Anti-scraping and anti-wear color coated steel plate

A color-coated steel plate, wear-resistant layer technology, applied in coatings, layered products, polyester coatings, etc., can solve the problems of poor scratch resistance and wear resistance, affecting product quality, poor practical performance, etc., to achieve scratch resistance Strong strength, improved scratch resistance, improved wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

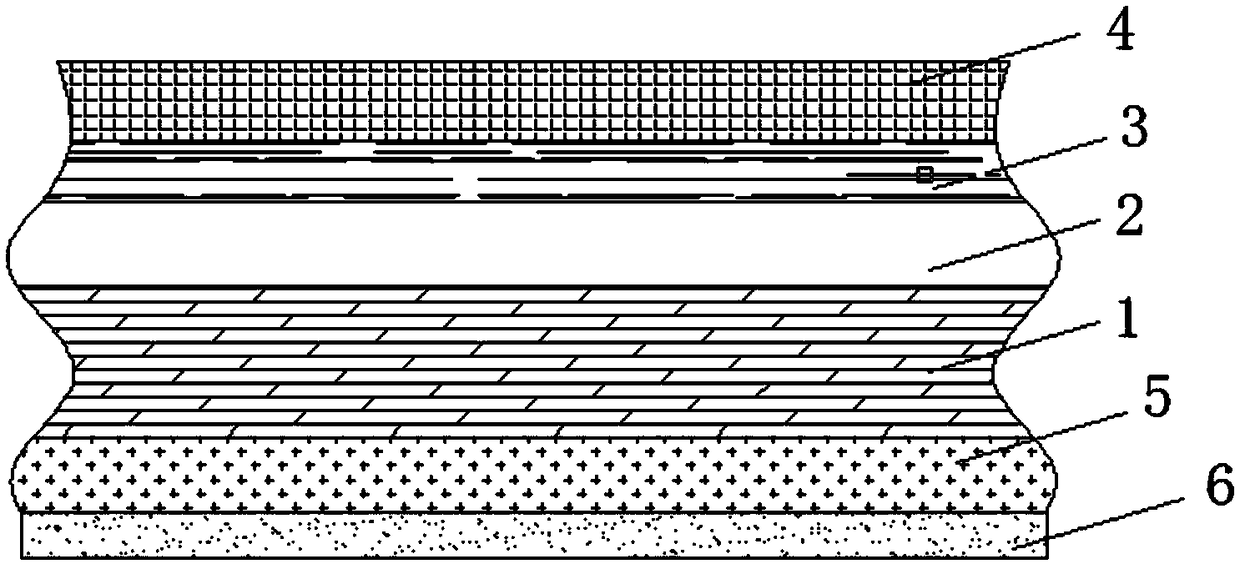

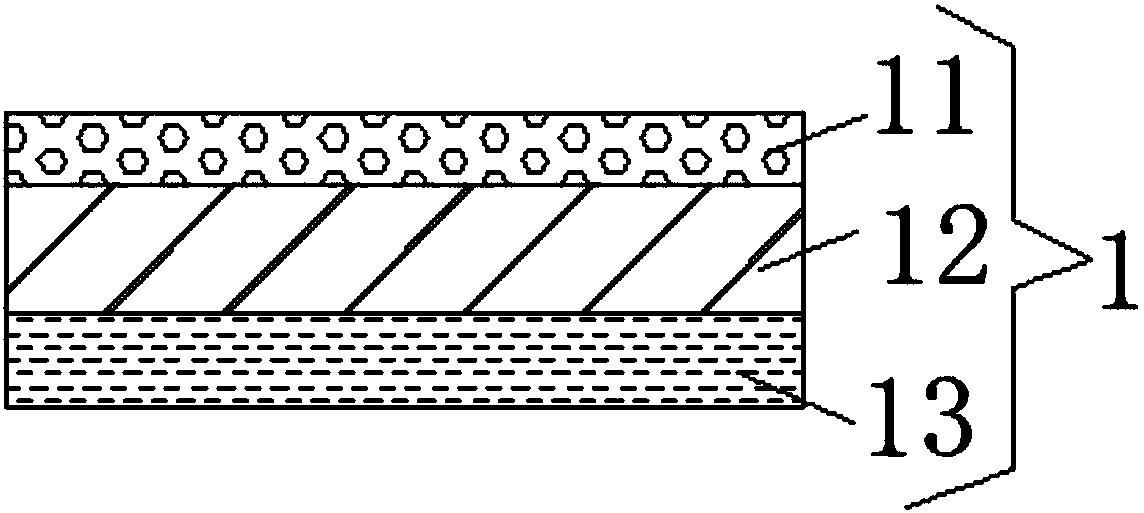

[0027] A scratch-resistant and wear-resistant colored coated steel plate, comprising a base plate 1, the base plate 1 comprises a low-carbon steel plate 11, a hot-dip galvanized layer 12 and an alloy wear-resistant layer 13, and the lower surface of the low-carbon steel plate 11 is laminated with an alloy-resistant Wear layer 13, the lower surface of the alloy wear-resistant layer 13 is laminated with a hot-dip galvanized layer 12, the upper surface of the low-carbon steel plate 11 is laminated with a scratch-resistant wear-resistant layer 2, and the scratch-resistant wear-resistant layer 2 The top is coated with a topcoat layer 3, the outer surface of the topcoat layer 3 is provided with a protective layer 4, the lower surface of the hot-dip galvanized layer 12 is provided with a chemical reaction layer 5, and the lower end of the chemical reaction layer 5 is coated with Primer layer6.

[0028] Method step is the same as embodiment 1, and different processing parameters are a...

Embodiment 3

[0033] A scratch-resistant and wear-resistant colored coated steel plate, comprising a base plate 1, the base plate 1 comprises a low-carbon steel plate 11, a hot-dip galvanized layer 12 and an alloy wear-resistant layer 13, and the lower surface of the low-carbon steel plate 11 is laminated with an alloy-resistant Wear layer 13, the lower surface of the alloy wear-resistant layer 13 is laminated with a hot-dip galvanized layer 12, the upper surface of the low-carbon steel plate 11 is laminated with a scratch-resistant wear-resistant layer 2, and the scratch-resistant wear-resistant layer 2 The top is coated with a topcoat layer 3, the outer surface of the topcoat layer 3 is provided with a protective layer 4, the lower surface of the hot-dip galvanized layer 12 is provided with a chemical reaction layer 5, and the lower end of the chemical reaction layer 5 is coated with Primer layer6.

[0034] Method step is the same as embodiment 1, and different processing parameters are a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com