Manufacturing method of inner support steel structure special-shaped column

A manufacturing method and technology of special-shaped columns, which are applied in the direction of pillars, columns, pier columns, etc., can solve the problems of poor resistance to twisting and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

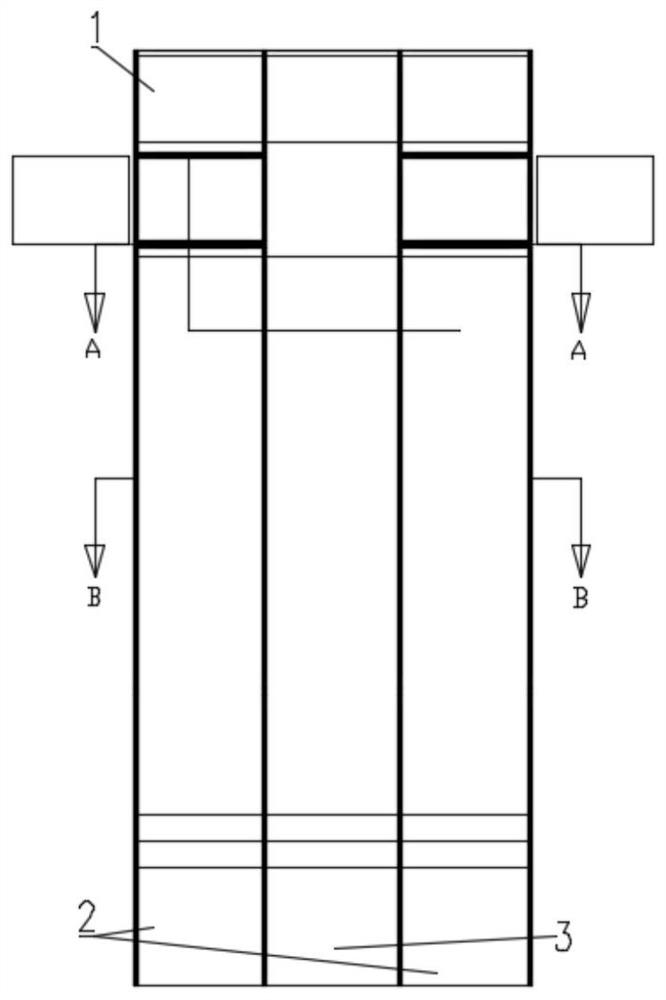

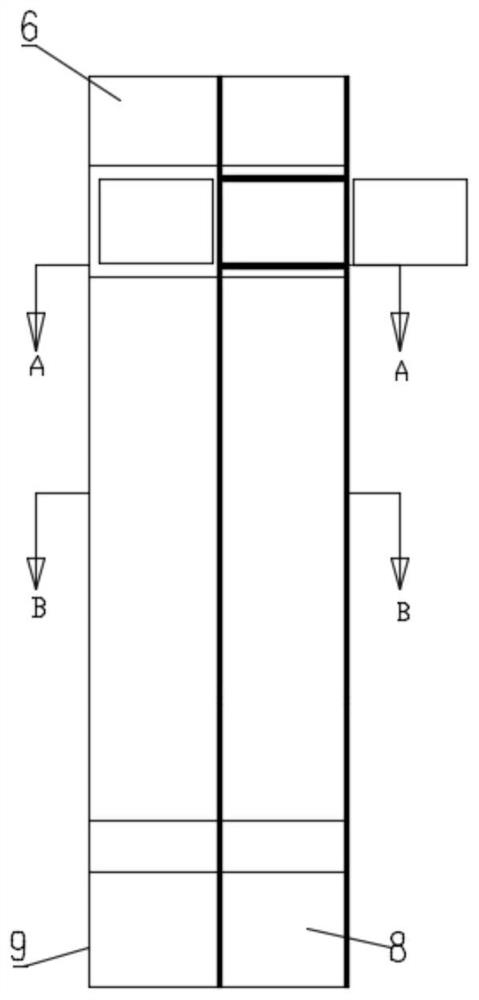

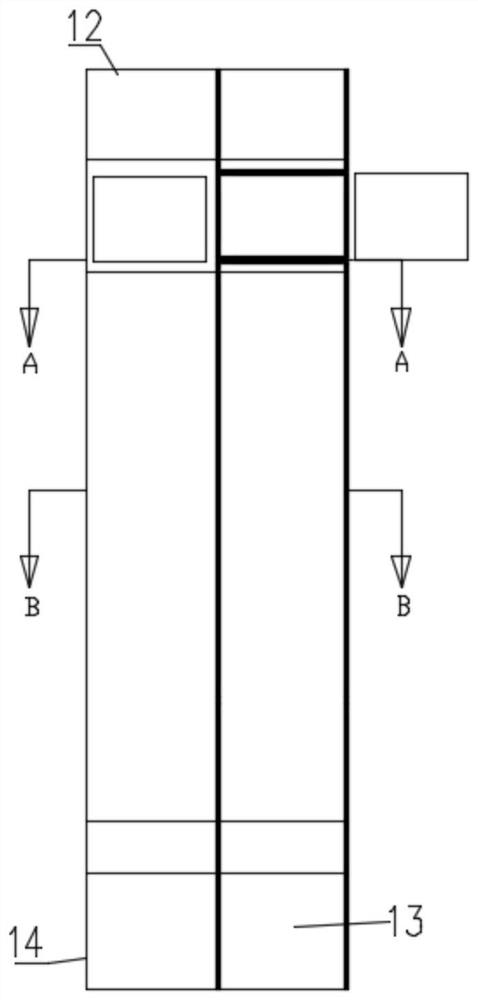

[0050] Such as Figure 1-12 As shown, in the embodiment of the present invention, a special-shaped column of an internally supported steel structure includes a central column 1, a side column 6 and a corner column 12, and a plurality of central columns 1 are connected around the central column 1, and multiple columns are arranged at the edge of the building. A side column 6, between the side column 6 and the side column 6 is provided with a corner column 12 for connecting the middle column 1 and the side column 6, between the middle column and the middle column, between the center column and the side column and the middle column side column and the side column. The corner columns are connected by H-shaped steel beams and reinforced by scissors support. The center column support assembly is provided in the center column 1, the side column support assembly is provided in the side column 6, and the corner column support assembly is provided in the corner column 12.

[0051] The c...

Embodiment 2

[0053] Such as Figure 1-12 As shown, in the embodiment of the present invention, the manufacturing method of the special-shaped column of the inner support steel structure, the steps are as follows:

[0054] S1. The production and assembly of each column in the special-shaped column of the inner support steel structure;

[0055] S2, the production and assembly of the central column 1;

[0056] S201. First, according to the cross column process method and manufacturing steps, the inner support web 4 of the material column and the center column flange plate 3 are assembled and welded to form a cross column member;

[0057] S202. Cutting the center column flange restraint plate 2 and the center column inner horizontal support stiffener plate 5, weld the center column inner horizontal support stiffener plate 5 at the corresponding position in the cross column member, and fill the cavity of the center column 1 with light weight After the concrete 7 is completely dried, the cente...

Embodiment 3

[0071] Such as Figure 1-12 As shown, in the embodiment of the present invention, the manufacturing method of the special-shaped column with eccentric inner support steel structure, the steps are as follows:

[0072] S1. The production and assembly of each column in the special-shaped column of eccentric inner support steel structure;

[0073] S2. Fabrication and assembly of the center column 1 of the eccentric inner support;

[0074] S201. First, according to the cross column process method and manufacturing steps, the eccentric inner support web 4 and the flange plate 3 of the material column are assembled and welded to form an eccentric cross column member;

[0075] S202, then blank the center column flange restraint plate 2 and the center column eccentric inner horizontal support stiffener plate 5, weld the center column eccentric inner horizontal support stiffener plate 5 at the corresponding position in the eccentric cross column member, and place it in the cavity of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com