Direct dye dyeing method of polyacrylonitrile fibers

A technology of polyacrylonitrile fiber and dyeing method, which is applied in the field of fiber dyeing to achieve the effects of complete color spectrum, excellent washing and wet treatment fastness, and high dyeing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

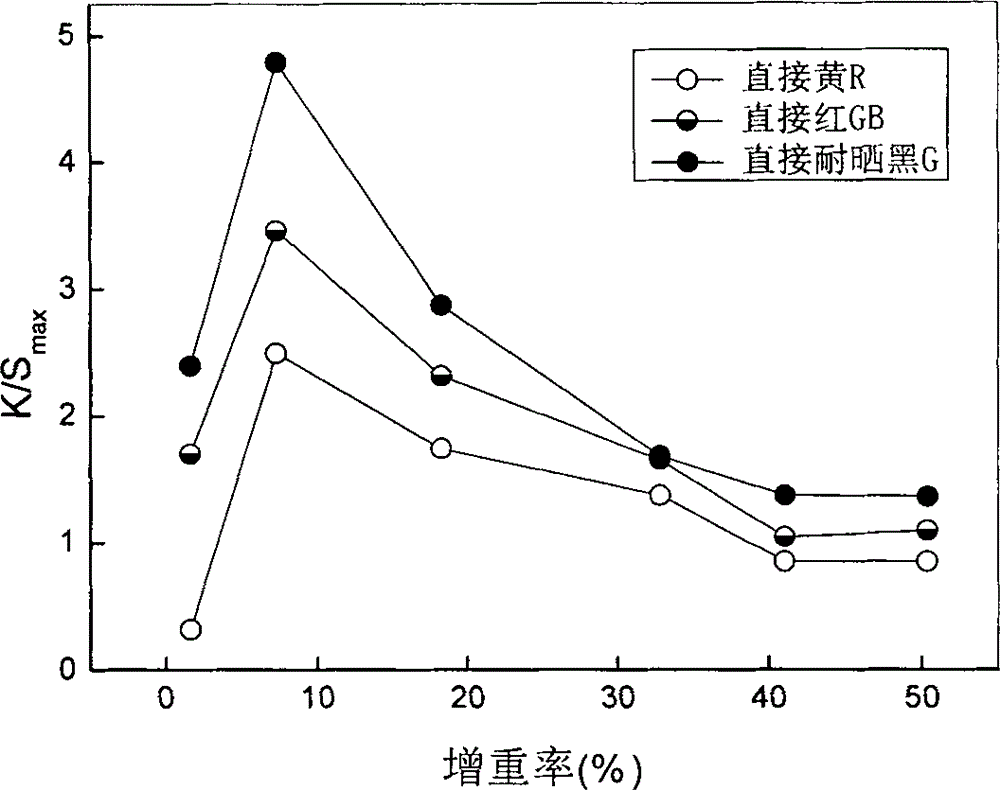

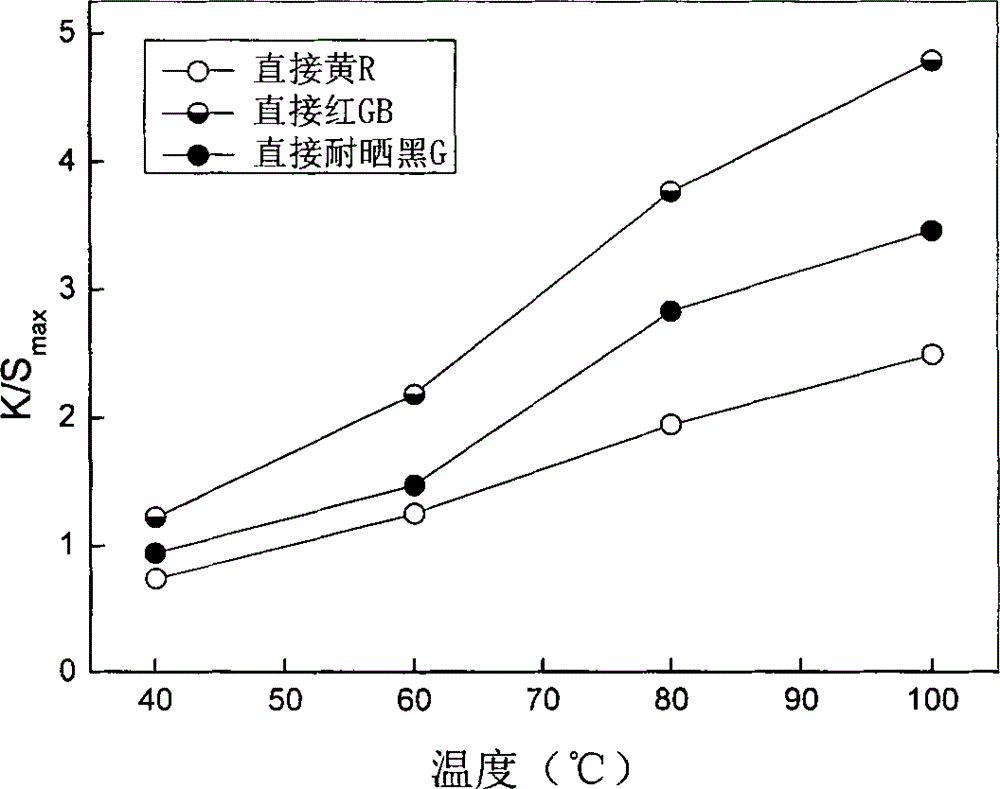

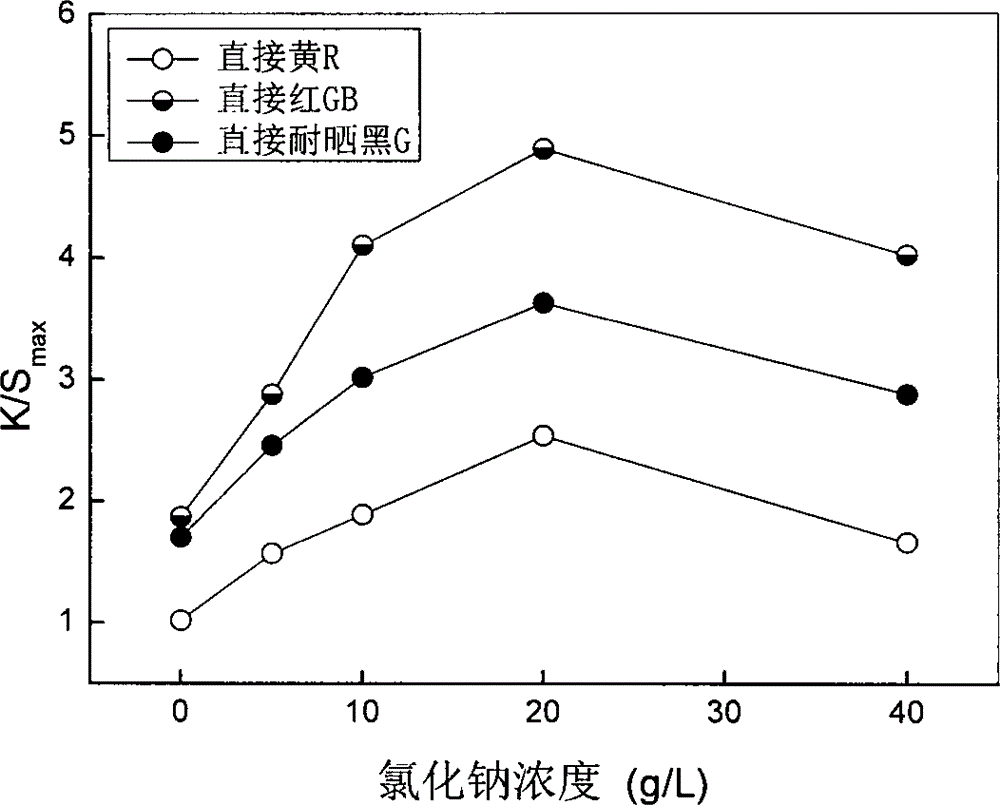

Image

Examples

Embodiment 1

[0018] 1. Pretreatment of polyacrylonitrile fiber wool: under 50°C and stirring conditions, first use an anionic surfactant aqueous solution with a concentration of 2.0g / L to wash and treat polyacrylonitrile fiber wool for 30 minutes, then take it out, wash and dry it;

[0019] 2. The surface modification of polyacrylonitrile fiber wool: accurately weigh the described pretreated polyacrylonitrile fiber wool of specified weight, immerse in the hydroxylamine hydrochloride aqueous solution that concentration is 0.40mol / L, wherein polyacrylonitrile fiber wool weight ( gram) and the volume (milliliter) ratio of hydroxyammonium hydrochloride aqueous solution is 1: 50, then use sodium hydroxide to adjust the pH value of mixture aqueous solution to 5.5-6.0, carry out amido fat modification reaction at 70 ℃ and stirring condition After 2.5 hours, after the reaction, the modified polyacrylonitrile fiber wool was taken out, washed with distilled water for 5 times, dried for later use, and...

Embodiment 2

[0023] 1. The process is the same as Step 1 in Example 1.

[0024] 2. The concentration of hydroxylamine hydrochloride was set at 0.60mol / L, and the amido fat modification reaction was 2.0 hours, and all the other processes were identical with step 2 in embodiment 1.

[0025] 3. The dye solution dyestuff is direct red GB, and all the other are the same as step 3 in embodiment 1.

[0026] 4. The process is the same as step 4 in Example 1, and the obtained polyacrylonitrile fiber yarn dyed sample is abbreviated as sample 2#.

Embodiment 3

[0028] 1. The process is the same as Step 1 in Example 1.

[0029]2. The concentration of hydroxylamine hydrochloride was set at 0.80mol / L, and the amido fat modification reaction was 1.5 hours, and all the other processes were identical with step 2 in embodiment 1.

[0030] 3. The dye solution dye is direct sunfast black G, and the rest are the same as step 3 in Example 1.

[0031] 4. The process is the same as step 4 in Example 1, and the obtained polyacrylonitrile fiber yarn dyed sample is abbreviated as sample 3#.

[0032] In order to investigate the direct dyeing fastness of polyacrylonitrile fiber wool, choose polyacrylonitrile fiber wool dyeing samples in three kinds of embodiments, with reference to national standard GB / T3921.1-5-1997 "textiles-color fastness test-washing resistance Color fastness ", using the soaping fastness tester to measure and grade the fading fastness and staining fastness of the dyed samples, the results are shown in Table 1.

[0033] Table 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com