Preparation method of rice flour noodles with low noodle breaking rate and quality modifying agent thereof

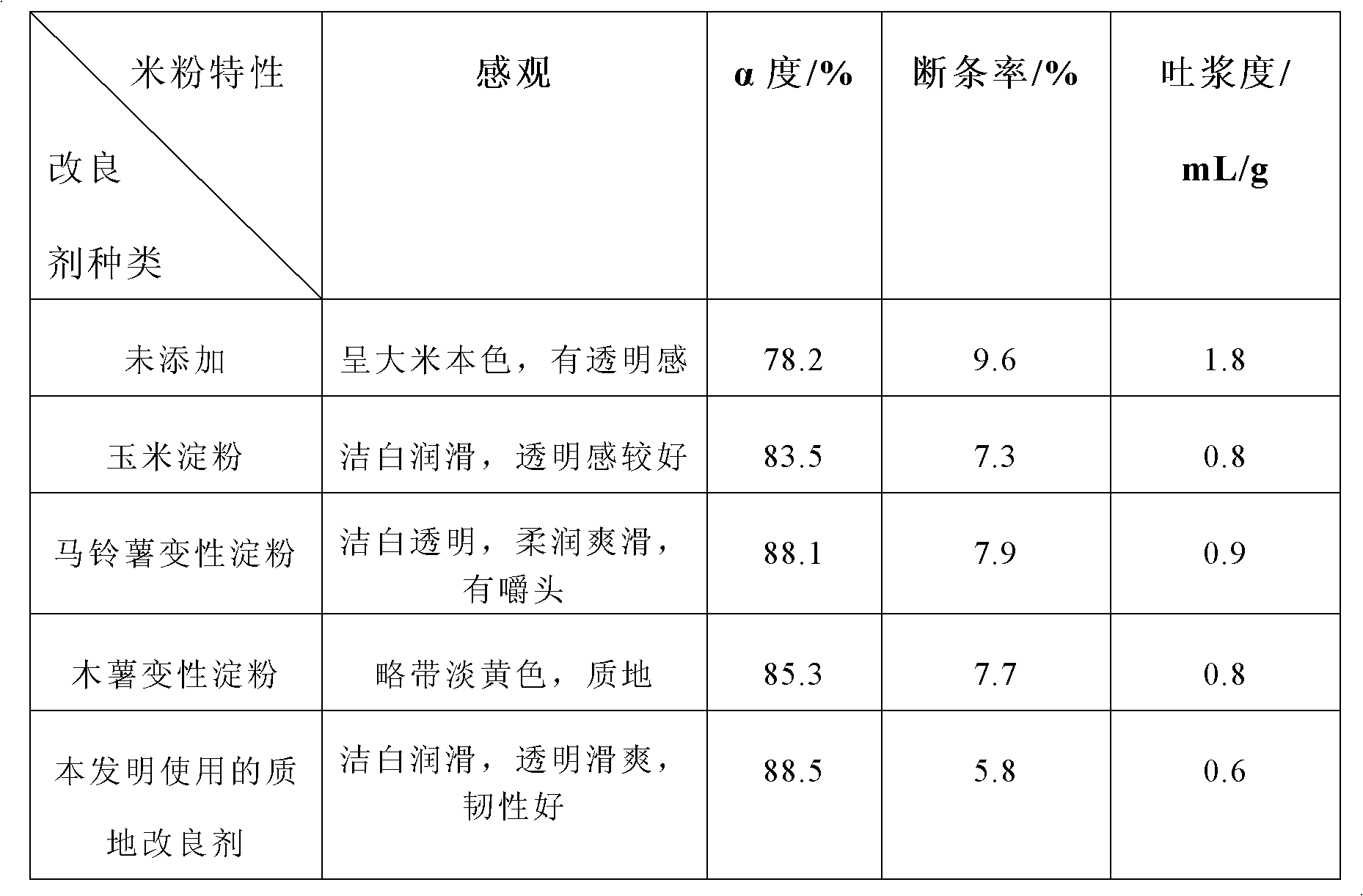

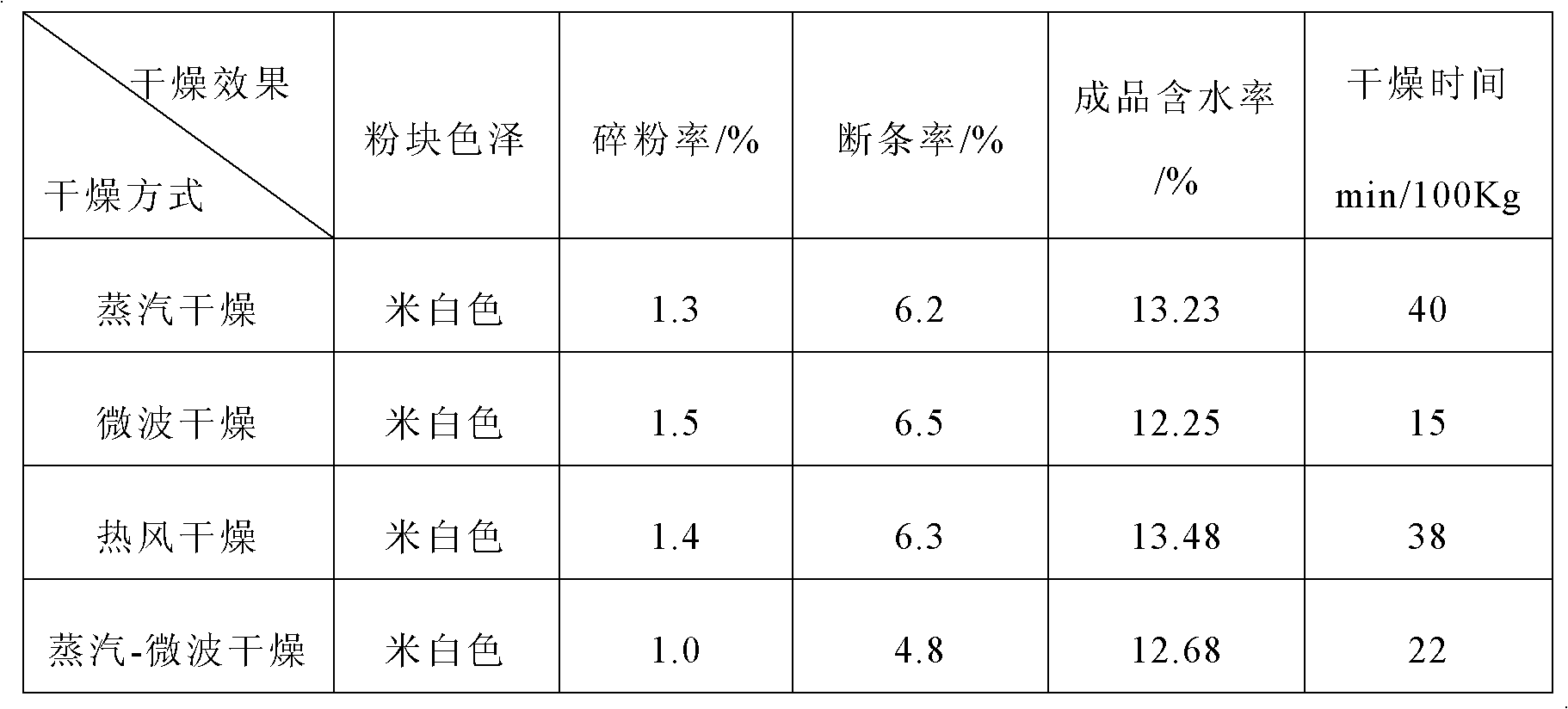

A technology of broken strips and rice vermicelli, which is applied in the field of preparation method and texture improver of rice vermicelli with low broken strips rate, can solve the problem that the improvement effect of broken strips of rice vermicelli is not obvious, threatens the health of consumers, and uses chemical raw materials and other issues to achieve the effect of large market potential, moderate price, and increased toughness and stickiness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Weigh cornstarch, kudzu starch and carrageenan respectively according to the mass ratio of 0.5:1:0.1, and then mix them uniformly to obtain the rice vermicelli texture improver.

[0036] (2) Get 100 kg of rice raw material, and use an emery roller rice mill to remove impurities and metals. Add water to soak the rice after removing impurities and whitening for 40 minutes, and the consumption of water is 5 times of the weight of the rice after removing impurities and whitening. Then use a refiner to refine and pass through a 90-mesh sieve to obtain rice milk. Then use the vacuum dehydration drum to dehydrate the rice milk to obtain rice flour with a moisture content of 44wt%. Then the rice flour is poured into a stirring rice steamer, and the rice vermicelli natural texture improver whose consumption is 7wt% of the total weight of the rice flour is added, and mixed evenly to obtain the powder. Introduce 0.25Mpa steam into the powder for initial steaming for 7 minute...

Embodiment 2

[0038] (1) Weigh cornstarch, kudzu starch and carrageenan at a mass ratio of 1:0.5:0.3, and then mix them uniformly to obtain a natural texture improver for rice vermicelli.

[0039] (2) Get 100 kg of rice raw material, and use an emery roller rice mill to remove impurities and metals. Add water to soak the rice after removing impurities and whitening for 50 minutes, and the consumption of water is 7.5 times of the weight of the rice after removing impurities and whitening. Then use a refiner to refine and pass through a 100-mesh sieve to obtain rice milk. Then use the vacuum dehydration drum to dehydrate the rice milk to obtain rice flour with a moisture content of 38wt%. Then the rice flour is poured into a stirring rice steamer, and the rice vermicelli natural texture improver whose consumption is 4wt% of the total weight of the rice flour is added, and mixed evenly to obtain the powder. Introduce 0.4Mpa steam into the powder for initial steaming for 7.5 minutes, so that ...

Embodiment 3

[0041] (1) Weigh cornstarch, kudzu starch and carrageenan respectively according to the mass ratio of 1.5:1.5:0.2, and then mix them evenly to obtain the natural texture improver of rice vermicelli.

[0042](2) Get 100 kg of rice raw material, and use an emery roller rice mill to remove impurities and metals. Adding water to soak the rice after removing impurities and whitening for 30 minutes, the consumption of water is 10 times of the weight of the rice after removing impurities and whitening. Then use a refiner to refine and pass through an 80-mesh sieve to obtain rice milk. Then use the vacuum dehydration drum to dehydrate the rice milk to obtain rice flour with a moisture content of 41wt%. Then, the rice flour is poured into a stirring flour steamer, and the rice vermicelli natural texture improver whose consumption is 10wt% of the total weight of the rice flour is added, and mixed evenly to obtain the powder. Introduce 0.1Mpa steam into the powder for initial steaming ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com