Device and method for measuring verticality

A verticality and measuring tool technology, applied in measuring devices, mechanical measuring devices, instruments, etc., can solve problems such as difficulty in adjustment, affecting inspection quality, and complex inspection, to meet inspection needs, improve inspection accuracy, and adjust Easy to detect effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

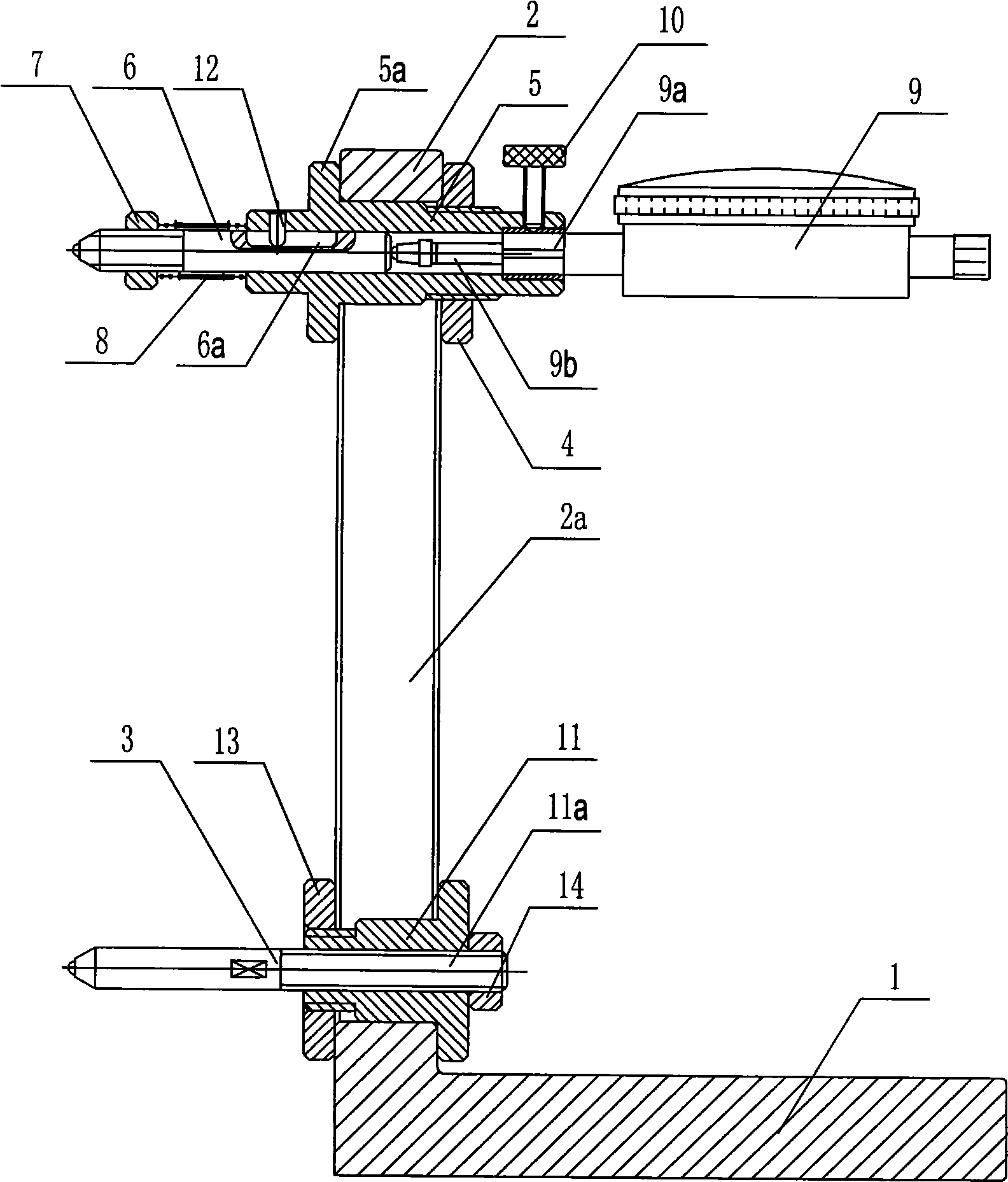

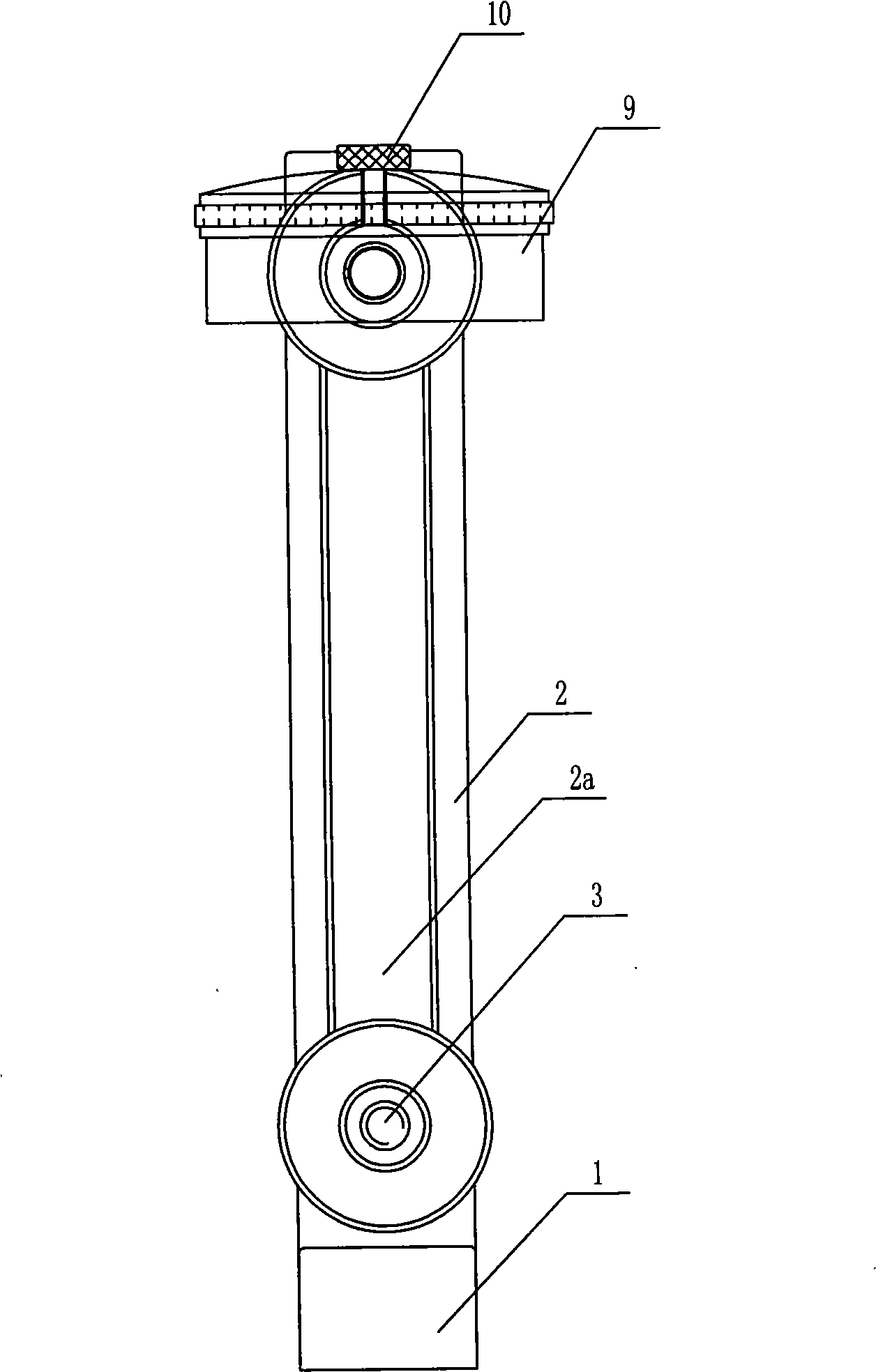

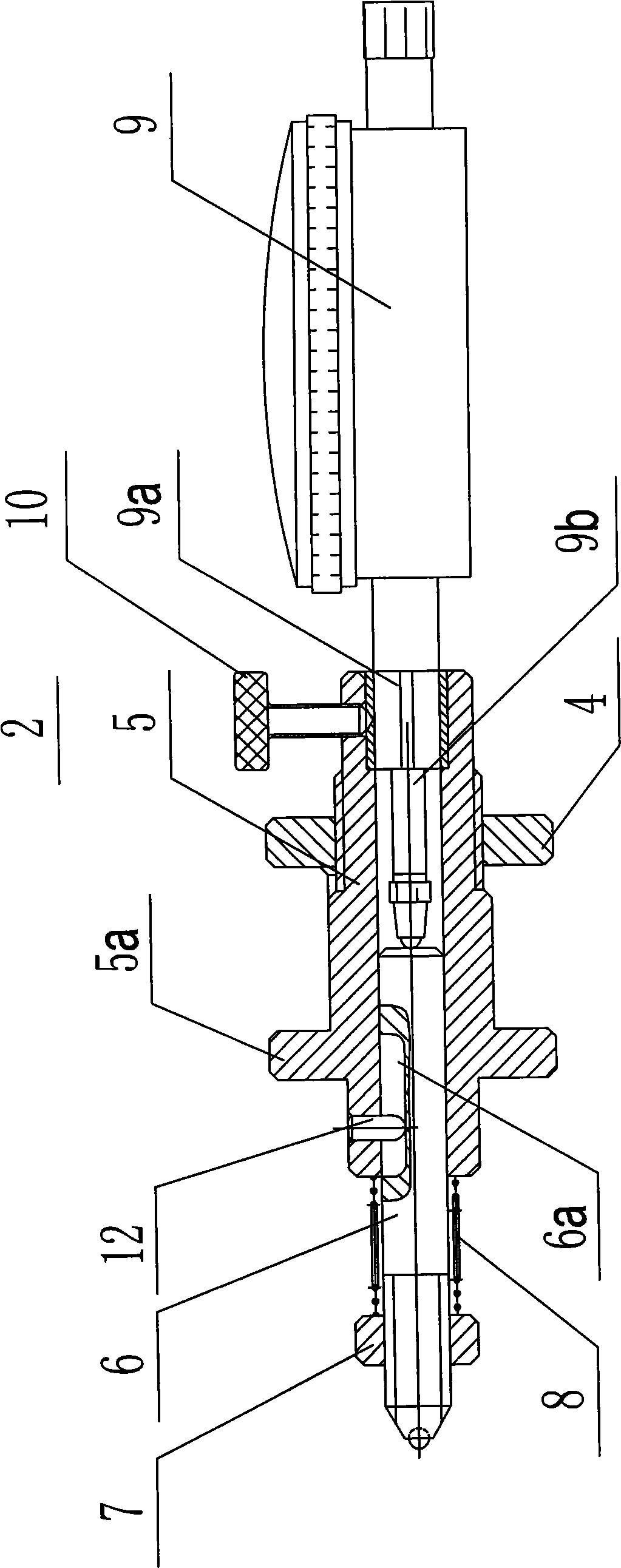

[0035] Such as figure 1 , 2 Shown in , 3: a kind of perpendicularity measuring instrument, is provided with horizontal base 1, and vertical support 2 is fixed on this horizontal base 1, and described vertical support 2 is arranged according to upper and lower, and benchmark detection mechanism and deviation detection mechanism are installed , a vertical strip-shaped through hole 2a is opened on the vertical pillar 2;

[0036] The horizontal positioning rod 3 in the deviation detection mechanism is installed on the vertical pillar 2 through the lower sliding body 11 and the nut, and the horizontal positioning rod 3 stretches out from the vertical strip-shaped through hole 2a;

[0037] Many existing workpieces are mostly special-shaped parts, such as the verticality detection of crankcase, cylinder head, cylinder head, etc., through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com