Process and equipment for deacidifying whole paper document

A deacidification and paper technology, applied in the post-processing of waste paper, etc., can solve the problems of paper document damage, low paper stiffness, paper bending and collapse, and achieve the effect of eliminating damage, reducing damage and deacidification. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

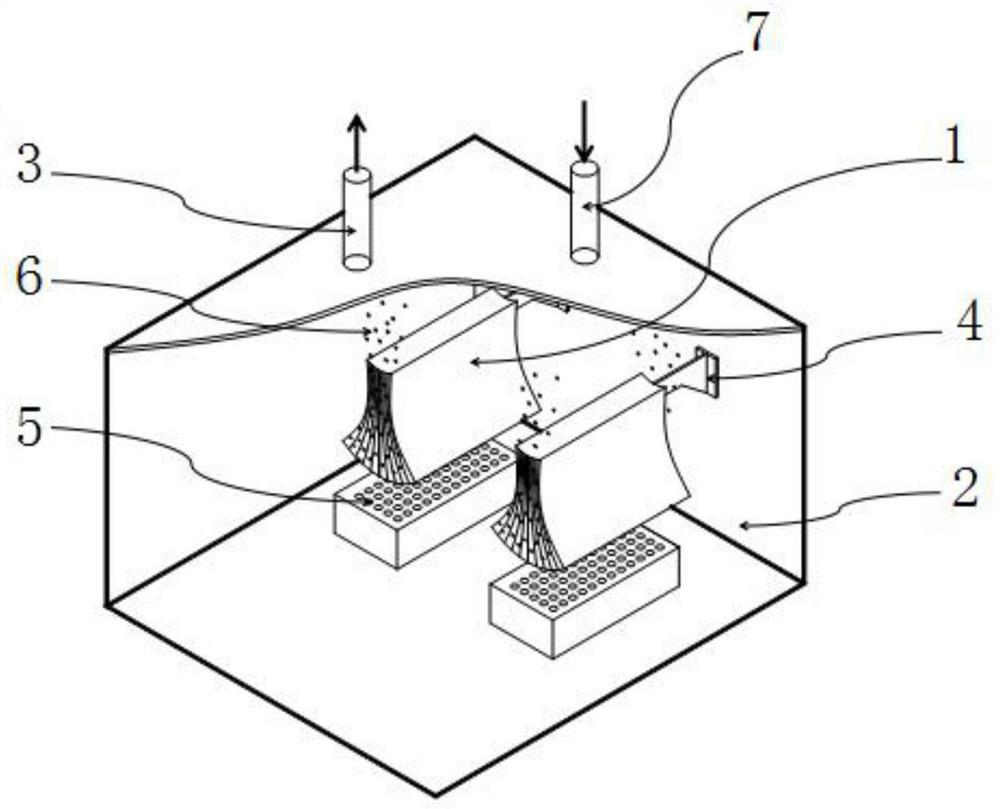

Image

Examples

Embodiment 1

[0038] This embodiment provides a process for soaking and deacidifying the entire paper document 1 by using an organic suspension type deacidification solution (hereinafter referred to as "deacidification solution"), which mainly includes the following steps:

[0039] S1. Separate the entire paper document 1 from the middle page, place the entire paper document 1 on a horizontal fixed frame with its back upwards, and be constrained to position it; When the deacidification solution is separated from the paper documents, the pages in the separated state will naturally sag under the influence of their own weight, and the paper will not bend, collapse and overlap;

[0040] S2. The fixed frame is placed in a sealable deacidification tank together with paper documents;

[0041]S3. Inject the organic suspension type deacidification solution into the airtight deacidification tank, so that the deacidification solution is completely immersed in the paper documents;

[0042] S4. Dischar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com