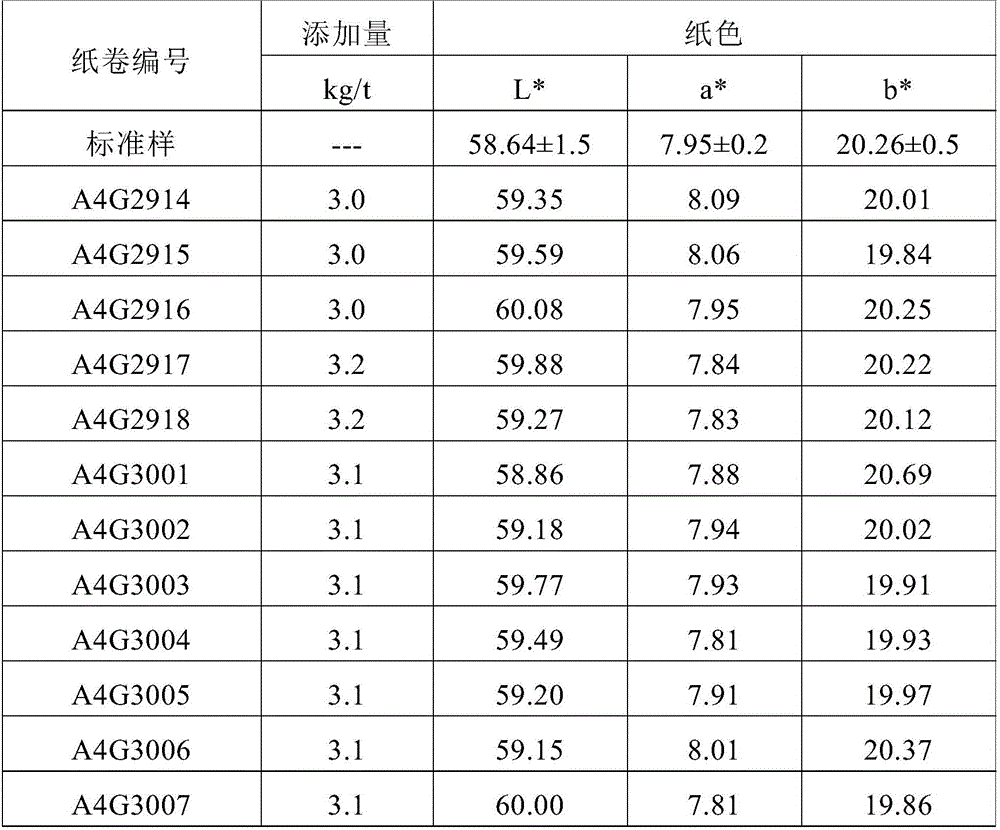

[0036] The present embodiment produces the surface paper and the core paper of corrugated paper, adopts No. 4 paper machine, No. 9 paper machine of a certain paper mill in Riau Province, Indonesia and No. 13 paper machine of a certain paper mill in Jakarta;

[0037] Capacity: 80-120T / day;

[0038] Paper machine speed: 200-255m / min;

[0039] Paper machine raw materials: waste paper boxes and scraps, scraps of waste paper core tubes, damaged paper recycling, sludge from papermaking wastewater treatment, various waste papers;

[0040] Copying process: Fourdrinier forming, ordinary mechanical pressing (two press zones), double-row dryer drying;

[0041] Chemicals: dry strength agent, alkyl ketene dimer, starch, aluminum sulfate, etc.;

[0042] Dye ratio: Black G 7.2%, Brown RN 27.3%, Yellow R 65.5%.

[0043] The specific steps are the same as those in Example 1-5, the amount of solid mixed dye added is as shown in Table 2, and the paper color results of the standard sample and ...

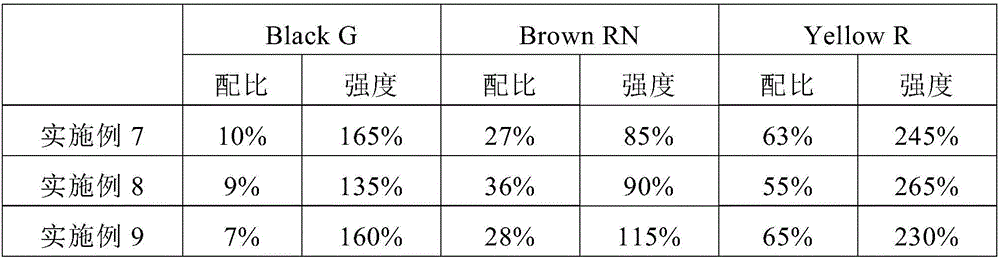

Embodiment 7-9

[0048] Embodiment 7-9 adopts different formulas and reagent additions according to different customer needs, pulp dyeing is carried out according to the following steps:

[0049] (1) prepare pulping and papermaking waste slurry uniformly dispersed, and the slurry concentration is about 3-4wt%;

[0050] (2) adding the mixed solid dye to water for brewing to make a mixed solid dye brewing liquid;

[0051] (3) Add dry strength agent, mixed solid dye brewing solution, cationic starch, alkyl ketene dimer, aluminum sulfate and retention aid to the slurry in sequence, stir and disperse evenly;

[0052] (4) Squeeze the mixed pulp, dry it, and shape it to obtain a paper-like product.

[0053] Table 3 is the formula for mixing solid dyes, and Table 4 is the amount of reagents added in dyeing.

[0054] Table 3 embodiment 7-9 mixed solid dye formula

[0055]

[0056] The reagent addition amount in table 4 embodiment 7-9 staining uses

[0057] Example 7 Example 8 Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com