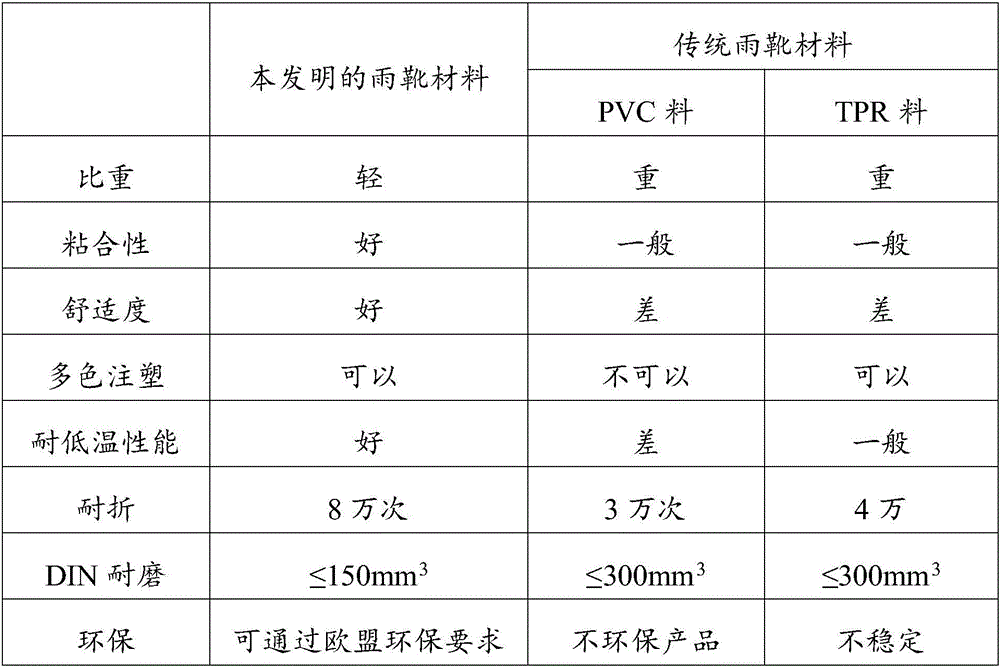

Processing method of rain boot material, rain boot material, rain boot and rain boot processing method

A processing method and technology for rain boots, applied in the application, clothing, footwear and other directions, can solve the problems of low production efficiency of rain boots, long-term cooling and cooling, poor wear resistance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The concrete processing method of the present embodiment is as follows:

[0057] (1) Preparation of oil-extended glue:

[0058] Styrene-Butadiene-Styrene Block Copolymer 80g naphthenic oil 50g mixing temperature 40℃ mixing time 3 hours

[0059] (2) Preparation of maleic anhydride modified polyolefin elastomer:

[0060] Dow 8402 50g Dow 8480 50g Dow 9107 50g maleic anhydride 2g dicumyl peroxide 0.5g Melting section temperature 200℃

[0061] (3) Preparation of hard material:

[0062] Oil-extended glue 130g polystyrene 20g K resin 25g Polyphenylene ether 20g Maleic anhydride modified polyolefin elastomer 10g Melting section temperature 180℃

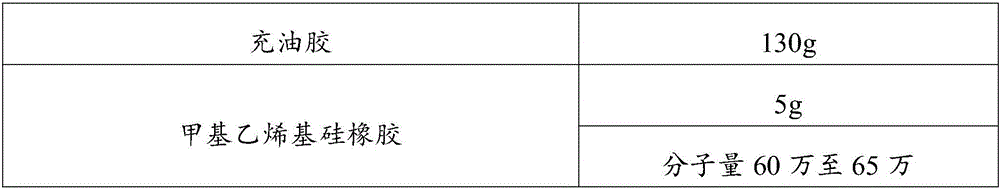

[0063] (4) Preparation of soft material:

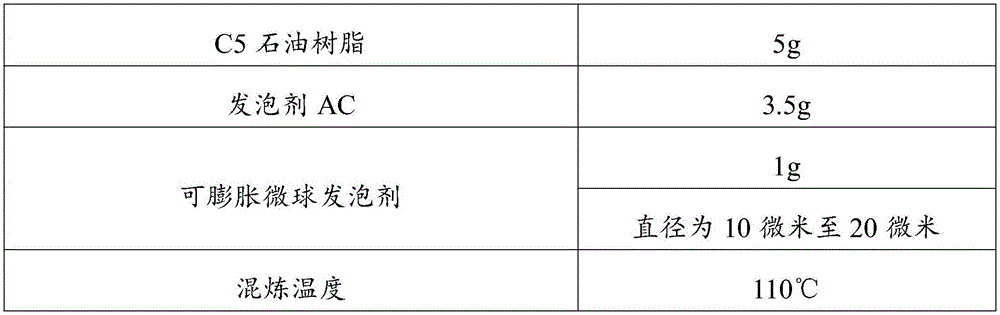

[0064]

[0065]

[0066] (5) Mechanically mix the hard material and the soft material according to the weight ratio of 1:2 to obtain the rain boot material. Ra...

Embodiment 2

[0069] The concrete processing method of the present embodiment is as follows:

[0070] (1) Preparation of oil-extended glue:

[0071] Styrene-Butadiene-Styrene Block Copolymer 50g white mineral oil 20g mixing temperature 80℃ mixing time 3 hours

[0072] (2) Preparation of maleic anhydride modified polyolefin elastomer:

[0073] Dow 8402 150g Dow 8200 50g maleic anhydride 7g dicumyl peroxide 0.05g Melting section temperature 150℃

[0074] (3) Preparation of hard material:

[0075] Oil-extended glue 70g polystyrene 30g K resin 26g Polyphenylene ether 5g heavy calcium powder 10g Maleic anhydride modified polyolefin elastomer 30g Melting section temperature 280℃

[0076] (4) Preparation of soft material:

[0077]

[0078] (5) Mechanically mix the hard material and the soft material according to the weight ratio of 2:1 to obtain the rain boot material. ...

Embodiment 3

[0081] The concrete processing method of the present embodiment is as follows:

[0082] (1) Preparation of oil-extended glue:

[0083] Styrene-Butadiene-Styrene Block Copolymer 75g naphthenic oil 45g mixing temperature 50℃ mixing time 2 hours

[0084] (2) Preparation of maleic anhydride modified polyolefin elastomer:

[0085] Dow 8402 90g Dow 8480 45g Dow 8200 35g Dow 9107 30g maleic anhydride 3g dicumyl peroxide 0.1g Melting section temperature 190℃

[0086] (3) Preparation of hard material:

[0087] Oil-extended glue 120g polystyrene 22g K resin 24g Polyphenylene ether 15g heavy calcium powder 2g Maleic anhydride modified polyolefin elastomer 15g Melting section temperature 200℃

[0088] (4) Preparation of soft material:

[0089]

[0090]

[0091](5) Mechanically mix the hard material and the soft material according to the weight ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com