Method for producing direct yellow blend dye

A production method, the technology of blending yellow, which is applied in the production field of direct blending yellow dye D-3RNL, can solve the problems of high energy consumption of particles, failure to obtain satisfactory dye products, and affect the application effect of dye products, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

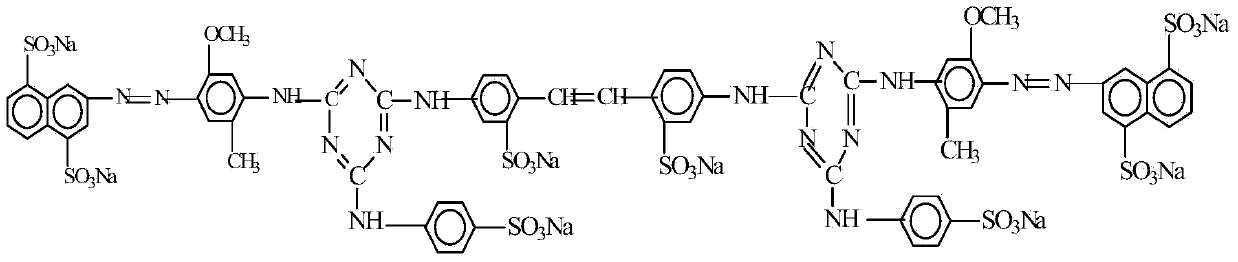

Image

Examples

Embodiment 1

[0033] A kind of production method of direct blending yellow dyestuff, comprises the steps:

[0034] (1), diazotization reaction

[0035] Mix 0.1 mol of 2-ammonia-4,8-naphthalene disulfonic acid with water and 0.15 mol of hydrochloric acid to form a suspension, add ice, add 0.1 mol of 30% sodium nitrite solution within about 1.5 hours at 5 to 8 ° C, and carry out The diazotization reaction was carried out for 2 hours to obtain a diazonium salt solution with a solid content of about 15%.

[0036] (2), coupling reaction

[0037] Mix 0.097mol of 2-methoxy-5-toluidine and 0.095mol of hydrochloric acid and heat it to 75°C to dissolve it completely to obtain 2-methoxy-5-toluidine hydrochloride solution, and cool the solution to 20 After ~25°C, add it to the diazonium salt solution to make a mixed solution, neutralize the mixed solution with sodium acetate to pH 4~5, and react at 20~25°C for 5 hours to obtain a monoazo compound solution with a solid content of about 13%.

[0038]...

Embodiment 2

[0046] This example provides a kind of production method of direct blending yellow dyestuff, and it is basically the same as embodiment 1. The difference is: the post-processing of the production process of the direct blended yellow dye adopts wet blending standardization and direct drying to obtain a finished product that is the standardized direct blended yellow dye: 100% strength 211 grams, and the shade is similar to the standard product.

Embodiment 3

[0048] This example provides a kind of production method of direct blending yellow dyestuff, and it is basically the same as embodiment 1. The difference is: the solid content of the third condensation product solution obtained in the control step (5) is 23wt%. In the production process of the direct blended yellow dye, the post-processing adopts wet blending standardization and direct drying to obtain a finished product that is the standardized direct blended yellow dye: 100% strength 211 grams, and the shade is similar to the standard product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com