Method for improving color brightness of non-rainbow structural color

A technology of color brightness and structural color, applied in optical components, optics, instruments, etc., can solve problems such as brightness reduction, and achieve the effect of improving color brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

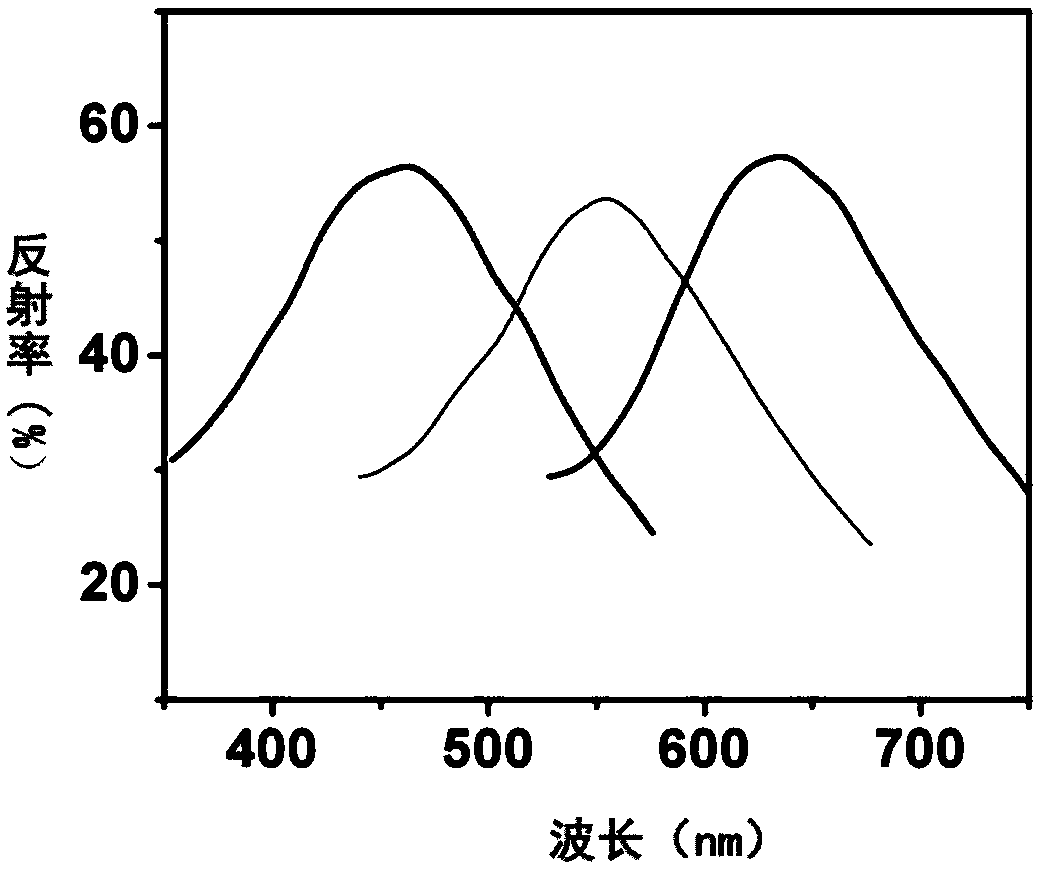

[0020] Monodisperse polystyrene-polymethyl methacrylate-polyacrylic acid colloidal microspheres with a particle size of 210 nm at a mass fraction of 10%, polystyrene-polymethyl methacrylate-polyacrylic acid with a particle size of 210 nm Polystyrene-polymethyl methacrylate-polyacrylic acid colloidal microspheres with a particle size of 1 / 20 of the mass of the acrylic colloidal microspheres are 250 nm, and the particle size of 1% of the mass fraction of the above-mentioned colloidal microspheres is 2 µm Graphene and graphene quantum dots (particle size 50nm) with a mass fraction of 10% of graphene are evenly mixed and dispersed in water to form an emulsion, and then the above emulsion is placed in a commercial spray pen and sprayed onto the On the substrate, after drying at room temperature, a high-brightness green non-iridescent structural color film ( figure 1 ). It has a typical disordered optical structure ( figure 2 ), the reflection peak of its reflection spectrum is ...

Embodiment 2

[0022] Monodisperse polystyrene-polymethyl methacrylate-polyacrylic acid colloidal microspheres with a particle size of 250 nm at a mass fraction of 10%, polystyrene-polymethyl methacrylate-polyacrylic acid with a particle size of 250 nm Polystyrene-polymethyl methacrylate-polyacrylic acid colloidal microspheres with a particle size of 1 / 20 of the mass of acrylic colloidal microspheres are 180 nm, and the particle size of 1% of the mass fraction of the above colloidal microspheres is 5 µm Graphene and graphene quantum dots (particle size 50nm) with a mass fraction of 10% of graphene were uniformly mixed and dispersed in water to form an emulsion. Then, the emulsion is placed in a commercial airbrush, sprayed onto the substrate by spraying, and after drying at room temperature, a high-purity red non-iridescent structural color film ( figure 1 ), the reflection peak of its reflection spectrum is located at 633 nm ( image 3 ).

Embodiment 3

[0024]Monodisperse polystyrene-polymethyl methacrylate-polyacrylic acid colloidal microspheres with a particle size of 180 nm at a mass fraction of 10%, polystyrene-polymethyl methacrylate-polyacrylic acid with a particle size of 180 nm Polystyrene-polymethyl methacrylate-polyacrylic acid colloidal microspheres with a particle size of 1 / 20 of the mass of the acrylic colloidal microspheres are 250 nm, and the particle size of 1% of the mass fraction of the above-mentioned colloidal microspheres is 5 µm Graphene and graphene quantum dots (particle size 50nm) with a mass fraction of 10% of graphene were uniformly mixed and dispersed in water to form an emulsion. Then, the emulsion is placed in a commercial airbrush, sprayed onto the substrate by spraying, and after drying at room temperature, a high-brightness blue non-iridescent structural color film ( figure 1 ), the reflection peak of its reflection spectrum is located at 452 nm ( image 3 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com