Multi-color dye composition with high tone and ink-jetting ink composition

A technology of inkjet ink and composition, applied in inks, household appliances, pigment paste, etc., can solve the problems of clogging inkjet heads and reducing printing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

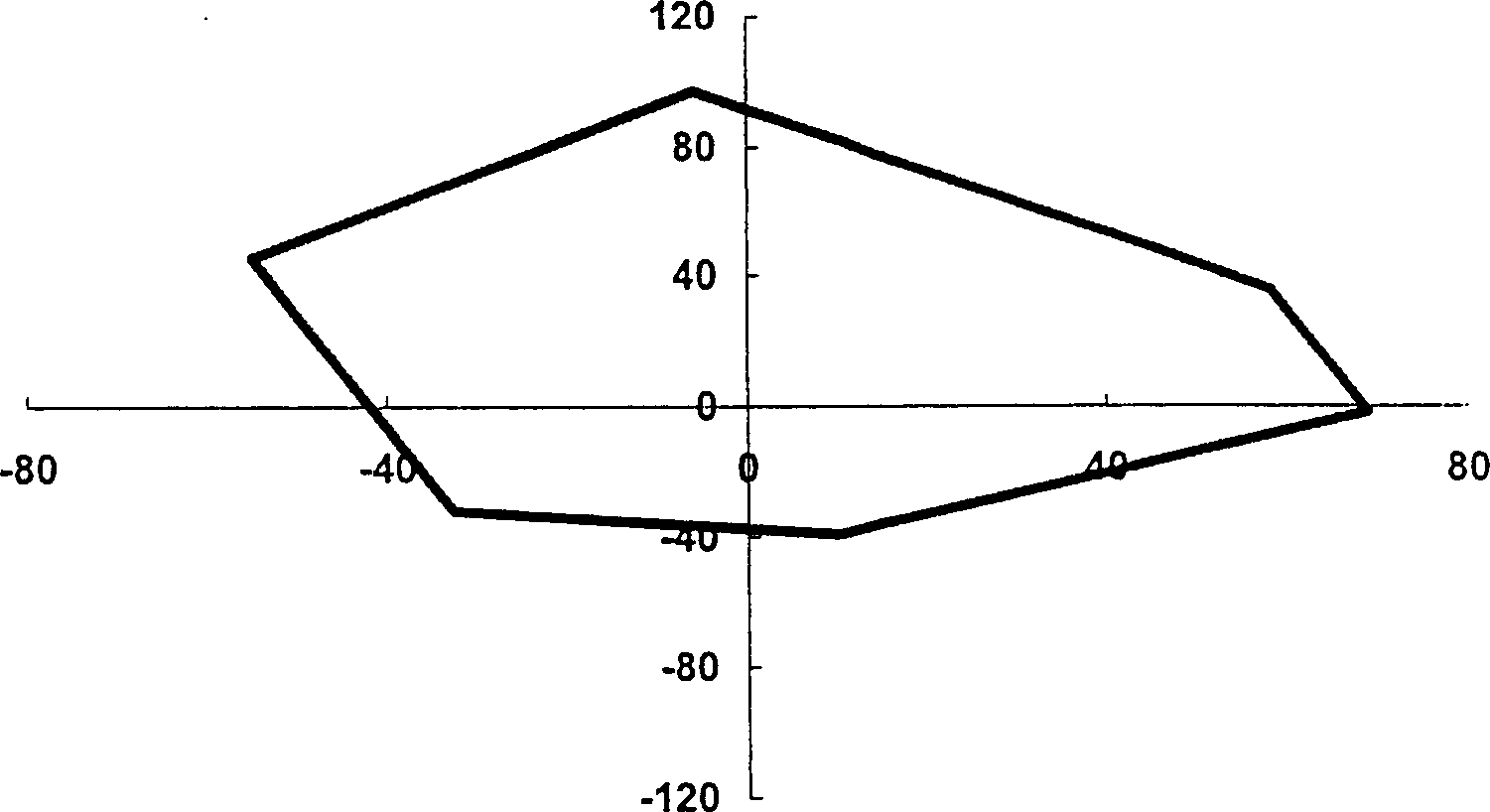

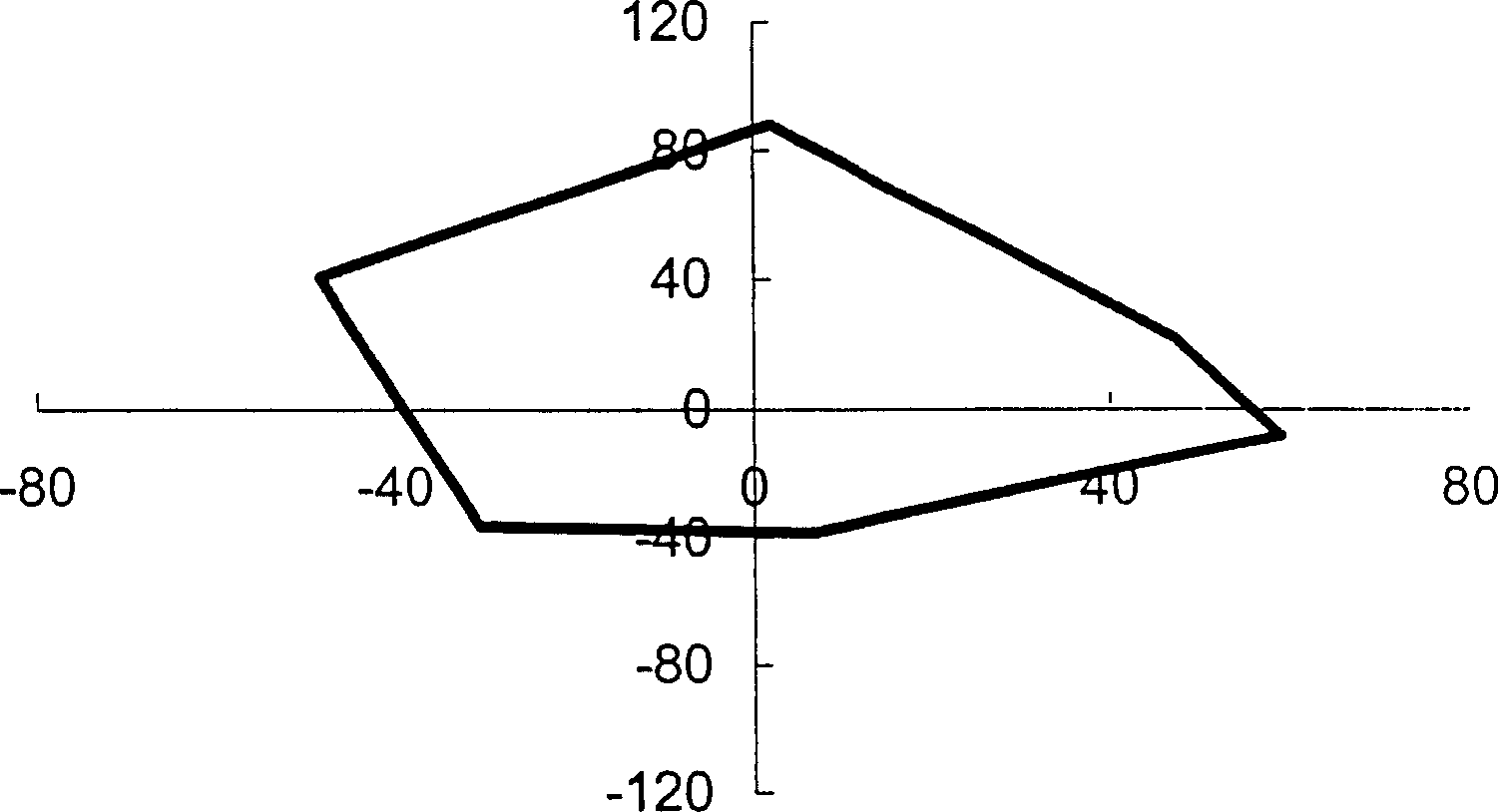

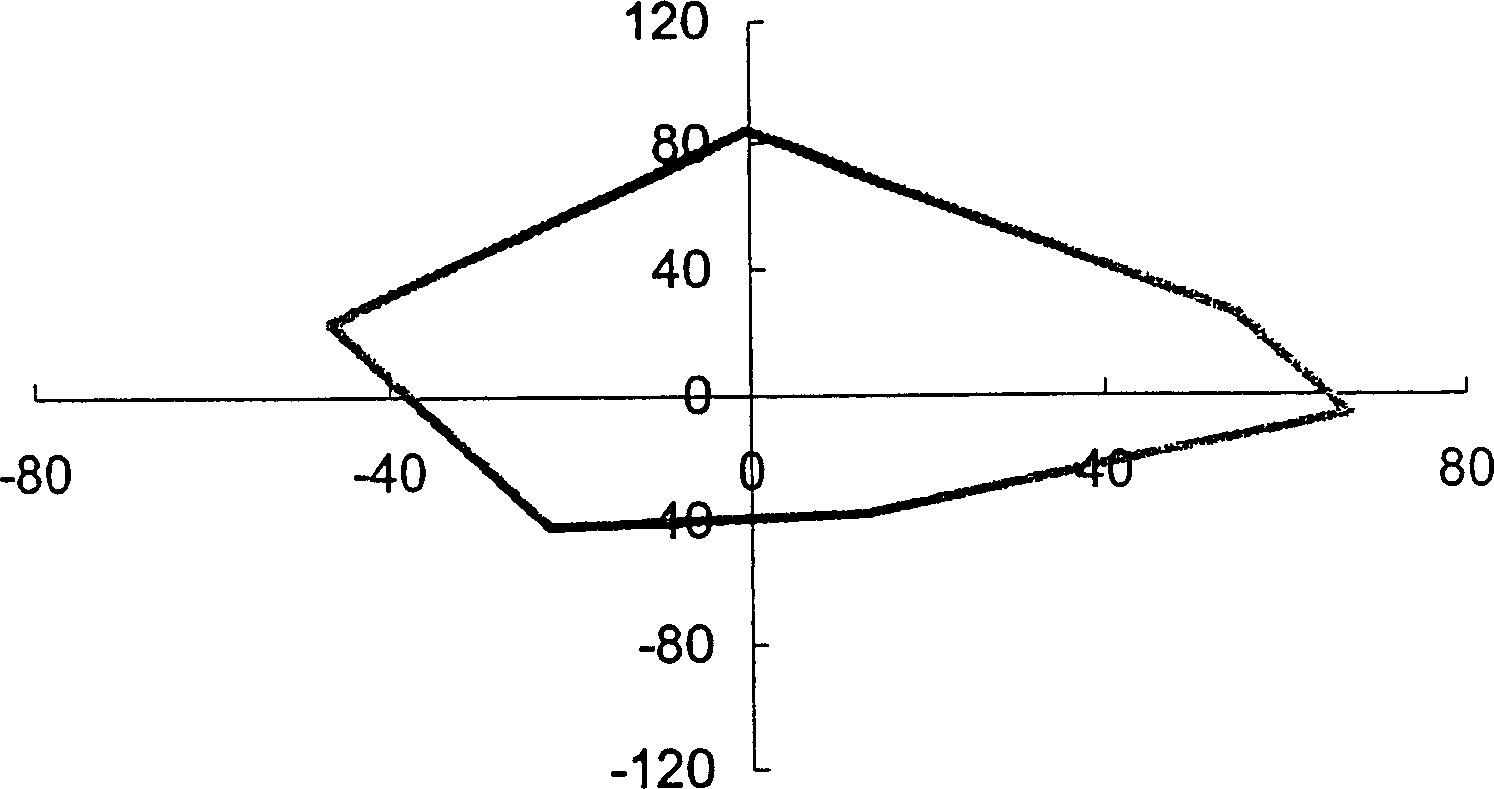

Image

Examples

Embodiment

[0039] The three-color ink composition of combined color material provided by the present invention comprises (the following % is weight %):

[0040] (1) 1.0% direct blue dye 199 (direct blue 199) (from Clariant)

[0041] 1.0% acid blue 9 (from Clariant)

[0042] 1.0% direct blue dye 87 (direct blue 87) (from orient)

[0043] 4.0% PEG 200 (polyethylene glycol 700) (from U.C.C.)

[0044] 4.0% 2-pyrrolidone (from ISP)

[0045] 4.0% 2-Ethyl-2-(hydroxymethyl)-1,3-propanediol (from Lancaster)

[0046] 2.0% Surfactant 13-S-5 (from Sino-Japanese Synthesis)

[0047] 2.0% Surfactant 13-S-7 (from Sino-Japanese Synthesis)

[0048] 3.0% surfactant OT-75 (from KYOWA)

[0049] 0.5% Surfactant 465 (from air product)

[0050] 1.0% 1,4-butanediol (from Lancaster)

[0051] 1.0% 1,6-hexanediol (from Lancaster)

[0052] 0.5% fungicide SL-700 (from KYOWA)

[0053] Deionized water

[0054] (2) 2.0% reactive red 158 (from Bayer)

[0055] 0.5% react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com