Method for producing kraft paper by waste newspaper

A production method and waste newspaper technology, which is applied in the processing of waste paper, paper, papermaking, etc., can solve the problems of too many ink spots and the color difference of waste newspapers, etc., and achieve the effect of using waste newspaper resources and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

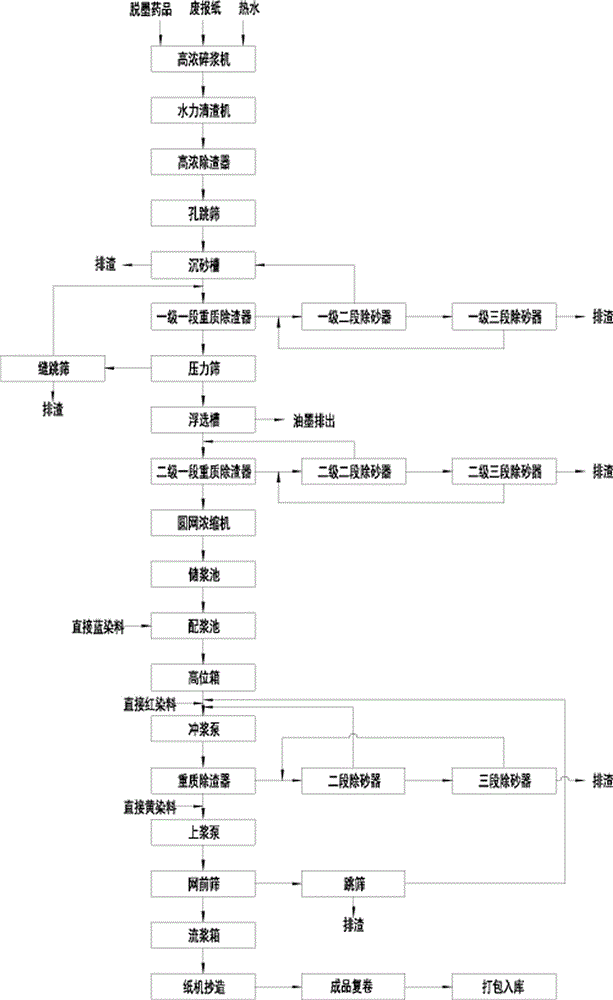

[0056] Embodiment 1: as figure 1 Shown, a kind of waste newspaper produces the production method of kraft paper, it comprises the following steps:

[0057] Step 1): Deinking and pulping the waste newspapers, and storing the prepared pulp in the pulp storage tank;

[0058] Step 2): After the pulp in the pulp storage tank enters the pulp mixing tank, add direct blue dye to the pulp mixing tank;

[0059] Step 3): after the direct blue dyed pulp comes out of the pulp mixing tank, add direct red dye before slag removal;

[0060] Step 4): After the direct red dyed pulp is removed, the direct yellow dye is added;

[0061] Step 5): After the pulp dyed with direct yellow dye passes through the paper machine manufacturing step, the finished product is rewinded and finally packed into the warehouse;

[0062] In step 2), add 0.1kg of direct blue per ton of pulp; in step 3), add 0.5kg of direct red per ton of pulp; in step 4), add 12kg of direct yellow per ton of pulp;

[0063] When ad...

Embodiment 2

[0082] The production steps of Example 2 are basically the same as those of Example 1, with the difference that: in step 2), 0.2 kg of direct blue is added per ton of pulp; in step 3), direct red is added per ton of pulp 0.8kg; in step 4), add 15kg of direct yellow per ton of pulp.

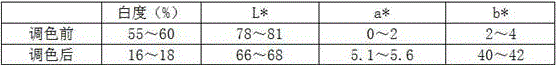

[0083] The kraft paper toning data that embodiment 2 produces is as follows:

[0084]

[0085] Among them, the chromaticity L* represents the brightness of the object; a* represents the red-green value, the positive value is red, and the negative value is green; b* represents the yellow-blue value, the positive value is yellow, and the negative value is blue.

Embodiment 3

[0086] Example 3: The production steps of Example 3 are basically the same as those of Example 1, the difference is that: in the step 2), 0.3kg of direct blue is added per ton of pulp; in the step 3), each ton Add 1kg of direct red to the pulp; in step 4), add 17kg of direct yellow per ton of pulp.

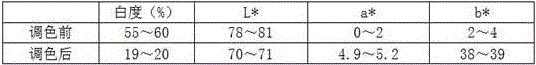

[0087] The kraft paper toning data that embodiment 3 produces is as follows:

[0088]

[0089] Among them, the chromaticity L* represents the brightness of the object; a* represents the red-green value, the positive value is red, and the negative value is green; b* represents the yellow-blue value, the positive value is yellow, and the negative value is blue.

[0090] In Examples 1, 2, and 3, three different dyes are used for color matching, and qualified kraft paper with consistent color is finally produced, which effectively utilizes waste newspaper resources and reduces costs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com