Laser cutting nozzle

A laser cutting and cutting nozzle technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of damaging the lens and reducing the service life of the lens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

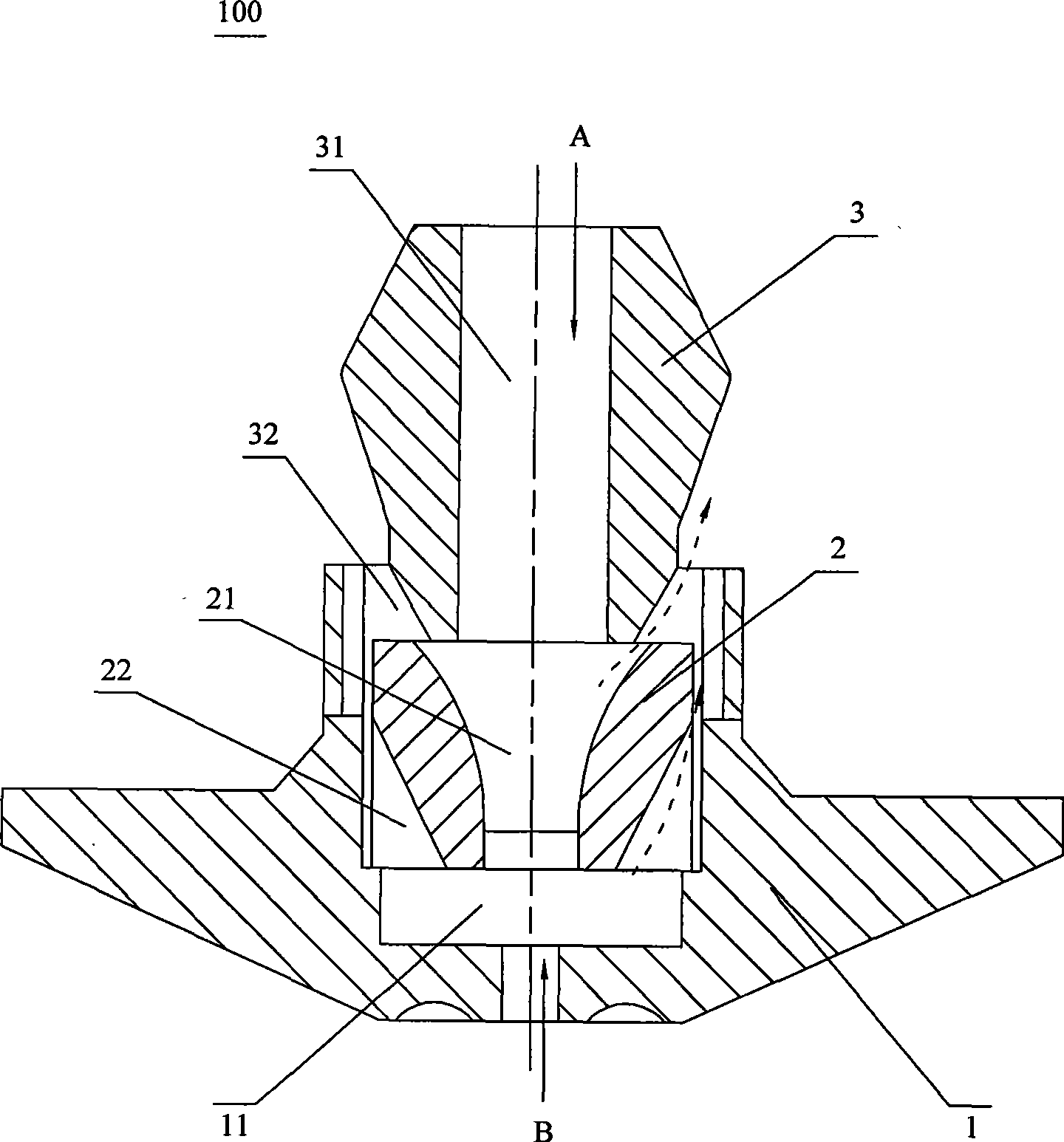

[0023] see figure 1 , is a structural schematic diagram of the laser cutting nozzle of the present invention. In order to reduce and prevent the oxidized slag (not shown) generated during laser cutting from damaging the lens, thereby reducing the service life of the lens, the laser cutting nozzle 100 mainly It includes a cutting nozzle main body 1, a concentrator 2 fixed in the cutting nozzle main body 1 and a slag return device 3, wherein the slag return device 3 is adjacent to the flow concentrator 2, in fact, the slag return device 3 , concentrator 2 and cutting nozzle main body 1 are arranged in sequence.

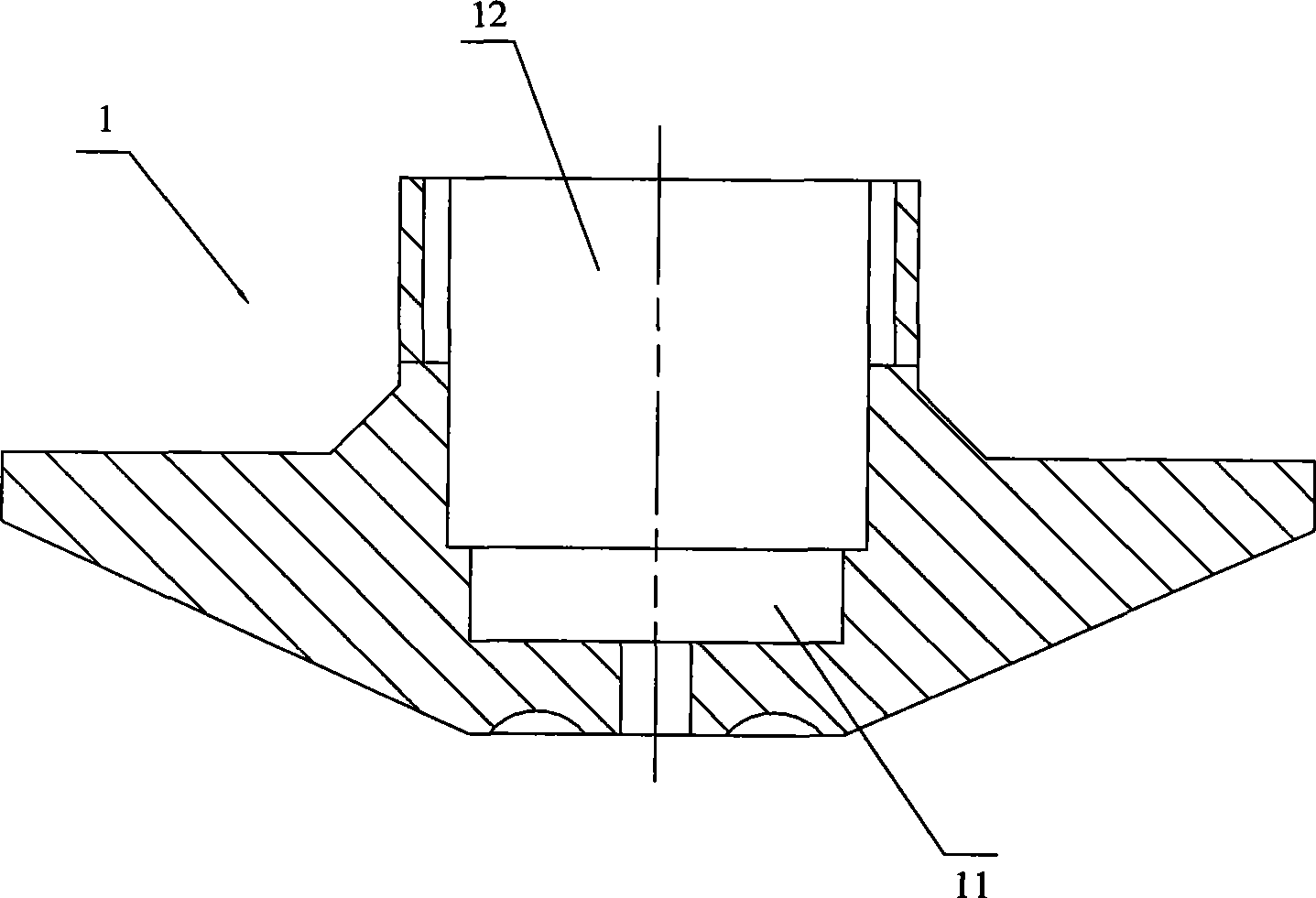

[0024] Among them, such as figure 1 and figure 2 , the cutting nozzle main body 1 is used to cut the workpiece, including: a first storage cavity 11 and a storage space 12 connected with the first storage cavity 11, wherein the concentrator 2 and the slag returner 3 are adjacent to each other and are fixed in the storage space. In space 12.

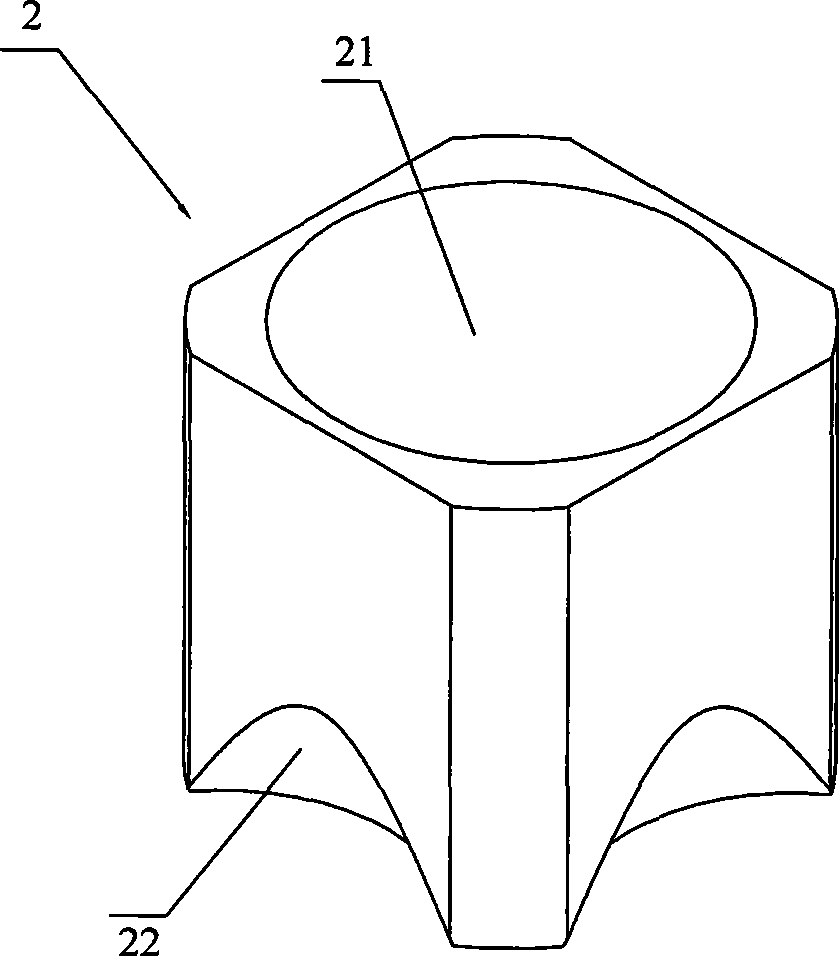

[0025] Among them, suc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com