Prefabricated beam-column connection in prefabricated concrete buildings and construction method thereof

A technology of concrete construction and beam-column connection, which is applied in construction, building structure, and building material processing, and can solve problems such as increasing the difficulty of transportation and storage of prefabricated columns, affecting the integrity of the frame structure, and affecting the penetration of column reinforcement. Achieve the effects of high construction flexibility, shortened construction period, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

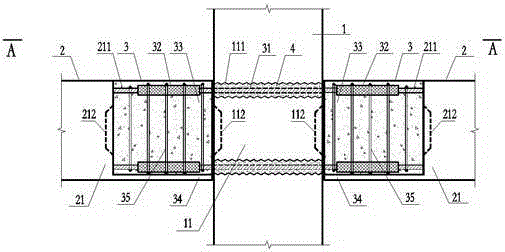

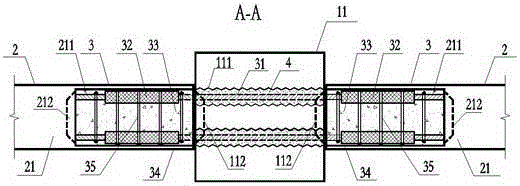

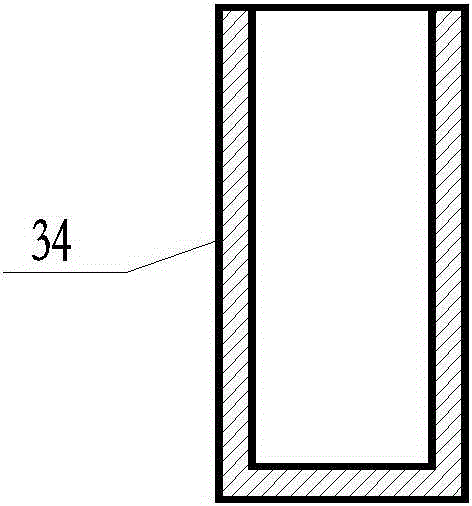

[0034] like figure 1 , figure 2As shown, a prefabricated beam-column connection node in a prefabricated concrete building includes a prefabricated column 1, a prefabricated beam 2, and a node connecting member 3 connecting the prefabricated column 1 and the prefabricated beam 2. The prefabricated column 1 has a column connecting portion 11, and the column is connected The part 11 reserves a through hole 111 along the axial direction of the prefabricated beam 2, the hole wall of the through hole 111 is rough, and the keyway A112 is provided on the connecting surface of the column connecting part 11; the prefabricated beam 2 has a beam connecting end 21, and the beam longitudinal Ribs 211, one end of the beam longitudinal ribs 211 protrudes from the end face of the beam connecting end 21, and the end face of the beam connecting end 21 is provided with a keyway B212; on the end face of the beam connecting end 21, there is a U-shaped dismantling-free formwork 34 prefabricated int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com